Tomato Paste Line Factory - Chinese Manufacturer, Factory, Supplier

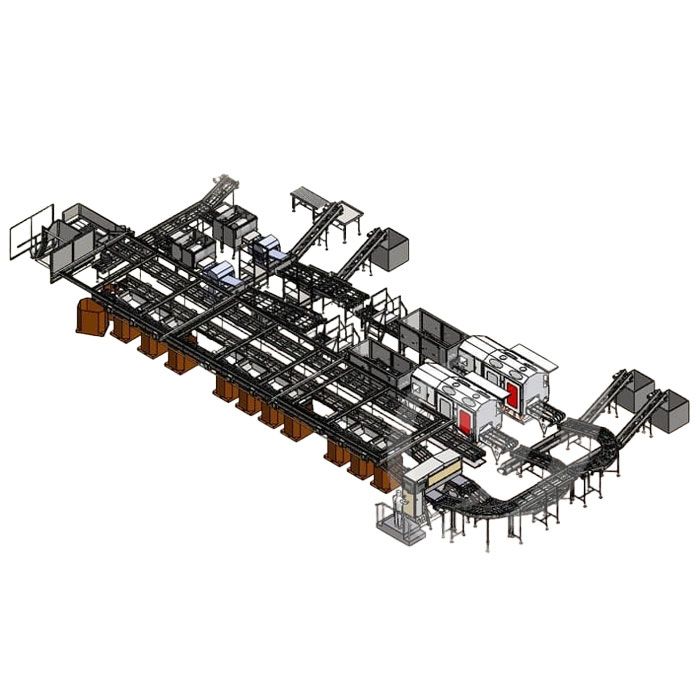

A modern Tomato Paste Line Factory serves as the backbone of large-scale tomato processing, delivering consistency, efficiency, and superior product quality. With global demand for tomato paste and related products steadily increasing, manufacturers require fully integrated facilities designed to handle massive volumes while meeting strict international food safety regulations.

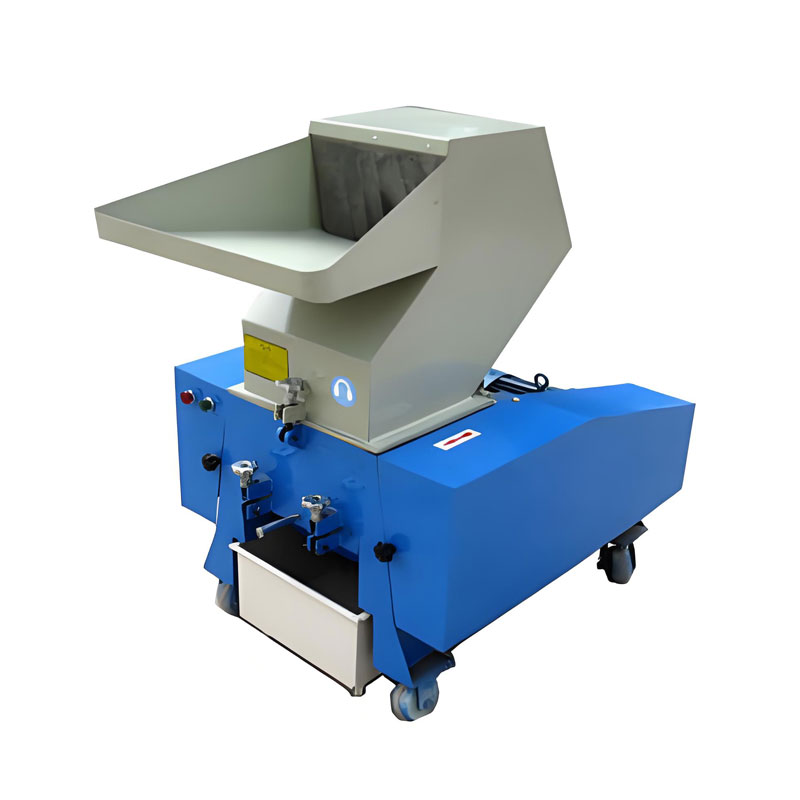

The production journey begins with raw tomato intake and sorting. High-capacity washing and grading systems ensure only premium-quality tomatoes proceed to the next stage. Automated crushers and pulpers then transform raw tomatoes into a uniform slurry, preserving natural color and flavor. In a state-of-the-art Tomato Paste Line Factory, this process is controlled by advanced monitoring systems that maintain precise temperature and consistency.

Concentration is a critical step in tomato paste production. Evaporation units remove excess water, resulting in a rich, dense paste with a standardized Brix level. This ensures the final product meets the specifications required by global food brands and commercial kitchens. Following concentration, pasteurization systems eliminate harmful microorganisms, extending shelf life while retaining natural nutrients.

Durability and hygiene are paramount. Equipment within a Tomato Paste Line Factory is constructed from high-grade stainless steel, ensuring compliance with HACCP, ISO, and FDA standards. Seamless designs make cleaning fast and effective, reducing the risk of cross-contamination. Automation further enhances production by reducing labor requirements and minimizing human error.

An advanced facility is more than just machinery. It includes intelligent packaging solutions, from aseptic filling for bulk storage to retail-ready packaging lines. Real-time data tracking systems provide operational insights, helping manufacturers optimize energy use, reduce waste, and maintain consistent output.

Partnering with an experienced Tomato Paste Line Factory supplier provides additional benefits such as custom production layouts, technical training, and ongoing service support. This holistic approach ensures that every stage of production runs smoothly, from raw material handling to final product distribution.

Investing in a cutting-edge Tomato Paste Line Factory positions food manufacturers for sustainable growth. By leveraging advanced technology and efficient design, businesses can meet rising consumer demand while maintaining profitability and global competitiveness.

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Pasteurized Milk Processing Line

Pasteurized Milk Processing Line Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Paste Grinding Machine

Paste Grinding Machine Tomato Paste Production Line

Tomato Paste Production Line Biscuit Line

Biscuit Line Canned Beans Production Line

Canned Beans Production Line Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Dough Kneader Machine

Dough Kneader Machine Automatic Bone Crushing Machine

Automatic Bone Crushing Machine