Specific Food Processing: How Equipment Meets Specific Food Production Needs

Introduction

The food processing industry plays a crucial role in ensuring that food products are safe, nutritious, and appealing to consumers. With the increasing demand for diverse food products, the need for specialized equipment that caters to specific food production needs has become paramount. In this article, we will delve into how various types of food processing equipment meet these needs, enhancing efficiency, quality, and sustainability in food production.

Understanding Food Processing Needs

Food processing involves converting raw ingredients into consumable products through various methods such as cooking, preserving, and packaging. Different food products require specific processing techniques and equipment. Understanding these unique needs is essential for manufacturers to optimize their production lines.

1. Equipment for Meat Processing

1.1 Types of Meat Processing Equipment

- Meat Grinders: Essential for grinding various types of meat, enabling the production of sausages, burgers, and minced meat products.

- Slicers: Used for cutting meat into desired sizes for deli meats and other products.

Marinators: Equipment that ensures even marination, enhancing flavor and tenderness.

1.2 Meeting Specific Needs

The meat industry faces challenges such as ensuring food safety, maintaining product quality, and meeting regulatory standards. Equipment like vacuum sealers helps extend shelf life, while temperature-controlled environments ensure safe processing. For instance, a meat grinder designed for high volume can handle the production needs of a large meat processing plant, improving efficiency and consistency.

2. Equipment for Dairy Processing

2.1 Types of Dairy Processing Equipment

- Pasteurizers: Essential for killing harmful bacteria without compromising nutritional quality.

- Homogenizers: Used to create a uniform product by breaking down fat molecules.

Cheese Machines: Specialized equipment for curd cutting, pressing, and molding.

2.2 Meeting Specific Needs

Dairy processors require equipment that maintains hygiene and quality. Automated systems minimize human contact, reducing contamination risks. Additionally, advanced monitoring systems can track temperature and pressure during processing, ensuring compliance with safety standards. For example, a continuous pasteurization system allows for efficient processing of milk, enhancing productivity.

3. Equipment for Bakery Production

3.1 Types of Bakery Equipment

- Mixers: Industrial mixers ensure uniform mixing of ingredients for dough consistency.

- Ovens: Specialized ovens provide the ideal baking conditions for various products.

Proofers: These create the perfect environment for dough to rise.

3.2 Meeting Specific Needs

Bakery production requires precise control over mixing and baking times. High-capacity mixers enable the production of large batches while maintaining consistency. Ovens equipped with steam injection systems can enhance crust quality in bread, meeting consumer demands for artisanal products. Moreover, automated proofers ensure uniform rising, critical for product quality.

4. Equipment for Beverage Processing

4.1 Types of Beverage Processing Equipment

- Brewing Systems: Used for brewing beer and other fermented beverages.

- Juicers: Specialized equipment for extracting juice from fruits and vegetables.

Filling Machines: Ensures accurate and hygienic filling of containers.

4.2 Meeting Specific Needs

The beverage industry is driven by trends toward health and wellness. Equipment like cold-press juicers retains more nutrients and flavors, catering to consumer preferences for fresh products. Automated filling machines ensure consistency and reduce waste, critical for large-scale production. Additionally, quality control systems monitor the fermentation process, ensuring product quality.

5. Equipment for Vegetable and Fruit Processing

5.1 Types of Vegetable and Fruit Processing Equipment

- Cutting Machines: For chopping, dicing, and slicing fruits and vegetables.

- Blanchers: Used to inactivate enzymes and preserve color and texture.

Packaging Equipment: For vacuum sealing and preserving freshness.

5.2 Meeting Specific Needs

Vegetable and fruit processors must maintain freshness and quality while maximizing shelf life. Blanching equipment preserves color and nutrients, ensuring that products meet consumer expectations. Packaging machines that use modified atmosphere technology can extend shelf life without compromising quality. For instance, a high-capacity cutting machine can handle large volumes, ensuring efficient processing during peak seasons.

6. Equipment for Snack Food Production

6.1 Types of Snack Food Processing Equipment

- Fryers: For producing chips and other fried snacks.

- Extruders: Used to create puffed snacks and cereals.

- Coaters: For adding flavorings and coatings to snack products.

6.2 Meeting Specific Needs

Snack food production requires equipment that enhances flavor while maintaining texture. Advanced frying systems with temperature controls ensure consistent frying, reducing oil absorption. Extrusion technology allows for the creation of diverse shapes and textures, meeting consumer demands for innovation. Moreover, automated coating systems can apply flavorings uniformly, enhancing product appeal.

7. Sustainability and Efficiency in Food Processing

With increasing consumer awareness of sustainability, food processing equipment is evolving to meet these demands. Modern machines are designed for energy efficiency, waste reduction, and resource optimization.

- Energy-efficient Equipment: Many manufacturers are investing in technology that reduces energy consumption during processing.

- Waste Minimization: Equipment that optimizes raw material usage minimizes waste, contributing to a more sustainable food supply chain.

- Water Recycling Systems: These systems help reduce water usage, crucial in regions facing water scarcity.

Conclusion

The food processing industry is dynamic and continuously evolving to meet specific production needs. Specialized equipment plays a vital role in enhancing efficiency, quality, and sustainability. By understanding the unique requirements of various food sectors, manufacturers can invest in the right technologies, ensuring that they meet consumer demands while adhering to safety and quality standards.

As the industry continues to innovate, staying abreast of the latest equipment trends will be essential for food processors aiming to thrive in a competitive market.

Must-Read Blogs For Chain Restaurants Owner

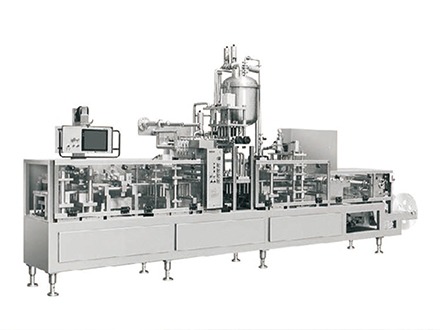

Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line

Ready to Get Started?