Fully Automatic Pasta Making Machine - Chinese Manufacturer, Factory, Supplier

A fully automatic pasta making machine is an advanced piece of equipment designed to streamline the process of pasta production. These machines are engineered to automate various stages of pasta making, from mixing and kneading the dough to extruding and cutting the pasta into desired shapes and sizes. By integrating multiple functions into a single system, these machines offer a high level of efficiency, consistency, and quality control, making them ideal for both small-scale producers and large pasta manufacturers.

The pasta production process begins with the preparation of the dough. The fully automatic machine incorporates flour mixers, water dispensers, and kneading systems that ensure the dough is perfectly mixed and ready for extrusion. Using advanced technology, these machines are capable of adjusting parameters like dough hydration and mixing time, ensuring the right texture and elasticity for different pasta types, such as spaghetti, penne, fusilli, and ravioli.

Once the dough is prepared, the next step involves extrusion, where the dough is forced through specialized molds to create pasta shapes. The extruder mechanism is equipped with customizable dies, allowing manufacturers to produce a wide range of pasta shapes with precision. Some models also feature cutting blades that can be adjusted for various lengths and thicknesses, ensuring uniformity across the batch.

One of the key benefits of a fully automatic pasta making machine is its automation capabilities, which minimize human intervention. This leads to cost savings in labor, reduced production time, and consistent product quality. Moreover, these machines are designed for easy maintenance, with features like self-cleaning systems that simplify cleanup between batches.

For businesses aiming to meet growing demand, these machines provide significant scalability. They can handle high volumes of production while maintaining a high level of precision, making them suitable for both artisanal and industrial pasta production. Furthermore, many modern automatic pasta machines are equipped with digital controls and smart sensors, offering enhanced monitoring of production parameters and enabling real-time adjustments for optimal performance.

In conclusion, the fully automatic pasta making machine is an invaluable asset for pasta manufacturers looking to improve production efficiency, maintain high standards of quality, and keep pace with market demands. With a range of advanced features and flexibility, these machines are revolutionizing the pasta-making industry, ensuring businesses can deliver fresh, high-quality pasta consistently.

Pasta Machine

Pasta Machine Meat Bun Machine

Meat Bun Machine Automatic Noodle Making Machine

Automatic Noodle Making Machine Multifunctional Noodle Making Machine

Multifunctional Noodle Making Machine Dough Divider Rounder

Dough Divider Rounder Flour Mixing Machine

Flour Mixing Machine Dough Kneader Machine

Dough Kneader Machine Dough Roller Machine

Dough Roller Machine Pizza Cone Equipment

Pizza Cone Equipment Donut Making Machine

Donut Making Machine Portable Flake Ice Machine

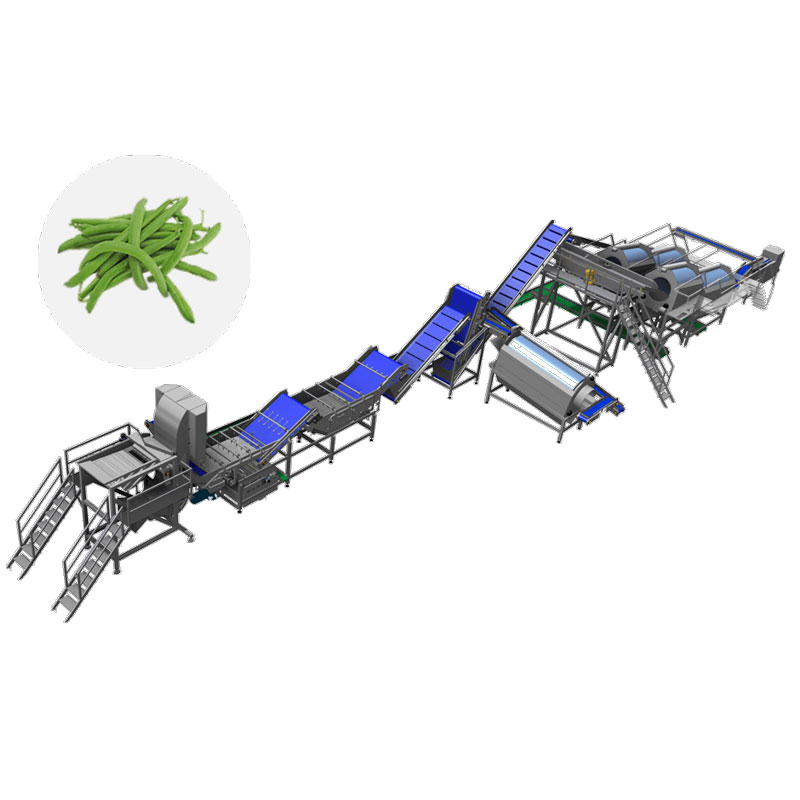

Portable Flake Ice Machine Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Spinach Canned Canned Food Canning Production Line

Spinach Canned Canned Food Canning Production Line Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Bowl Cutter

Bowl Cutter Meat Canned Food Production Line

Meat Canned Food Production Line Mayonnaise Production Line

Mayonnaise Production Line