🌎 Overview

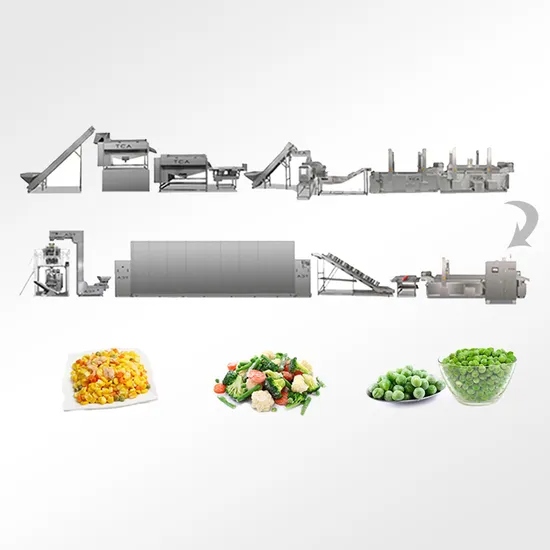

China has emerged as a global powerhouse in manufacturing frozen food processing lines, delivering end-to-end solutions tailored for food factories, central kitchens, and ready-meal producers. These lines are engineered for efficiency, hygiene, and precision, meeting the high standards of global food safety regulations (HACCP, ISO22000, CE, FDA).

Whether you're producing dumplings, vegetables, seafood, meat, or ready meals, Chinese manufacturers offer complete production systems—from preparation to freezing and packaging—with competitive pricing and fast ROI.

🧊 Application Scenarios

Our frozen food processing lines are suitable for:

🥟 Dumplings, Spring Rolls, Wontons

🥩 Frozen Meat Slices, Dice & Blocks (Beef, Pork, Chicken)

🍤 Frozen Seafood (Shrimp, Fish Fillets, Squid Rings)

🥦 IQF Vegetables & Fruits (Green beans, Broccoli, Mango cubes)

🍱 Ready-to-Eat Frozen Meals (Bento, Soups, Stir-fry kits)

🍞 Frozen Bakery Items (Dough balls, Par-baked Bread, Pastries)

🏭 Core Processing Line Components & Capacity Ranges

1. Raw Material Handling & Preprocessing

Functions: Washing, peeling, slicing, dicing, meat deboning, seafood cleaning, vegetable grading

Capacity Range: 500–10,000 kg/h

Features:

Food-grade stainless steel

Sensor-driven auto-sorting

Optional soaking tanks or air bubble washers

2. Blanching / Pre-cooking (Optional)

Functions: Thermal treatment to stabilize color, texture, and flavor (for vegetables, seafood, noodles)

Capacity Range: 300–5,000 kg/h

Equipment Types: Continuous belt blanchers, rotary drum cookers

Temperature Control: 80–100°C, adjustable via PLC

3. Forming / Stuffing / Molding

Functions: Product shaping and filling for items like dumplings, meatballs, patties, fish cakes

Capacity Range:

Dumpling Machine: 6,000–20,000 pcs/h

Patty Former: 1,000–4,000 pcs/h

Meatball Former: 500–3,000 kg/h

Automation: Servo-driven controls, multi-size switching molds

4. Cooking / Frying / Steaming Units

Functions: Cooking or frying for ready-to-eat meals or partially cooked products

Capacity Range: 300–3,000 kg/h

Types:

Continuous Fryer (Oil Temp 160–180°C)

Steam Tunnel for Dim Sum / Buns

Baking & Roasting Ovens

5. Quick Freezing Section (Core System)

Functions: Rapidly reduces food temperature to below -18°C to lock in freshness and texture

Capacity Range: 300–5,000 kg/h

Freezer Types:

IQF (Individual Quick Freezer): For vegetables, berries, seafood

Spiral Freezer: Compact and high capacity for dumplings, ready meals

Tunnel Freezer: For uniform products like patties, nuggets

Freezing Temp: -35°C to -40°C

Freezing Time: 5–25 minutes, adjustable by product

6. Weighing, Sorting & Packaging

Functions: Final sorting, metal detection, weighing, and packaging

Capacity Range: 10–100 packs/min depending on pack size

Options:

Vertical Form Fill Seal (VFFS)

Tray Sealer / Thermoforming

Vacuum Pack / MAP / Nitrogen Flush

Integrated Labeling and Coding Systems

7. Cold Storage & Logistics Automation

Functions: Automatic infeed to cold room or blast freezer, palletizing, and cold-chain dispatch

Features:

Temperature control monitoring

Robotic palletizer or AGV integration

Inventory and batch tracking system (optional)

📊 Technical Highlights

| Feature | Specification |

|---|---|

| Material | SS304 / SS316L for all food-contact parts |

| Automation | Fully automated (PLC+HMI), SCADA optional |

| Cleaning | CIP (Clean-in-Place) integration available |

| Energy Saving | Heat recovery systems in fryers, water circulation in washers |

| Standards | CE, UL, HACCP, ISO22000, FDA-compatible design |

| Modularity | Supports phased expansion & multi-product compatibility |

💼 Why Choose Frozen Food Production Lines from China?

🏭 Comprehensive Manufacturing Ecosystem

Access to all components from steel fabrication to automation locally, reducing costs and delivery time.🌐 Global Project Experience

Exported to 50+ countries with real case studies across Europe, the Middle East, Southeast Asia, Africa, and South America.📦 Turnkey Solutions

From factory layout, equipment manufacturing, FAT testing, to installation, training & after-sales service.💬 Multilingual Support

Engineering documents & PLC interface available in English, Spanish, French, Russian, Arabic, etc.⚙️ Spare Parts Availability

Long-term support with fast global shipping for consumables and key parts.

📈 ROI & Business Impact

| Metric | Benefit |

|---|---|

| Labor Reduction | Save up to 60% on manual labor costs |

| Yield Increase | Reduce material waste by 5–10% |

| Efficiency | Up to 24/7 operation with minimal downtime |

| ROI Payback | 12–20 months typical for mid- to large-scale projects |

| Compliance | Smoother access to international markets |

📍 Case Study: 5,000 kg/day Frozen Vegetable Line – Southeast Asia

Products: Broccoli, green beans, carrots

Line Configuration: Washing → Blanching → IQF → Sorting → Packing

Outcome:

Reduced energy cost by 22% using Chinese energy-efficient IQF freezer

Gained new retail customers after passing EU food audits

ROI achieved in 14 months

📦 Delivery Includes

Detailed factory layout & P&ID

Main equipment with PLC controls

FAT (Factory Acceptance Test) report and video

Operation & maintenance manuals

On-site engineer installation & training (optional)

Spare parts kit (12 months recommended)

Compliance certificates (CE, ISO, material traceability)

🤝 Start Building Your Frozen Food Factory Today

We help food processors grow with automated, scalable, and hygienic frozen food solutions. Contact our team to get:

📐 Customized Layout Drawing

💰 Cost Estimate & ROI Analysis

🔍 Free Consultation with Engineers

📄 Project Proposal for Approval/Loan Applications

👉 Get in touch today and accelerate your frozen food business with Made-in-China technology.

Must-read blogs for bosses