Poultry Processing Line: Automation Upgrade to Build High-Efficiency, Energy-Saving Plants

As global consumers demand higher food safety, product consistency, and supply chain reliability, the poultry slaughtering and processing industry is undergoing unprecedented transformation. From live bird reception through slaughter, evisceration, chilling, portioning, and packaging, every stage’s automation and standardization are crucial—not only for efficiency and cost control but also for securing a competitive market position and sustainable growth.

This article systematically explores the current challenges in poultry processing, the core value of automated slaughtering and processing lines, and the industry trends and ROI analysis to help enterprises clearly define their future upgrade paths.

1️⃣ Industry Challenges: The Limitations of Traditional Poultry Processing

Heavy Labor Dependency and Management Complexity

Traditional poultry processing relies heavily on manual labor, resulting in inconsistent standards, unstable efficiency, and poor process control. Rising labor costs and workforce shortages create additional pressure, threatening production continuity and stability.

Difficulties in Food Safety Compliance and Standardization

Manual handling across multiple steps increases cross-contamination risk, hygiene blind spots, and traceability gaps. Traditional slaughter methods struggle to meet stringent domestic and international food safety regulations and retailer requirements.

Unclear Cost Structures and Inefficient Resource Use

High labor ratios and low efficiency lead to underutilized capacity and excessive waste. Without refined data management, companies struggle with accurate cost accounting and profitability assessments, impacting long-term competitiveness.

Low Product Added Value and Limited Brand Development

Crude portioning cannot support diversified, high-spec products demanded by modern retail, foodservice, and ready-to-eat markets, restricting enterprises’ ability to enter premium segments and build brand equity.

2️⃣ Comprehensive Automated Poultry Slaughtering and Deep Processing Lines: Addressing Core Industry Needs

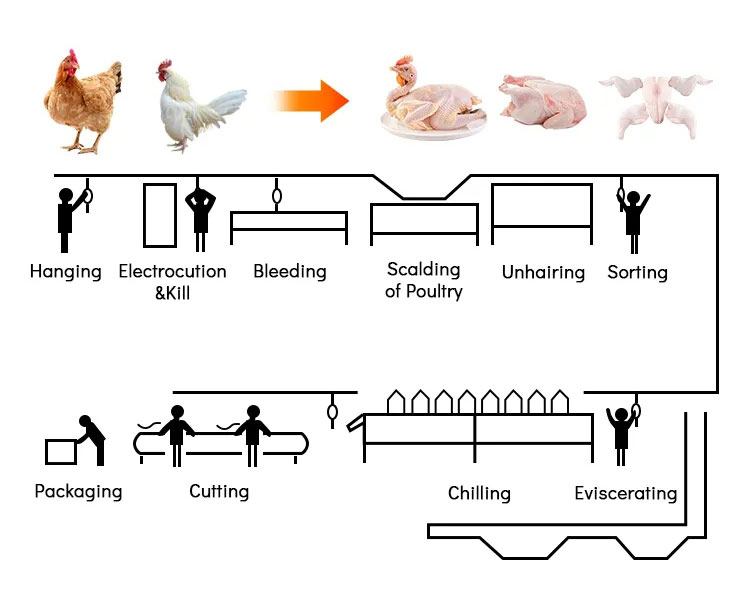

Our automated production lines cover every critical step for chicken, duck, goose, and other poultry: from live bird reception, hanging, stunning, slaughtering, bleeding, scalding, defeathering, evisceration, chilling, portioning, to packaging. This enables processors to achieve standardized, scalable, and intelligent operations.

Complete Process Overview

| Process Stage | Equipment / Technology | Core Benefits |

|---|---|---|

| Live Bird Reception | Automated Reception System | Rapid, low-stress bird handling preserving meat quality |

| Hanging | Automatic Hanging Devices | Increased efficiency, reduced labor, standardized operation |

| Stunning & Slaughtering | Gas/Electric Stunning, Automated Slaughter | Humane treatment, precise slaughter, minimized quality loss |

| Bleeding & Scalding | Bleeding Lines, Scalding Tanks | Complete blood removal, improved product color and quality |

| Defeathering | Defeathering Machines | High removal rate, minimized damage, consistent appearance |

| Evisceration | Automatic Evisceration Lines | Reduced contamination, improved hygiene, higher yield |

| Chilling & Portioning | Chilling Systems, Cutting Lines | Temperature control ensures texture and color; multi-spec product capability |

| By-product Sorting | Offal and Feet Sorting Lines | Increased by-product value and raw material utilization |

| Packaging & Freezing | Vacuum Packaging, Blast Freezing | Extended shelf life, improved logistics safety |

3️⃣ Key Technological Advantages of Modern Poultry Processing

End-to-End Automation

Seamless equipment integration reduces manual intervention, enhances throughput, lowers contamination risk, and ensures stable line operation with consistent product quality.

Food-Grade Hygiene Standards

All equipment is built with stainless steel and hygienic designs compliant with HACCP, BRC, and other international food safety certifications. Easy cleaning and maintenance safeguard processing environments.

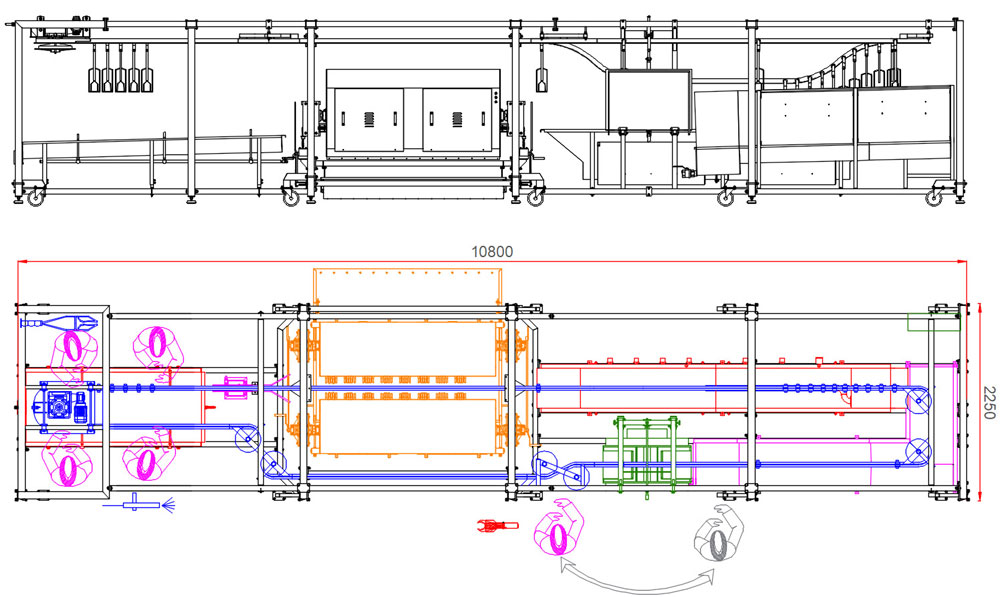

Modular and Flexible Layout

Scalable configurations accommodate capacities from 5,000 to 12,000 birds per hour, meeting a variety of plant sizes and production targets, adaptable for future expansions.

Data-Driven Management and Traceability

Comprehensive data collection supports production tracking, energy monitoring, and efficiency analysis, enabling digital factory transformation and precision management.

Enhanced By-product Utilization

Automated sorting and separate handling of feet, offal, and other by-products maximize raw material value, diversifying product portfolios and increasing profitability.

4️⃣ Investment & ROI Analysis: Clear Cost Control and Profitability

The benefits of automation compared to traditional manual methods are evident:

| KPI | Traditional Manual Operation | Automated Production Line |

|---|---|---|

| Labor Requirements | High, difficult to manage | Over 50% labor cost reduction |

| Food Safety Compliance | High risk, many blind spots | Standardized, traceable |

| Product Consistency | Poor, frequent complaints | Precise weight, uniform specs |

| Cost Transparency | Low, high wastage | 3-5% reduced loss, data-controlled |

| By-product Utilization | Low, much waste | Sorted and valorized |

| Brand Value & Market Access | Limited | Access to premium retail, export, and ready-meal markets |

For example, a facility processing 10 million birds annually can recover equipment investments within 1–2 years through labor savings and yield improvements alone, with ongoing benefits in cost reduction and profit growth.

5️⃣ Market Trends and Future Outlook

Increasing Demand for Standardization

Retail chains, foodservice operators, and ready-meal manufacturers increasingly demand standardized, hygienic poultry raw materials, pushing processors to upgrade lines to ensure consistent quality.

Strengthening Food Safety Regulations

Global food safety frameworks (HACCP, BRC, HALAL) become baseline requirements. Traditional manual operations cannot meet these rising standards.

Disappearance of Labor Advantages

Rising labor costs and shrinking labor pools make manual processing unsustainable. Automation is the clear path forward for competitive survival.

Digital Factory Transformation

Data-driven management, intelligent traceability, and energy optimization become industry norms, boosting operational efficiency and market competitiveness.

6️⃣ Conclusion: Automation is the Inevitable Future for Poultry Processors

Investing in automated poultry slaughtering and deep processing lines is a strategic transformation—beyond equipment purchase—to establish a modern, scalable, and digital production system. This transformation improves operational efficiency, food safety compliance, cost structures, and brand competitiveness, securing sustainable growth and future-proofing businesses.

As a dedicated manufacturer of poultry processing equipment, we offer reliable, proven technology, rich industry expertise, and comprehensive technical support to help you build a modern poultry processing plant and seize the competitive edge.

📩 Contact us today to request a tailored production line solution or to schedule a visit to our demonstration plant and experience the benefits of intelligent poultry processing firsthand.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?