1. Product Overview

The Fully Automatic Pasta Production Line is designed for continuous, high-efficiency production of a wide variety of pasta products including spaghetti, penne, macaroni, fusilli, lasagna sheets, and more. Ideal for large-scale pasta manufacturers, frozen food processors, and OEM factories, this line integrates all stages from mixing to drying and packaging.

It ensures stable quality, uniform shapes, food safety, and reduced labor costs through advanced automation and intelligent control systems.

2. Applicable Pasta Types

Short-Cut Pasta: Penne, elbow, fusilli, rigatoni, farfalle, shells

Long-Cut Pasta: Spaghetti, fettuccine, linguine

Sheet Pasta: Lasagna, filled pasta bases

Instant or Pre-cooked Pasta (optional module)

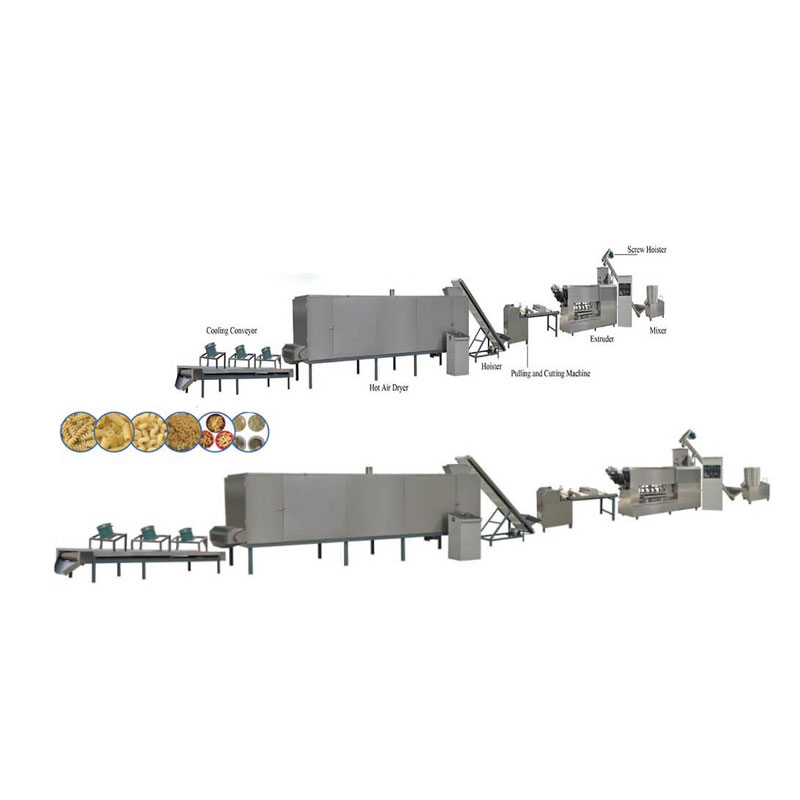

3. Production Process Flow

Raw Material (Flour, Semolina, Additives) → Mixing & Kneading → Extrusion & Shaping → Cutting → Pre-Drying → Drying → Cooling → Packaging

Optional modules: Pasteurization, Flash Freezing, Boiling Line, Vacuum Cooling, Sterile Packaging for ready-to-eat pasta.

4. Standard Production Capacity Options

| Model | Output Capacity | Suitable For |

|---|---|---|

| PPL-200 | 200–300 kg/h | Entry-level industrial use |

| PPL-500 | 500–800 kg/h | Mid-size commercial factories |

| PPL-1000 | 1000–1500 kg/h | High-volume manufacturers |

| PPL-2000+ | 2000+ kg/h | Export & private-label OEMs |

Custom capacity models available on request.

5. Core Equipment Modules

| Equipment | Function |

|---|---|

| High-Speed Flour Mixer | Uniformly mixes flour, water, and additives |

| Pasta Extruder with Die Sets | Shapes pasta using interchangeable molds; cooled by water or air |

| Cutter Unit | Cuts pasta to required length based on recipe and product type |

| Pre-Dryer Tunnel | Stabilizes pasta shape, prevents sticking or collapse |

| Hot-Air Dryer | Multi-stage drying for shelf-stable products |

| Cooling Conveyor or Tunnel | Cools pasta to ambient temperature for safe handling |

| Weighing & Packaging System | Integrated flow-pack, pillow-pack, or tray sealing solutions |

6. Customization Options

| Feature | Customization Options |

|---|---|

| Pasta Shapes | 50+ standard molds or custom die designs |

| Dryer Configurations | Static or continuous belt dryer with precise temp/humidity zones |

| Materials | Food-grade stainless steel (SUS 304 or 316), anti-stick coating |

| Output Packaging | Pillow bag, tray sealing, vacuum, MAP (Modified Atmosphere) |

| Control System | Siemens PLC, multilingual touchscreen, remote diagnostics |

| Add-ons | Cheese injection, pre-boiling tunnel, flash freezer |

7. Suggested Layout (Example: 1000kg/h line)

[Mixing] → [Extrusion] → [Cutting] → [Pre-Drying] → [Main Dryer] → [Cooling] → [Packaging] (Linear or L-shaped layout available based on plant space)

We provide full 3D layout planning and CAD blueprints tailored to your factory’s actual size and configuration.

8. Advantages for B2B Manufacturers

✅ Consistent Quality Control with smart temperature & humidity automation

✅ High Output & Energy Efficiency through advanced heating zones

✅ Labor Cost Reduction via continuous feeding, shaping, and cutting

✅ Low Waste with automatic dough recovery system

✅ Compliance with International Food Safety Standards (HACCP, CE, ISO)

9. Applications

Pasta processing plants (dry or semi-cooked)

Central kitchens for frozen/instant meal kits

Contract manufacturing for retail pasta brands

Export-oriented food production enterprises

10. Optional Deliverables

📄 Technical Data Sheet & Process Flow Diagrams

📐 Custom Plant Layout Design (AutoCAD)

📦 Turnkey Installation & Operator Training

🌍 Export Packaging + Certificate of Origin

🔧 Lifetime Technical Support + Spare Parts Kit

Must-read blogs for bosses