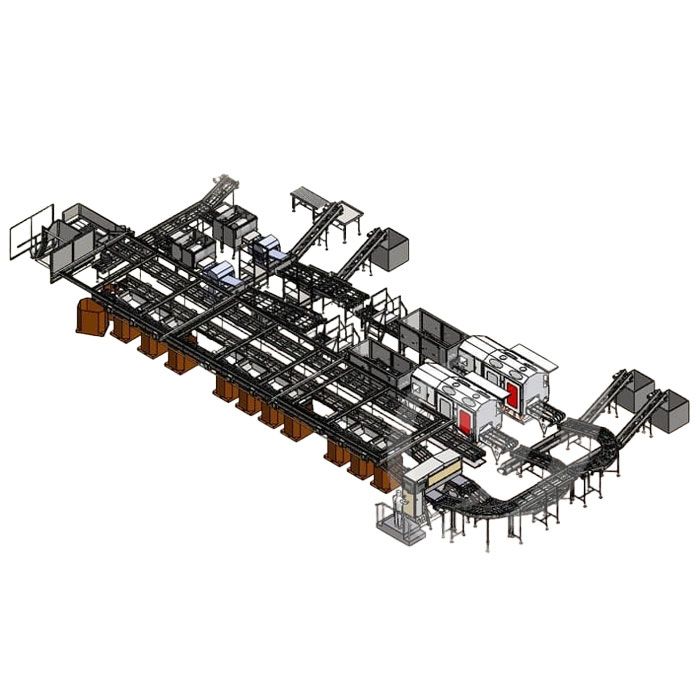

The Aseptic Canning Production Line Equipment is designed for the sterile processing and packaging of liquid and semi-liquid foods such as fruit juice, tomato paste, dairy products, sauces, soups, and purees.

This fully automated line integrates sterilization, aseptic filling, sealing, and packaging processes to ensure long shelf life, product safety, and nutrient preservation — all without the need for chemical preservatives or cold chain logistics.

With advanced sterilization and aseptic technology, this production line is ideal for food and beverage factories, sauce manufacturers, and canning plants looking to improve product quality and achieve international food safety standards such as HACCP, ISO22000, and FDA.

Main Features

⚙️ Complete Aseptic Processing System

Integrates sterilization, aseptic storage, and filling in a fully enclosed environment to prevent microbial contamination.🌡️ High-Temperature Short-Time (HTST) Sterilization

Rapidly sterilizes liquid products at 115–135°C for 10–30 seconds, maintaining nutrients and flavor.🧴 Aseptic Filling and Sealing Unit

Operates in a sterile chamber with HEPA-filtered air, ensuring contamination-free packaging in cans, bottles, or pouches.🧠 PLC + Touch Screen Control System

Intelligent monitoring of temperature, pressure, and flow with real-time data recording and automatic adjustment.🧼 Hygienic Design & Easy Cleaning (CIP/SIP)

Equipped with automatic cleaning and sterilization-in-place systems, reducing downtime and ensuring sanitary operation.

Production Process Flow

Product preparation and mixing

Homogenization and preheating

Ultra-high temperature (UHT) sterilization

Aseptic buffer tank storage

Aseptic can/jar sterilization

Aseptic filling and sealing

Cooling and inspection

Labeling and packaging

Technical Specifications

| Item | Specification |

|---|---|

| Capacity | 1,000 – 15,000 cans/hour |

| Product types | Juice, milk, tomato paste, sauces, soups |

| Sterilization type | UHT / HTST |

| Filling temperature | 25°C – 40°C (adjustable) |

| Control system | PLC + Touch Screen (Siemens / Delta) |

| Material | SUS304 / SUS316 stainless steel |

| Cleaning system | CIP + SIP automatic system |

| Packaging forms | Tin can, glass jar, aluminum can, aseptic bag |

Advantages for Food Producers

✅ Extend Shelf Life Without Preservatives

Aseptic canning keeps products stable for 6–12 months at room temperature.🧾 Maintain Natural Flavor and Nutrition

Short-time sterilization minimizes quality loss compared to conventional retort processing.🧠 Fully Automated Control

Digital system ensures precise temperature and sterilization consistency for each batch.🌍 Meet International Standards

Equipment complies with HACCP, ISO22000, and FDA food safety guidelines for global exports.💰 Reduce Operational Costs

Save on cold storage, logistics, and labor while maintaining high production output.

Applications

Fruit juice and beverage aseptic canning

Tomato paste and sauce canning

Dairy and yogurt-based drinks

Soups, broths, and purees

Baby food and plant-based beverages

About the Manufacturer

As a leading Chinese manufacturer of aseptic and food canning machinery, we provide turnkey production line solutions covering equipment design, layout planning, installation, commissioning, and operator training.

Our aseptic canning systems have been successfully exported to Europe, the Middle East, Southeast Asia, and South America, serving top food brands and OEM factories.

We focus on innovation, automation, and hygiene, helping global processors achieve higher productivity, lower waste, and safer food production.

Must-read blogs for bosses