Home >

Core Competitive Advantages

Technical Leadership & Customer Value Creation Capabilities

Technology Leadership

· 57 core patents in dynamic cutting algorithms & IoT control

· 8.5% R&D investment ratio with 3-5 new models annually

Agile Supply Chain

· 82% vertical integration of critical components

· 40% inventory turnover improvement via digital systems

Full-Lifecycle Service

· 25% lower TCO for equipment lifecycle

· 24/7 remote diagnostics support

· >95% client retention over 5 years

Green Compliance

· 35% energy consumption reduction

· Certified by CE/FDA/ISO 14064

· ≥92% material recyclability

Project Case

Learn about our efficient and reliable equipment and production line solutions tailored for various food processing industries.

Commercial Kitchen Equipment

Snack Food Processing Equipment

Fruit and Vegetable Processing Equipment

Meat Processing Equipment

Bakery & Cereal Processing Equipment

Seafood Processing Equipment

Dairy Processing Equipment

Seasoning & Sauce Processing Equipment

Cosmetics Processing Equipment

Pet Food Processing Equipment

Ready Meal Processing Equipment

Beer and Beverage Processing Equipment

Relevant News

Stop Rust: Pickled Cucumber Production Line Guide

Why does standard SUS304 fail in pickle factories? Discover the engineering secrets of acid-resistant pickled cucumber production lines and SUS316L material.

Which Large-Scale Canning Production Line Manufacturer Is Better?

1. IntroductionIn recent years, the global food industry has witnessed a significant transformation toward automation and efficiency. As consumers’ demand for s...

How Much Does a Luncheon Meat Canning Production Line Cost?

1. Introduction: Why Luncheon Meat Canning Lines Are in High DemandThe global demand for luncheon meat has been steadily increasing thanks to modern consumers’ ...

How Much Does a Meat Canning Production Line Cost?

1. Introduction: The Growing Market for Canned MeatThe global canned meat industry has been growing rapidly due to rising demand for ready-to-eat protein produc...

How Much Does A Fully Automatic Canning Production Line Cost Per Unit?

Canning production lines are a cornerstone for modern food processing factories, enabling manufacturers to produce shelf-stable products efficiently and consist...

How Much Does A Fruit Canning Production Line Cost?

In today’s fast-changing food industry, fruit canning production lines have become an essential investment for manufacturers looking to preserve seasonal fruits...

Top 8 Brands of Large-Scale Fish Canning Production Lines: 2025 Buyer’s Guide

Discover the BEST 8 brands of large-scale fish canning production lines in 2025! Hermasa, JBT, Qingdao Hongsheng Yuanlin + real factory success stories, pricing...

Fish Canned Production Line Equipment Buying Guide: Expert Tips for 2025 Choices

Discover the ultimate fish canned production line equipment buying guide! From cleaning machines to packaging trends, get pro tips on selecting efficient, safe ...

Which Company Is Better for Canned Food Production Line?

Discover the best canned food production line manufacturers in China. Compare equipment quality, automation level, service, and cost to find the most reliable s...

Cooking Drying Oven

Cooking Drying Oven Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine X-Type Cutting And Stringing Machine

X-Type Cutting And Stringing Machine Remove The Machine

Remove The Machine Smoked Furnace

Smoked Furnace Sausage Automatic Double Wire Binding Machine

Sausage Automatic Double Wire Binding Machine High-Speed Twisting Machine

High-Speed Twisting Machine Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Carrot Processing Line

Carrot Processing Line Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Cooked Meat Shredder Machine

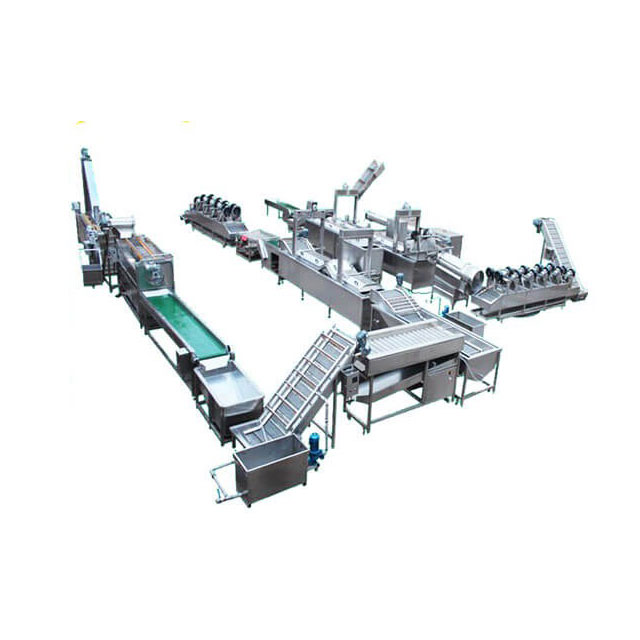

Cooked Meat Shredder Machine Frozen French Fries Production Line

Frozen French Fries Production Line Automatic Noodle Making Machine

Automatic Noodle Making Machine Meat Smoking Machine

Meat Smoking Machine Fish Food Processing Line

Fish Food Processing Line