Commercial Pasta Machine - Chinese Manufacturer, Factory, Supplier

Introduce the importance of a Commercial Pasta Machine in the pasta-making process. Explain how it helps restaurants and food factories improve production efficiency, ensure consistent pasta quality, and save time and labor in high-volume production. Highlight the irreplaceable role of the commercial pasta machine in large-scale pasta production.

Why Choose a Commercial Pasta Machine?

Increase Production Efficiency

A commercial pasta machine significantly boosts the speed of pasta production, reducing manual labor and quickly producing large quantities of pasta, making it ideal for busy restaurants and food factories. Compared to manual production, using a commercial pasta machine can shorten production cycles.Consistency and High Quality

The commercial pasta machine ensures the uniformity of each batch of dough and consistency in pasta thickness and texture. This eliminates the issues of uneven pasta produced by manual methods, enhancing product standardization and control.Versatility to Meet Various Needs

Not only suitable for traditional pasta, but it can also make wide noodles, dumpling wrappers, handmade pasta, and more. Its versatility meets the diverse needs of restaurants and food factories.Labor Cost Savings

By reducing the need for manual labor, the commercial pasta machine lowers labor costs and enhances efficiency, which ultimately boosts profits.

Key Features

Powerful Motor and High Output

The commercial pasta machine comes equipped with a high-power motor, enabling it to produce large quantities of pasta in a short amount of time, suitable for high-volume production. For example, it can produce hundreds of kilograms of pasta per hour, meeting the demands of large restaurants or food factories.Stainless Steel Construction

Most commercial pasta machines are made from durable stainless steel, which is corrosion-resistant, easy to clean, and ensures long-lasting durability.Multiple Pasta Options

The machine offers multiple molds and thickness adjustments, catering to the production of various types of pasta. With adjustable molds, you can easily create spaghetti, lasagna, wide noodles, and dumpling wrappers.Automation and Smart Control

Equipped with an intuitive control panel, the commercial pasta machine simplifies the operation process, reducing manual intervention and ensuring consistent and stable production.Easy to Clean and Maintain

The machine is designed for easy disassembly and cleaning, ensuring regular maintenance is straightforward, prolonging the machine’s lifespan and minimizing downtime.

Suitable Applications

Restaurants & Pasta Shops

A commercial pasta machine is ideal for medium to large restaurants and pasta shops that need to produce large quantities of pasta, dumpling wrappers, or handmade pasta efficiently during peak hours.Food Factories

For large-scale pasta production, a commercial pasta machine is an essential part of the production line, improving productivity and ensuring consistent product quality.Hotels & Catering Services

Hotels and banquet services that require large-scale pasta production for events can benefit from this machine, as it quickly makes various pasta types in bulk.Supermarkets & Wholesalers

Supermarkets and wholesalers can use a commercial pasta machine to provide fresh, custom-made pasta for customers, meeting the demand for freshly prepared pasta products.

Factors to Consider When Choosing a Commercial Pasta Machine

Capacity and Motor Power

Choose a machine based on your production needs and space availability. Smaller restaurants may opt for mid-sized machines, while food factories require high-output equipment.Adjustability

Ensure the pasta machine comes with adjustable thickness settings and various molds to cater to different pasta types and production requirements.After-Sales Service and Warranty

Select brands that provide strong after-sales support, including installation assistance, warranties, and technical support, to ensure the machine operates efficiently long-term.

Commercial Dry Pasta Machine

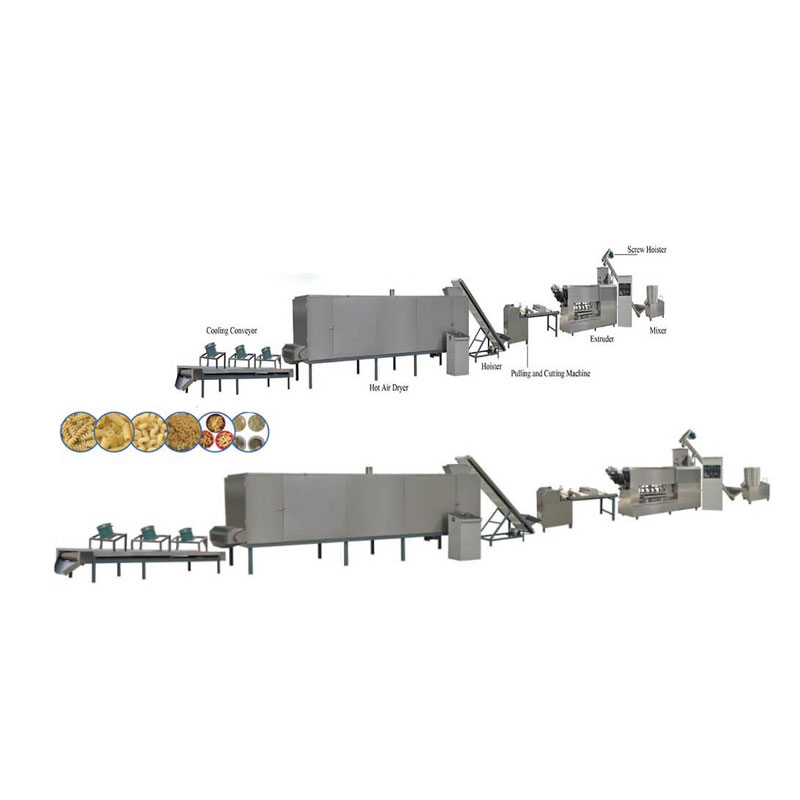

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Production Line

Pasta Production Line Pasta Machine

Pasta Machine Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Multifunction Pasta Machine

Multifunction Pasta Machine Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine Automatic Sausage Linking Machine

Automatic Sausage Linking Machine Semi-automatic Potato Crisps Production Line

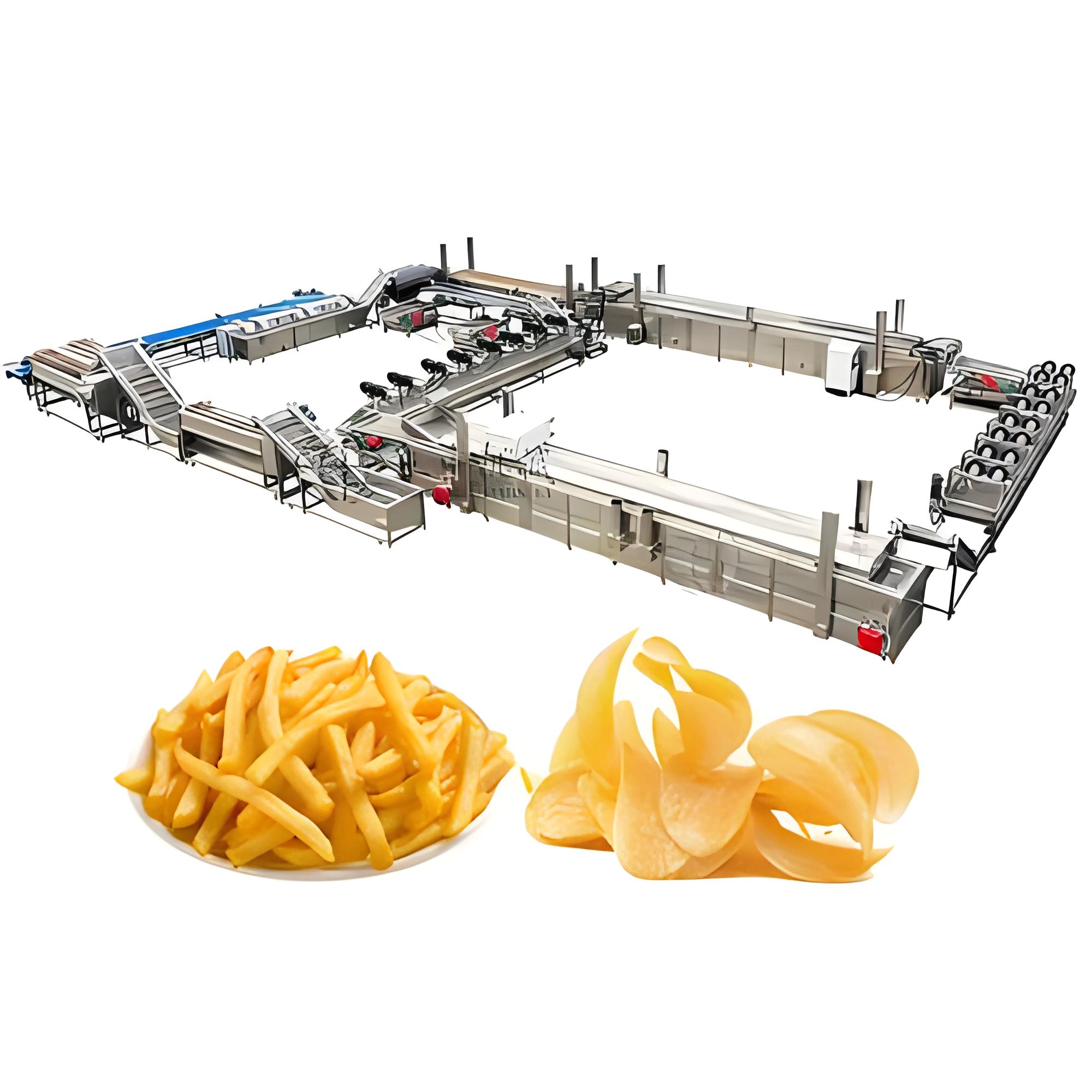

Semi-automatic Potato Crisps Production Line French Fries Production Line

French Fries Production Line Pork Skin Removing Machine

Pork Skin Removing Machine Frozen Meat Slicer

Frozen Meat Slicer Potato Washing&Peeling Machine

Potato Washing&Peeling Machine