Benefits of Automated Frying Production Lines in Food Manufacturing

Introduction: Why Modern Food Factories Need Frying Production Lines

In today’s highly competitive food manufacturing industry, automation is no longer a luxury—it is a necessity. Among the various processes that can benefit from advanced automation, frying stands out. Whether for snack foods, meat products, seafood, or ready-to-eat meals, a high-quality frying production line plays a crucial role in achieving consistent product quality, improving operational efficiency, and meeting increasingly stringent food safety standards.

The global demand for fried products remains strong. However, with rising energy costs, labor shortages, and growing scrutiny over food hygiene and sustainability, more businesses are turning to modern, intelligent frying systems to gain a competitive advantage. This article explores everything you need to know about frying production lines—from common industry challenges to key advantages, selection tips, ROI analysis, and future trends.

The Challenges of Traditional Frying Processes

Before the widespread adoption of automated frying systems, many food factories relied on manual or semi-automatic frying methods. These traditional processes are still prevalent in some regions and industries, but they come with significant limitations:

1️⃣ Inconsistent Product Quality

Manual frying often leads to fluctuations in oil temperature and frying time, which directly affect the color, texture, and moisture content of the final product. This inconsistency can lead to high rates of defective products, affecting brand reputation and increasing waste.

2️⃣ High Labor Costs & Inefficiency

Labor-intensive frying processes require continuous supervision and manual handling. This not only raises labor costs but also exposes the operation to human error, fatigue, and inefficiencies.

3️⃣ Excessive Oil Consumption

Without proper oil management systems, traditional fryers suffer from high oil turnover rates. Frequent oil changes increase operating costs and create more waste, making the process less sustainable.

4️⃣ Food Safety & Hygiene Risks

Manual processes make it harder to maintain strict hygiene standards. Frequent human contact, open oil tanks, and poor cleaning access all increase the risk of contamination and accidents.

5️⃣ Energy Waste & Environmental Concerns

Old-fashioned fryers are often energy-inefficient, with poor insulation and outdated heating systems that waste both energy and money.

Why Choose an Automated Frying Production Line?

Modern frying production lines are designed to address these challenges head-on. Investing in an automated frying solution can transform your production capacity, operational efficiency, and product quality.

✅ Consistency & Precision

Advanced frying lines use intelligent temperature controls and programmable settings to ensure precise frying times and temperatures. This guarantees uniform product appearance, texture, and taste—batch after batch.

✅ Oil Management & Energy Efficiency

State-of-the-art oil filtration systems continuously clean the frying oil, extending its lifespan and reducing consumption by up to 50%. Modern heating elements and insulation also minimize energy usage, contributing to a greener operation.

✅ Enhanced Food Safety & Hygiene

Closed-loop designs, CIP (clean-in-place) systems, and stainless-steel construction ensure the highest hygiene standards. Automated lines reduce human contact, lowering the risk of contamination.

✅ Reduced Labor Costs

Automated systems require minimal manual intervention. Operators can oversee multiple lines simultaneously through user-friendly control panels, drastically reducing labor dependency.

✅ Scalability & Versatility

Modern frying lines can handle a wide range of products:

Potato chips, French fries

Fried snacks (nuts, crackers)

Breaded seafood & meat products

Pre-cooked meals

Tempura or coated vegetables

Switching between different products is quick and efficient, allowing manufacturers to adapt to market demands.

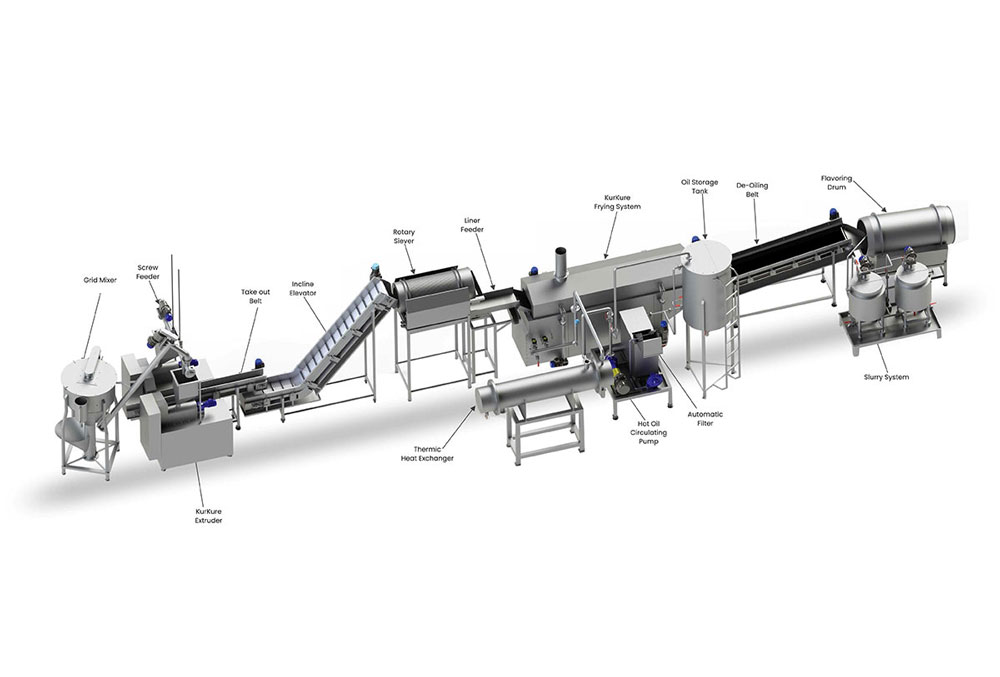

Key Components of a Frying Production Line

A typical frying production line consists of the following components:

➤ Feeding System

Ensures consistent and controlled input of raw or pre-processed materials into the fryer.

➤ Continuous Frying Machine

The heart of the system, featuring precise temperature control, adjustable frying zones, and conveyor speeds tailored to specific products.

➤ Oil Filtration & Circulation System

Continuously filters out food particles, maintains oil quality, and improves heat transfer efficiency.

➤ De-oiling System

Removes excess surface oil through shaking or centrifugal systems, contributing to better product texture and reduced oil content.

➤ Cooling & Conveying System

Rapidly cools products post-frying to preserve texture and prevent overcooking.

➤ Control Panel / PLC System

Allows operators to manage and monitor every stage of the frying process through an intuitive interface.

How to Choose the Right Frying Production Line

Selecting the most suitable frying production line for your business depends on several factors. Here’s a detailed guide to making the right decision:

1️⃣ Product Type & Specifications

Different products require different frying technologies (continuous frying, batch frying, deep frying, shallow frying). Consider the size, shape, and composition of your materials.

2️⃣ Production Capacity

Evaluate your current and future output needs. Equipment should match your volume targets while allowing flexibility for growth.

3️⃣ Energy & Oil Efficiency

Look for systems designed with heat recovery, oil filtration, and insulation technologies to reduce operating costs over time.

4️⃣ Hygiene & Maintenance

Opt for designs that facilitate easy cleaning, maintenance access, and compliance with international food safety standards (CE, FDA, HACCP).

5️⃣ Automation & Integration

Ensure the system can integrate seamlessly with upstream and downstream equipment (coating lines, freezing lines, packaging lines) and digital factory systems (SCADA, MES).

6️⃣ After-Sales Support

Reliable after-sales service, spare parts availability, and technical training are crucial for long-term operational stability.

ROI Analysis: Investing in a Frying Production Line

Many food manufacturers view automation as a significant upfront expense. However, a well-selected frying production line offers tangible, measurable returns on investment:

💡 Reduced Operating Costs

Up to 50% savings on oil consumption

Significant reductions in energy usage (heat recovery systems)

Lower labor costs through automation

💡 Improved Product Quality

Higher yield of saleable products

Consistent quality strengthens brand reputation

Reduced customer complaints and returns

💡 Enhanced Food Safety & Compliance

Meet global food safety certifications with ease

Reduced contamination risks lead to fewer recalls

💡 Sustainability & Waste Reduction

Less oil waste, lower carbon emissions

Better utilization of raw materials

Payback Period Example:

Depending on production scale, many factories achieve full ROI within 2-4 years through operational savings alone.

Case Studies: Success Stories from the Industry

✅ Snack Foods Manufacturer (USA)

Transitioned from semi-automatic fryers to a continuous frying production line. Result:

30% reduction in oil consumption

20% increase in output capacity

Achieved BRC and FDA certifications within 12 months

✅ Frozen Foods Producer (Europe)

Upgraded to an integrated frying and freezing line for coated seafood products. Result:

Consistent quality suitable for export to high-standard markets

Streamlined production reduced labor costs by 25%

Enhanced energy efficiency through heat recovery systems

Future Trends in Frying Technology

The food manufacturing industry continues to evolve, and so do frying technologies. Key trends shaping the future include:

🌍 Sustainability Focus

Manufacturers are seeking equipment that reduces oil waste, energy consumption, and carbon footprints. Advanced filtration, heat recovery, and eco-friendly materials will be key.

🤖 Intelligent Automation

Integration with Industry 4.0 platforms, AI-powered quality monitoring, and predictive maintenance are becoming standard.

🥑 Health-Conscious Frying

Technology advancements aim to minimize oil absorption and promote healthier fried products. Air-frying hybrids and vacuum frying systems are gaining attention.

🔗 Digital Integration

Frying lines are increasingly part of smart factory ecosystems, with real-time data collection enhancing production oversight and traceability.

Conclusion: Partnering with the Right Supplier

Choosing the right frying production line is not just about equipment—it’s about selecting a partner who understands your business, your products, and your goals. A professional, experienced manufacturer can provide tailored solutions, reliable support, and long-term value that go far beyond the machine itself.

If your business is ready to improve productivity, enhance product quality, and secure a competitive edge in the market, investing in a high-quality frying production line is the logical next step.

Contact us today to explore customized solutions for your specific frying production needs.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?