Customized Solutions for Canned Sardine Production Lines

Unlocking Efficiency, Hygiene, and Market Agility Through Tailored Machinery

Understanding the Importance of Customization in Canned Sardine Production

In a market where consumer expectations and global standards evolve rapidly, canned sardine producers cannot afford to rely on generic equipment. Customization is not a luxury—it's a strategic necessity. From region-specific regulations to product texture preferences, every element of production must reflect the unique demands of the brand and market. Tailored solutions ensure seamless integration of machinery, optimized resource use, and consistent product quality, giving processors a definitive edge.

Why One-Size-Fits-All Approaches Fall Short in Modern Seafood Processing

Generic processing lines often fail to address operational realities like factory layout constraints, raw material variability, and packaging diversity. These limitations result in frequent downtime, inconsistent product quality, and reduced throughput. Customized systems, by contrast, are engineered to adapt to specific production goals, workforce capabilities, and environmental conditions—resulting in smoother operations and higher profit margins.

Key Components of a Canned Sardine Production Line

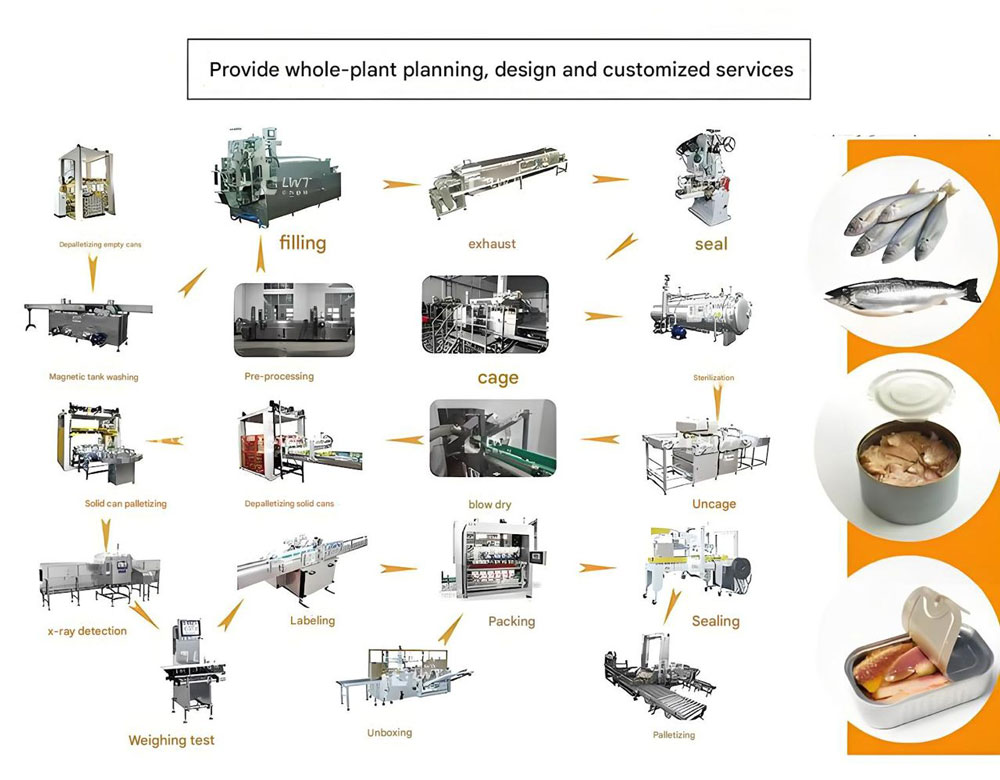

A robust Sardine Canning Line integrates several interdependent systems:

Receiving & Sorting Units

De-scaling, Cleaning, and Gutting Machines

Cooking Equipment (Steamers/Retorts)

Brine/Oil Injection Systems

Filling and Sealing Machines

Sterilizers and Cooling Tunnels

Labeling and Cartoning Systems

Each element plays a vital role in preserving the integrity, flavor, and safety of the final product.

The Role of Automation in Enhancing Efficiency

Automated systems reduce manual handling, limit human error, and drastically improve production speed. From robotic fish loaders to smart sealing units with real-time diagnostics, automation enhances throughput while maintaining strict adherence to hygiene and food safety protocols. Labor costs drop, productivity rises, and consistency becomes the norm.

Designing a Tailored Production Layout

Every facility has unique spatial constraints. A customized layout maximizes available floor area by aligning equipment to the natural flow of materials. Strategic zoning for raw intake, processing, and packaging minimizes cross-contamination risks and accelerates transition times between batches or product types.

Selecting the Right Raw Material Handling Equipment

Sardine freshness begins with efficient unloading and transfer systems. Specialized conveyors with low-friction surfaces, insulated holding tanks, and gentle hoists ensure minimal bruising and spoilage during intake. Custom handling equipment also simplifies cleaning routines and enhances biosecurity.

Precision Cleaning and Gutting Systems

Modern gutting systems use high-pressure water jets, precision blades, and vacuum extraction to clean fish quickly and hygienically. Machine customization allows processors to accommodate sardines of varying sizes and conditions while ensuring compliance with sanitation benchmarks.

Cooking and Sterilization: Balancing Flavor and Safety

Cooking is both a science and an art. Customized retort systems offer programmable cycles for temperature, pressure, and duration—enabling processors to achieve perfect doneness without compromising nutritional value. Innovations such as horizontal rotary retorts and heat recovery modules further optimize the process.

Filling and Sealing: Maintaining Product Integrity

Accurate filling ensures that each can meets weight specifications and contains consistent fish-to-liquid ratios. Tailored sealing equipment adapts to diverse can formats and lid types, preventing vacuum failures and leakages while supporting multi-product flexibility.

Brine and Oil Injection: Consistency in Every Can

Brine and oil not only preserve sardines but also define taste. Injection systems must deliver exact ratios under controlled temperatures to prevent separation or microbial growth. Custom units support viscosity variations and inline mixing to maintain taste uniformity.

Labeling and Coding: Compliance and Brand Identity

Custom labeling machines allow producers to switch between SKUs quickly while maintaining print clarity and alignment. Integrated inkjet or laser coders ensure traceability with batch numbers and expiry dates that comply with EU, FDA, and other global standards.

Quality Control Measures in Custom Production Lines

Real-time sensors track weight, seal integrity, and metal contaminants with pinpoint accuracy. Vision inspection systems detect can defects, while inline checkweighers eliminate under- or over-filled products. Customized QC integrations ensure every can meets defined specifications before leaving the line.

Sustainability in Custom Seafood Processing Equipment

Eco-conscious machinery designs reduce energy, water, and steam consumption. Examples include closed-loop water filtration systems, low-emission burners, and variable-frequency drives (VFDs). These innovations lower operating costs and enhance environmental stewardship.

Scalability: Preparing for Future Growth

Modular production lines offer room to expand without reconfiguring the entire facility. Adding a second filler or integrating an automated palletizer becomes seamless. This flexibility ensures your infrastructure evolves in step with market demand.

The Impact of Hygienic Design on Food Safety

Stainless steel frames, sloped surfaces for drainage, and tool-free access panels reduce microbial harborage points. Custom-built units simplify cleaning-in-place (CIP) operations, ensuring routine sanitation doesn't compromise uptime.

Custom Conveyor Systems for Smooth Material Flow

Well-engineered conveyors prevent product jamming and damage. Whether using gravity-fed chutes, magnetic lifts, or belt systems, customized conveyors are designed for your specific throughput rates and sardine sizes, minimizing bottlenecks.

Waste Management Solutions for Eco-Friendly Operations

Fish heads, bones, and offcuts can be transformed into fishmeal or oil. Integrated waste sorting and grinding systems reduce landfill use while generating revenue from byproducts. Custom solutions streamline this process without disrupting the main production line.

Training and Support: Ensuring Seamless Implementation

Advanced equipment demands skilled operators. Comprehensive training—ranging from machine handling to maintenance protocols—ensures a swift learning curve. On-site support and digital manuals enhance long-term productivity.

Cost-Benefit Analysis of Custom vs. Standard Equipment

Although initial costs may be higher, customized systems deliver lower lifetime operational costs. Benefits include less waste, higher output, energy savings, and fewer maintenance disruptions. ROI often materializes within 1–2 years for high-volume processors.

Case Study: A Custom Solution for High-Volume Exporters

A leading Mediterranean exporter revamped its sardine line with customized high-speed fillers, automated labelers, and energy-efficient retorts. Result: 40% production increase, 20% energy savings, and faster compliance with EU traceability standards.

Addressing Regulatory Challenges in International Markets

Export-ready production lines must meet diverse food safety codes. Custom machinery can be configured with interchangeable parts, allergen separation units, and traceability software to comply with EU, FDA, BRC, and HACCP regulations simultaneously.

Innovations in Can Sterilization Technology

Next-generation sterilizers use overpressure cycles and water-spray cooling for nutrient retention and precise temperature control. IoT-enabled systems allow remote diagnostics and reduce overprocessing risks.

Adapting to Seasonal Variations in Sardine Supply

Custom cold storage units and buffer tanks smooth out supply gaps. Quick-adjust sorting lines and flexible processing schedules allow processors to adapt to catch volume fluctuations without halting operations.

Energy-Efficient Production: Cutting Costs Without Sacrificing Quality

Heat exchangers, LED lighting, and variable-speed motors contribute to significant energy reductions. Sensors automatically adjust water and steam flow based on product load—preserving quality while optimizing cost.

The Role of Data Analytics in Process Optimization

Machine-learning algorithms analyze performance trends, forecast maintenance needs, and detect inefficiencies. Customized dashboards offer real-time visibility, empowering supervisors to make data-driven decisions instantly.

Overcoming Common Bottlenecks in Canned Sardine Lines

Downtime at the labeling or filling stage often stems from misaligned machinery or clunky transitions. Custom integration solutions—like synchronized drive systems and anti-jam feeders—resolve these chokepoints efficiently.

Custom Packaging Solutions: Standing Out in Competitive Markets

Unique can shapes, embossed lids, and biodegradable packaging materials enhance brand visibility. Custom machinery supports fast format changes to switch between retail, bulk, or private label SKUs.

Food Safety Audits: Ensuring Compliance in Custom Lines

Third-party auditors demand traceable, sanitized, and documented operations. Custom lines integrate digital logs, real-time alerts, and self-cleaning functions to pass inspections with ease.

Collaborating with Engineers for Bespoke Solutions

Effective collaboration begins with detailed briefs—capacity goals, product specs, compliance targets. Continuous feedback during prototyping ensures the final system mirrors operational realities and brand goals.

Future-Proofing Your Production Line

Investing in adaptable infrastructure is key to long-term success. AI-driven systems that auto-calibrate based on fish quality, predictive maintenance alerts, and scalable designs ensure readiness for future innovations.

Conclusion: The Competitive Edge of Customization

In the sardine canning industry, precision and flexibility define success. Customized production lines not only streamline operations but elevate product quality, regulatory compliance, and brand reputation. Tailored solutions aren't just upgrades—they're long-term strategic advantages.

Call to Action: Partnering with Experts for Your Custom Needs

Maximize the efficiency and quality of your canned sardine production with customized, future-ready systems. Collaborate with industry-leading engineers and technical specialists to build a production line that aligns with your vision, volume, and market.

Frequently Asked Questions (FAQs)

Q1: How long does it take to install a customized sardine production line?

A: Depending on complexity, installation typically ranges from 2 to 6 months, including layout planning, manufacturing, installation, and testing.

Q2: Can custom equipment be retrofitted into an existing line?

A: Yes, many components such as fillers, conveyors, and retorts can be tailored to integrate with legacy systems, minimizing downtime and capital costs.

Q3: Are customized systems compliant with international food safety standards?

A: Absolutely. Equipment can be designed to meet or exceed requirements from HACCP, FDA, EU, BRC, and ISO certifications.

Q4: What kind of maintenance do custom lines require?

A: Maintenance is typically lower than standard equipment due to precision engineering. Many systems include predictive alerts and digital logs for proactive upkeep.

Q5: How scalable are custom solutions?

A: Most custom lines are modular and designed to scale. Components can be added or upgraded as production demand increases.

Q6: Is operator training provided?

A: Yes, comprehensive training is offered, including manuals, video tutorials, and on-site sessions for equipment operation and troubleshooting.

Q7: Can custom equipment help reduce environmental impact?

A: Yes. Innovations such as water recycling systems, energy-efficient motors, and waste-to-value solutions significantly reduce the carbon footprint.

Q8: How do I start customizing a sardine production line for my facility?

A: Begin with a detailed consultation to assess your processing needs, facility layout, regulatory requirements, and desired output. An engineering partner will then develop a tailored proposal.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?