I. Control System and Operation Interface

This packaging machine uses imported PLC for precise control, ensuring the stability and reliability of the equipment's operation, and providing a solid foundation for the entire packaging process. It is equipped with a large-sized color touch screen, which is intuitive and easy to operate, making it easy to complete a series of operations such as parameter settings and function adjustments, effectively improving the efficiency of operation.

II. Power Drive and Maintenance

With the help of servo drive technology, precise cutting is achieved, which not only improves the accuracy of packaging but also greatly reduces the difficulty and cost of maintenance, making daily maintenance of the equipment more worry-free and labor-saving.

III. Tracking and Positioning Functions

The application of imported color mark photoelectric switch, combined with bi-directional tracking technology, can accurately capture the color marks on the packaging material, ensuring the precise alignment of the packaging pattern, making the appearance of the packaging product more beautiful and neat. At the same time, the equipment has a positioning stop function, which can effectively avoid the problem of film scorching caused by abnormal shutdown, reducing material waste and the risk of equipment failure.

IV. Temperature Control System

Using an intelligent temperature controller, combined with PID control technology, can precisely control the sealing temperature, ensuring the stability and accuracy of the temperature. This not only improves the quality of the seal but also extends the service life of the equipment, reducing packaging problems caused by temperature fluctuations.

V. Safety and Protective Devices

The cross-sealing part is equipped with a cutting protection cover and a misalignment prevention device, which not only ensures the safety of the operators but also effectively prevents packaging quality problems caused by misalignment, improving the overall quality of the packaging.

VI. Longitudinal Sealing Technology and Defective Rate Control

The application of direct heating longitudinal sealing technology not only improves the service life of the equipment but also effectively reduces the quality problems caused by film scorching during shutdown, greatly reducing the defective rate, improving production efficiency and economic benefits.

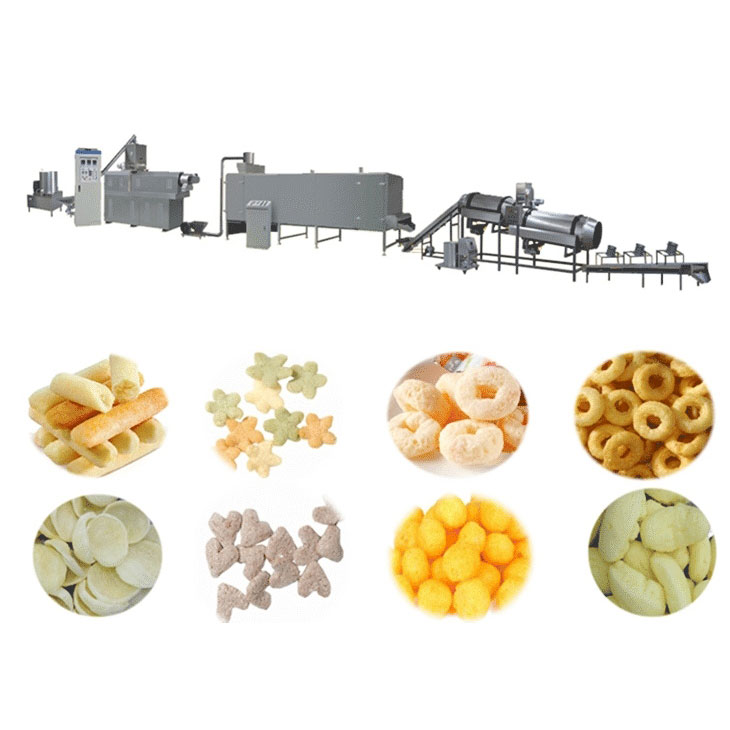

VII. Product Types and Application Range

Our company mainly operates a variety of packaging machines, including pillow-type rotary packaging machines, pillow-type reciprocating packaging machines, and transverse feeding machines, which can provide customers with comprehensive packaging solutions. Our products are widely used for various packaging needs, such as popsicles and other cold drinks, pastry packaging machines made of stainless steel, double servo and triple servo packaging machines, reciprocating packaging machines, heat shrink packaging machines and heat shrink ovens, transverse packaging machines, slicing packaging machines, bottom feeding packaging machines, etc. These devices can be widely used for packaging solid items such as bagged or tubed instant noodles, vermicelli and rice noodles, and other convenience foods, irregularly shaped round or square biscuits, snow rice cakes, egg yolk pies, artemisia cakes, chocolate, cup yogurt, ice cream, wafers, paper-wrapped noodles, steamed bread slices, disinfected tableware, disposable disinfected tableware, soap, medicine boxes, medicine boards, medicines, mooncakes, pastries, bread, frozen food, quick-frozen food, etc., covering multiple industries such as food, dairy, cold drinks, hardware, daily chemicals, and pharmaceuticals, meeting the diverse packaging needs of different customers.

Must-read blogs for bosses