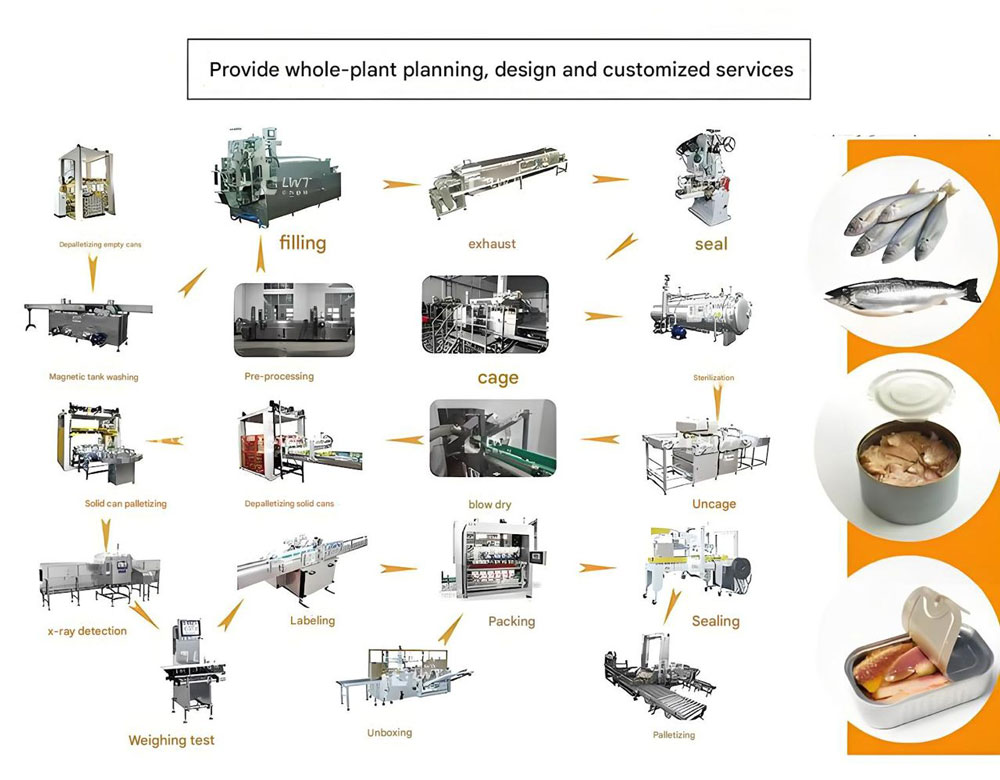

Food processing equipment plays a crucial role in the food production process, designed specifically for handling, processing, and packaging food products. These machines are engineered to enhance production efficiency while ensuring product quality, safety, and consistency. Whether used in large-scale food factories or small-scale production units, this equipment is indispensable for reliable food processing.

For instance, a high-performance meat grinder is a key piece of equipment in meat processing. It efficiently handles large quantities of meat, delivering uniform results. The grinder’s stainless steel exterior weighs 50 kilograms, providing durability and excellent corrosion resistance. Its blades are made from high-carbon steel, ensuring long-lasting sharpness for handling bulk production needs. With a power rating of 2.5 kW, it processes hundreds of kilograms of meat per minute, catering to the demands of high-output production environments.

The meat grinder is equipped with multiple blade configurations, allowing operators to adjust the settings based on the type and texture of the meat, ensuring the desired consistency and mouthfeel of the product. Its built-in safety features prevent overload, ensuring stability during high-intensity operations. The easily detachable components facilitate cleaning and maintenance, adhering to hygiene standards during food production.

This machine is ideal for use in meat processing factories, hotels, and restaurants, capable of processing pork, beef, fish, and other proteins efficiently and hygienically. Maintaining efficient operations and compliance with food safety standards is crucial in the food industry, and this meat grinder is the perfect solution for reliable, large-scale meat processing.

At Yuanlin Food Equipment, we understand the importance of food processing equipment in boosting productivity and ensuring food safety. Our product line includes a variety of food processing machines, from meat grinders to slicers, all designed to help food manufacturers streamline their processes, increase efficiency, and guarantee high-quality food products. Whether for routine production or large-scale processing, our equipment is the dependable choice for any food processing operation.

Standard Function of Meat Grinders

Meat grinders are a fundamental piece of food processing equipment, used widely in meat production facilities and kitchens to efficiently break down raw meats into finely minced or ground products. Standard meat grinders typically come in various sizes, but a common industrial-grade grinder can weigh around 50 kg and process hundreds of kilograms of meat per hour.

Different Models of Meat Grinders

Different models of meat grinders may come with variations in motor power and cutting blade configurations. For instance, a grinder designed for larger production volumes might have a 3 kW motor for higher efficiency, while smaller units may run at 1.5 kW. Blade options range from fine to coarse settings.

Importance of Cutting Blade Sharpness

The sharpness of the cutting blades in a meat grinder plays a vital role in processing speed and product quality. Sharp blades ensure clean cuts, reducing the amount of force needed and minimizing wear on the machine. Regular maintenance ensures the grinder remains effective, prolongs its lifespan, and improves product consistency.

Factors Affecting Meat Grinding Efficiency

Several factors impact the efficiency of meat grinders, including the motor’s power, the sharpness of the blades, and the grind size setting. Proper weight distribution in the meat hopper and regular maintenance of the motor and blades ensure smooth operation.

Meat Type and Grind Size

The type of meat processed—whether fatty or lean—affects the grinding process. For lean meats, a coarser grind may be necessary to avoid clogging, while fattier cuts may require finer settings. Operators should consider these variables to achieve the best results.

Choosing the Right Equipment

Selecting the right meat grinder for food production depends on the scale of operations and the specific product requirements. For smaller kitchens, a 1.5 kW grinder may suffice, while large-scale plants should opt for grinders with more power and advanced features.

Yuanlin Food Equipment Solutions

At Yuanlin Food Equipment, we offer a range of meat grinders and other food processing equipment tailored to meet the needs of both small and large-scale manufacturers. Our products are designed to enhance productivity and provide consistent, high-quality results.

Health Benefits of Food Processing Equipment

Additional Health Benefits

Food processing equipment not only enhances production efficiency but also ensures various health benefits related to food safety and quality:

-

Food Hygiene and Safety: Modern food processing equipment is designed to minimize contamination risks effectively. Many devices feature automatic cleaning systems and antimicrobial surfaces, which help inhibit bacterial growth, ensuring that products meet food safety standards.

-

Nutrient Preservation: Through precise control of temperature and processing conditions, food processing equipment can maximize the retention of nutrients in food products, preventing the loss of vitamins and minerals during processing. This enhances product quality and better meets consumer nutritional needs.

-

Traceability: Advanced food processing equipment often includes data recording and tracking capabilities, enabling the entire process from raw materials to finished products to be traced. This is critical for food recalls and quality management, ensuring consumer safety.

Key Components of Food Processing Equipment

Core Functionality

Food processing equipment plays a vital role in production, primarily through the following components:

-

Cutting Tools and Systems: In devices like meat grinders and slicers, the precision and sharpness of cutting tools are crucial. High-quality blades ensure uniform cuts, reduce material waste, and enhance production efficiency.

-

Temperature Control Systems: For baking and cooking equipment, precise temperature control is essential for maintaining food taste and quality. Advanced temperature control systems can adjust heating levels accurately, ensuring optimal conditions during processing.

-

Conveyor Systems: Automated conveyor belts facilitate continuous food production, minimizing manual intervention. This not only speeds up production but also ensures process consistency, reducing downtime.

Functional Strength and Efficiency

Versatility of Food Processing Equipment

Food processing equipment significantly improves efficiency and offers essential functionalities in everyday operations:

-

Increased Production Efficiency: Automated equipment can process large quantities of food in a short time, significantly reducing manual labor. For instance, automatic meat grinders and slicers can handle hundreds of kilograms of ingredients per hour, greatly decreasing workforce requirements.

-

Multi-functionality: Many modern devices are designed to be multi-functional, enabling the processing of various types of ingredients and products. This adaptability allows manufacturers to adjust quickly to different production lines as needed.

-

Ease of Operation: With advancements in technology, many devices now feature user-friendly interfaces and automated control systems, making complex operations manageable with just a push of a button. This saves operators significant time and effort.

Conclusion

Food processing equipment brings numerous benefits to the food industry, especially in enhancing production efficiency, ensuring food safety, and maintaining product nutritional value. As technology continues to evolve, food processing equipment will advance towards greater automation and intelligence, providing manufacturers with more efficient and reliable solutions.

Food Processing Equipment Repair and Maintenance

1. Regular Inspections

Daily Checks: Ensure basic checks are performed before and after each use of the equipment, such as verifying that all parts are functioning properly and looking for visible signs of wear or damage.

Scheduled Maintenance: Follow the equipment manual's recommendations for scheduled maintenance, such as performing a comprehensive check monthly or quarterly.

2. Cleaning

Pre- and Post-Operation: Clean the equipment immediately after each use to prevent food residue buildup, which helps extend the equipment’s lifespan and ensures food safety.

Use Appropriate Lubricants: Ensure the recommended lubricants are used and follow the correct lubrication procedures.

3. Lubrication

Regular Lubrication: Lubricate moving parts according to the equipment manual to reduce wear and maintain efficient operation.

Use Appropriate Lubricants: Ensure the recommended lubricants are used and follow the correct lubrication procedures.

4. Inspect and Replace Worn Parts

Check for Wear: Regularly inspect components such as belts, blades, and seals for wear and tear to ensure they are in good condition.

Timely Replacement: Replace worn or damaged parts promptly to avoid further damage to the equipment.

5. Calibration and Adjustment

Regular Calibration: Ensure the equipment maintains accuracy throughout its use by performing regular calibrations to ensure optimal performance and product quality.

Adjust Settings: Periodically adjust the equipment settings as needed to ensure it operates at peak efficiency.

6. Operator Training

Operational Training: Provide training for all operators on proper equipment operation and maintenance procedures.

Troubleshooting Training: Equip operators with basic troubleshooting skills to address minor issues promptly.

7. Documentation and Tracking

Maintenance Records: Maintain detailed records of equipment maintenance, including dates and details of inspections, cleaning, lubrication, and part replacements.

Issue Tracking: Document any equipment issues and their resolutions to assist in future diagnostics and repairs.

8. Vendor Collaboration

Professional Support: Contact the equipment supplier or professional repair service providers for assistance with complex maintenance or repair issues.

Must-Read Blogs For Boss

Frequently Asked Questions

All our equipment complies with ISO 22000 food safety management system standards and CE certification. Some equipment is also FDA certified. Please consult our sales team for specific details.

Yes, we offer complete solutions ranging from small-scale to large industrial production. Our team of experts can customize the most suitable solution based on your specific needs.

Our standard warranty is one year, covering parts and labor. We also offer extended warranty services that can be customized to your needs.

Our equipment is made of food-grade stainless steel and designed with easy cleaning in mind. Most equipment comes with a CIP (Clean-in-Place) system to ensure thorough cleaning.

Our equipment covers a wide range of food processing areas, including but not limited to: dairy, meat, fruits and vegetables, grains, beverages, etc. Please check product details or consult our sales team for specific equipment uses.

We provide 24/7 technical support. For simple issues, we can guide you remotely; for complex problems, our technicians can provide on-site service.

We guarantee long-term supply of original spare parts. You can order parts through our online system or by contacting our customer service department. We will ship them as soon as possible.

Our equipment is designed with energy efficiency in mind, with most using variable frequency control technology. We also offer wastewater treatment and energy recovery systems to help customers reduce operating costs and environmental impact.