Do Manufacturers Use The Same Equipment For All Foods

In the grand symphony of food production, manufacturers play the role of skilled conductors orchestrating a harmonious blend of ingredients. However, a question often arises in the minds of culinary enthusiasts: Do manufacturers employ the same equipment for processing all types of foods? Let's embark on a flavorful journey to uncover the secrets behind the scenes.

Section 1: The Versatile Kitchen of Manufacturers

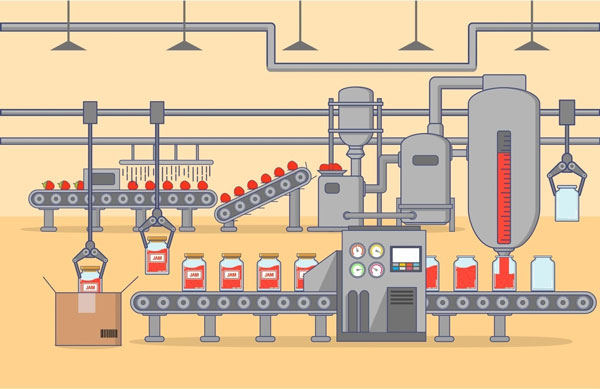

Just as a home chef uses an array of tools to create diverse dishes, food manufacturers operate versatile kitchens equipped with an assortment of machinery. From mixing and blending to cutting and packaging, each piece of equipment is carefully selected to meet the unique requirements of different food products.

Section 2: The Pioneering Art of Processing

Food processing is an art form that demands precision and specialization. For instance, the delicate process of chocolate conching requires equipment tailored to the nuances of cocoa beans, while the production of crisp potato chips necessitates fryers with specific temperature controls. Manufacturers invest in state-of-the-art machinery designed to bring out the best in each ingredient.

Section 3: Tailoring Equipment to Culinary Nuances

Just as a violinist adjusts the strings for different musical compositions, manufacturers tailor their equipment to the culinary nuances of diverse foods. The milling equipment used for flour varies based on the grain, ensuring the precise texture required for baking bread versus crafting pasta.

Section 4: The Role of Material Compatibility

Much like a skilled musician selects the right instrument for a performance, manufacturers consider material compatibility when choosing equipment. Stainless steel may be ideal for machinery involved in acidic food processing, while plastic may be suitable for applications where non-reactivity is paramount.

Section 5: The Heart of Hygiene in Food Manufacturing

Hygiene is the beating heart of food manufacturing. Manufacturers recognize the importance of using equipment designed for easy cleaning and sanitation, especially when transitioning between different food products. Cross-contamination is a conductor's nightmare that diligent cleaning practices and specialized equipment aim to prevent.

Section 6: Embracing Innovation in the Culinary Symphony

Innovation is the driving force in the culinary symphony. Manufacturers continuously explore cutting-edge technologies and equipment that enhance efficiency and quality. This commitment to innovation ensures that each food product, from dairy delights to savory snacks, receives the attention it deserves.

Conclusion: Crafting Culinary Masterpieces

In the enchanting world of food manufacturing, the answer to whether manufacturers use the same equipment for all foods is a nuanced dance of versatility, precision, and innovation. Like masterful conductors leading a symphony, manufacturers employ an array of specialized equipment to craft culinary masterpieces that delight our palates.

Must-Read Blogs For Chain Restaurants Owner

Ready to Get Started?