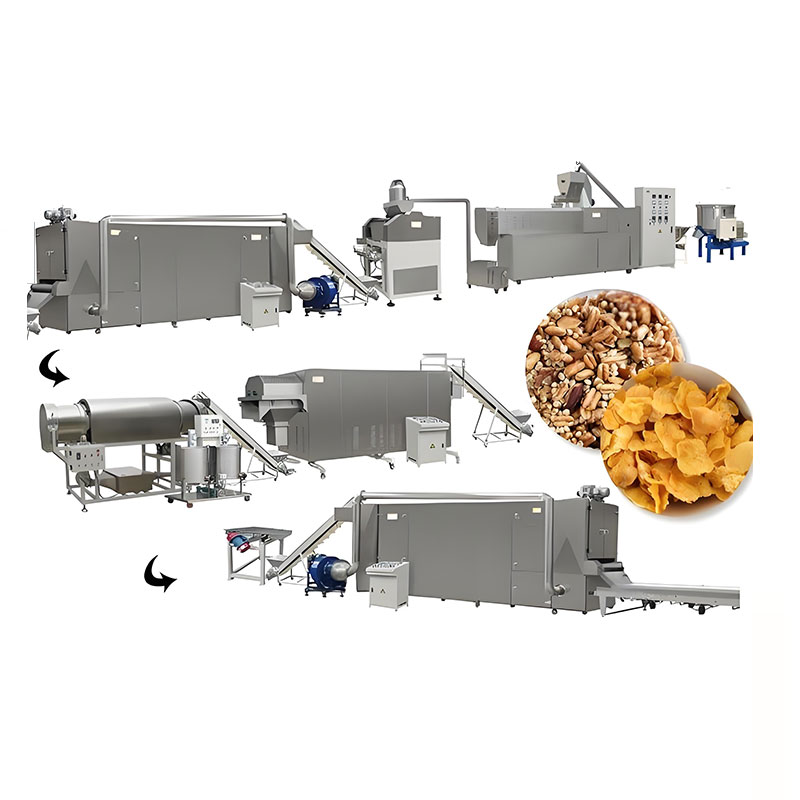

Corn Flakes Machine - Chinese Manufacturer, Factory, Supplier

The corn flakes machine is advanced food processing equipment designed to produce crunchy and golden corn flakes, widely consumed as breakfast cereals and snack products. Built with precision and durability, it integrates extrusion, flaking, drying, and toasting technologies to deliver consistent quality at scale.

Key Features

Efficient Extrusion System: Converts corn flour or maize grits into uniform semi-cooked dough.

Flaking Rollers: Press the dough into thin, smooth flakes with accurate thickness control.

Continuous Drying & Toasting: Ensures crisp texture, appealing color, and long shelf life.

Flavoring & Coating Options: Sugar, honey, chocolate, or savory seasonings can be applied with coating drums.

Hygienic Construction: Stainless steel design for easy cleaning and compliance with food safety standards.

Automation: PLC touch-screen controls with adjustable recipes and low labor requirements.

Applications

Breakfast cereal production for retail packaging.

Snack food industry with customized coatings.

OEM/Private label cereal manufacturing.

Fortified cereal production for the nutrition sector.

Advantages

Capacity options from 100 kg/h pilot units to 1,000+ kg/h industrial lines.

High efficiency and stable output.

Customizable end-products for different markets.

Easy integration with weighing, packing, and sealing machines.

✅ The corn flakes machine provides scalable solutions for startups, mid-size producers, and large cereal factories, enabling consistent product quality and strong ROI.

Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Corn Canning Production Line

Corn Canning Production Line Corn Flakes Food Production Line

Corn Flakes Food Production Line Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Meat Stuffer Machine

Meat Stuffer Machine Shrimp Canning Line Equipment

Shrimp Canning Line Equipment  Frozen Food Production Line

Frozen Food Production Line Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Vegetable Dicing Machine

Vegetable Dicing Machine Cold Chain Rice Production Line

Cold Chain Rice Production Line Paste Grinding Machine

Paste Grinding Machine