Industry Overview

In the fast-growing beauty and personal care industry, a reliable cosmetic production line is crucial for ensuring consistent product quality, efficiency, and scalable manufacturing. From skincare and haircare to makeup and body care products, modern cosmetic production relies on precision engineering, hygienic design, and automated manufacturing solutions to meet the demands of brands worldwide. As consumer expectations continue to rise, manufacturers must deliver products that are not only high-quality but also safe, innovative, and compliant with international standards such as GMP and ISO certifications.

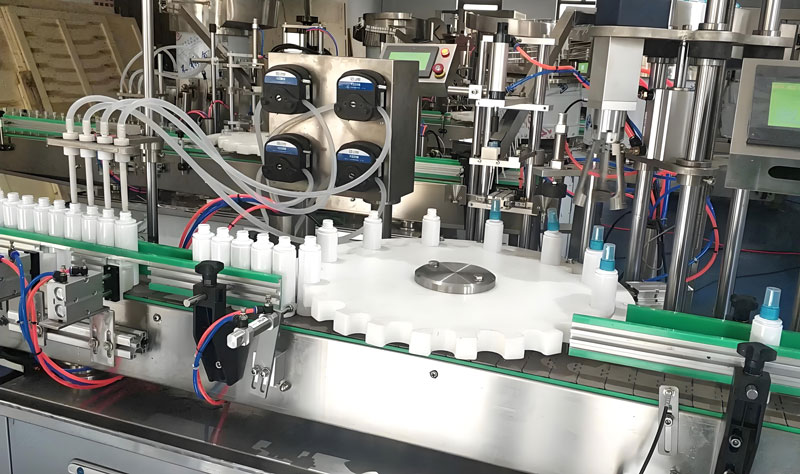

A professional cosmetic production line manufacturer provides solutions that cover the entire process—from raw material handling, mixing, and formulation to filling, capping, labeling, and packaging. Advanced automation and intelligent control systems help reduce manual labor, minimize errors, and maintain batch-to-batch consistency. Additionally, hygienic design with food-grade stainless steel equipment and CIP cleaning systems ensures that every product meets strict sanitation and safety standards. By integrating flexible, modular, and scalable equipment, cosmetic brands can efficiently expand their product lines and respond quickly to market trends, making modern cosmetic production lines an essential investment for growth and competitiveness.

Main Equipment

All equipment is manufactured from food-grade stainless steel and complies with GMP cleanliness standards. It can be **custom-designed** according to the customer's product type, production capacity requirements (500–50,000 bottles/day), and factory layout to achieve intelligent, low-energy, and high-efficiency modern cosmetic production.

Pain Points & Solutions

Common Pain Points

- ◉ Inconsistent product texture and stability due to poor emulsification

- ◉ High product waste and inaccurate filling volumes

- ◉ Labor-intensive packaging processes increase costs

- ◉ Lack of traceability and quality control in manual systems

- ◉ Difficult to scale production for growing brand demand

Our Solutions

- ◉ Advanced high-shear emulsifiers ensure uniform, stable formulations

- ◉ Precision filling systems with ±1% accuracy reduce material waste

- ◉ Automated packaging lines cut labor costs by up to 60%

- ◉ Integrated PLC control with batch tracking and error detection

- ◉ Modular design allows easy expansion from 500 to 50,000 units/day

Success Cases

Our cosmetic production lines are trusted by indie brands, contract manufacturers, and global beauty companies. Here are real examples of how our solutions transformed their operations:

Case 1: Premium Skincare Brand – Automated Cream Line

A fast-growing organic skincare brand in Europe was struggling with inconsistent cream quality and manual filling bottlenecks. We provided a complete 200L emulsion system with automatic cream filler and capping machine. Results:

- ◉ Product rejection rate dropped from 8% to under 1%

- ◉ Production capacity increased from 200 to 1,500 units per day

- ◉ Formulation stability improved, extending shelf life by 3 months

The brand successfully launched in 12 new countries within a year, crediting the new line for consistent quality and scalability.

Case 2: Contract Manufacturer – Turnkey Liquid Filling Line

A contract manufacturer in Southeast Asia needed to handle multiple client formulas with quick changeovers. We delivered a flexible turnkey line with interchangeable nozzles, CIP cleaning, and recipe-based PLC control. Benefits:

- ◉ Changeover time reduced from 4 hours to 30 minutes

- ◉ Ability to produce 15+ different products per day

- ◉ Client audit pass rate improved to 100% due to full traceability

The manufacturer secured 7 new high-profile clients within 6 months, citing reliability and compliance as key factors.

Case 3: Eco-Friendly Beauty Startup – Compact Sustainable Line

An eco-conscious beauty startup required a small footprint, energy-efficient production line for serums and toners. We designed a compact 500L system with solar-ready electrical components and water-saving CIP. Outcomes:

- ◉ 90% reduction in water usage during cleaning cycles

- ◉ Energy consumption 40% lower than industry average

- ◉ Brand marketed as "world's first carbon-neutral skincare line"

The startup won two sustainability awards and achieved 300% YoY growth, with investors praising their green manufacturing model.