Meat Sausage Equipment - Chinese Manufacturer, Factory, Supplier

The creation of superlative sausage, that quintessential culinary delight, hinges upon a confluence of factors, not least of which is the deployment of meticulously engineered apparatus. From artisanal charcuteries to large-scale processing facilities, the selection of appropriate implements is paramount to achieving both optimal product quality and efficient throughput. Indeed, the very essence of transforming raw comminuted musculature and adipose tissue into a delectable, cased confection lies in the precision and reliability of Meat Sausage Equipment.

This specialized category encompasses a panoply of devices, each fulfilling a discrete yet vital function in the overall production continuum. Consider, for instance, the imperative of grinding. Robust industrial mincers, often featuring helical screw conveyors and interchangeable die plates, are indispensable for achieving the desired particle size and texture, a critical determinant of the final organoleptic properties. Following this initial comminution, mixing becomes the next crucial stage. Sophisticated industrial blenders, sometimes incorporating vacuum technology to mitigate oxidation and enhance protein extraction, ensure homogenous distribution of seasonings, curing agents, and binders throughout the meat matrix.

The subsequent step, that of stuffing, necessitates the use of specialized sausage fillers. These devices, ranging from manually operated piston stuffers for smaller batches to high-speed hydraulic or rotary vane stuffers for continuous production, precisely meter and encase the meat emulsion into natural or synthetic casings. The consistency and uniformity of this process are critical for both aesthetic appeal and even cooking. Furthermore, for those seeking to produce emulsified sausages, such as frankfurters or mortadella, colloid mills or bowl choppers play an integral role in creating an exceptionally fine and stable emulsion.

In the contemporary globalized marketplace, the sourcing of such sophisticated machinery often leads enterprises to explore international manufacturing hubs. The china Meat Sausage Equipment factory sector has emerged as a significant global purveyor, offering a diverse range of equipment at competitive price points. While due diligence remains paramount in ensuring quality and adherence to international standards, these manufacturers play an increasingly important role in equipping both domestic and international sausage producers.

Investing in high-caliber Meat Sausage Equipment is not merely an expenditure; it represents a strategic imperative for businesses seeking to elevate their product offerings, enhance operational efficiencies, and ultimately, captivate the discerning palates of consumers. The meticulous engineering and robust construction of these specialized implements are fundamental to transforming humble ingredients into culinary masterpieces, ensuring that each and every embutido achieves the pinnacle of savory perfection.

Meat Canned Food Production Line

Meat Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

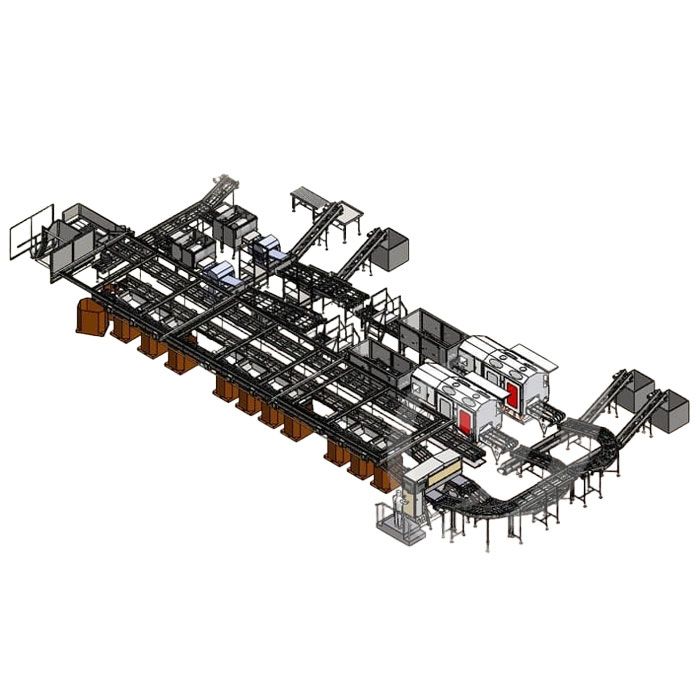

Pet Fish Meat Canning Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Sausage Stuffer Machine

Sausage Stuffer Machine Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Braised Pork Belly Can Production Line

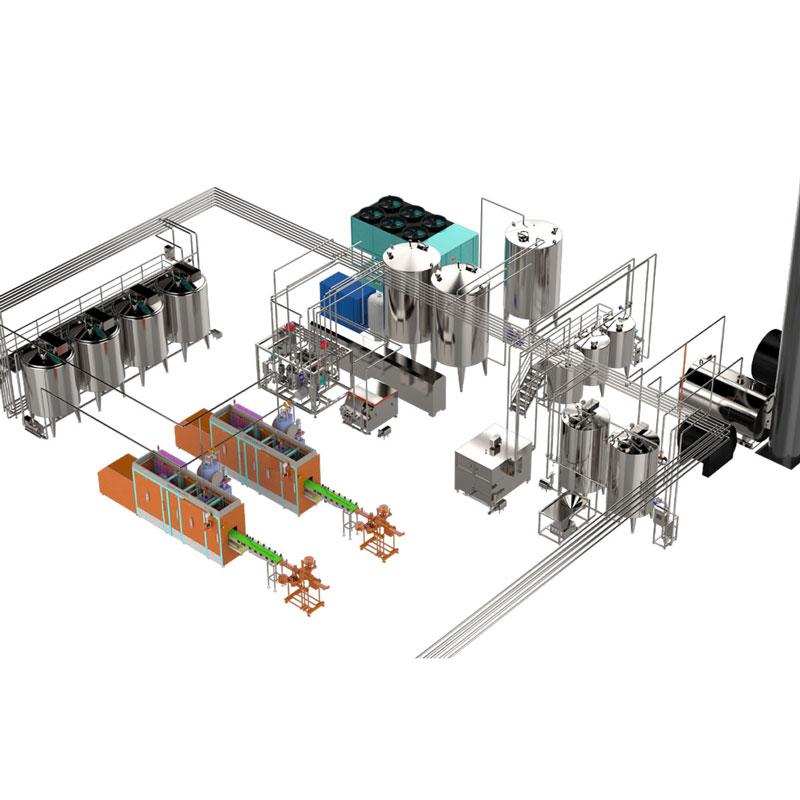

Braised Pork Belly Can Production Line Yogurt Production Line

Yogurt Production Line Commercial Electromagnetic Cooker

Commercial Electromagnetic Cooker Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Bowl Cutter

Bowl Cutter