How Industrial Dicing Machines Transform Your Processing Workflow

The Efficiency Dilemma in the Food Processing Industry

In recent years, the global food processing industry has been undergoing a profound transformation. Consumers are demanding higher standards of product quality, consistency, and safety. Meanwhile, supply chains are evolving rapidly, pushing manufacturers to achieve both speed and standardization across operations.

However, most food processing enterprises are facing common challenges:

✅ Labor Shortages & Rising Costs

Food production has long relied on manual labor for repetitive processes like sorting and cutting. With labor shortages becoming more acute and wages rising, manufacturers face increasing difficulties in recruitment and retention.

✅ Shorter Lead Times & Higher Quality Expectations

B2B clients such as restaurant chains, supermarkets, and fresh food brands now demand faster delivery and more consistent, standardized products. Manual or semi-automated production lines often struggle to keep pace.

✅ Stricter Food Safety Regulations

Global regulations require reduced human intervention and more controlled processes to prevent contamination, pushing enterprises toward automation and standardized workflows.

Conclusion: Improving production efficiency, reducing labor dependency, and enhancing consistency are now strategic imperatives for food manufacturers.

Industrial Dicing Machines: The Double Engine of Precision and Efficiency

Industrial dicing machines play a crucial role in the pre-processing stage of food production, offering far more than just cutting functionality. These machines deliver:

Higher efficiency

Lower operating costs

Greater stability

Enhanced standardization

Core Functional Advantages

| Function | Value for Efficiency |

|---|---|

| Automatic feeding/discharge | Reduces labor, ensures continuous workflow |

| Multi-size precision dicing | Supports diverse product needs, minimizes downtime |

| High-speed batch processing | Daily output up to 5-20 tons, far beyond manual capabilities |

| Stainless steel design, easy to clean | Ensures compliance with hygiene and food safety standards |

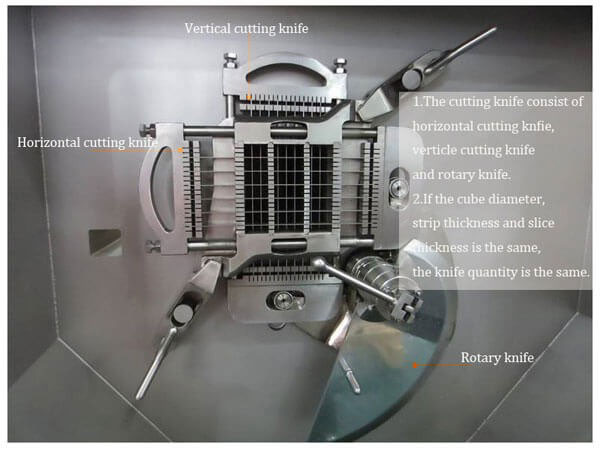

Modern industrial dicing machines integrate slicing, strip cutting, and dicing functions into a modular, flexible solution adaptable to meat, fruit, vegetables, dairy, and snack products.

How Dicing Machines Drive Significant Efficiency Gains

1️⃣ Shorter Processing Time, Higher Output Capacity

Manual operations face inherent limits:

Cutting speed depends entirely on labor capacity

Fatigue reduces efficiency over time

Variability between shifts leads to inconsistent output

With dicing machines, daily processing capacity increases 3-6x, transforming labor-intensive multi-shift production into streamlined, automated workflows.

▶ Case Data:

Processing output comparison for a ready meal company:

| Method | Labor Required | Daily Output | Unit Production Cost |

|---|---|---|---|

| Manual Cutting | 20 people | 1 ton | High |

| Semi-Automatic | 10 people | 2 tons | Medium |

| Dicing Machine | 2 people | 6 tons | Low |

Production capacity increased by 300-500%, labor costs reduced by over 80%, and unit costs decreased by more than 40%.

2️⃣ Lower Labor Costs, Solving Recruitment Challenges

In today's labor market, expanding manpower is increasingly impractical. Industrial dicing machines provide a reliable solution for cost reduction and efficiency improvement:

One machine requires only 1-2 operators

No skilled labor required, reducing training costs

Stable output mitigates risks from staff turnover, leave, or absenteeism

ROI Analysis:

Average annual labor cost per operator: $10,000

Reducing 20 workers saves $200,000 annually

Annual machine depreciation & maintenance: $30,000

Full return on investment achievable within the first year

Dicing machines shift factories from “people finding work” to “work finding people” — do more with less.

3️⃣ Standardized Output Optimizes Downstream Processes

Dicing machines enhance not only their own efficiency but also drive improvements across the entire processing chain through precise, consistent cutting results:

| Process Stage | Manual Cutting Impact | Dicing Machine Benefits |

|---|---|---|

| Marination | Uneven sizes, inconsistent flavor absorption | Uniform size, consistent marination |

| Packaging | Irregular shapes slow packing, inconsistent weights | Uniform dices, faster automated packaging |

| Freezing | Varied sizes disrupt freezing cycles, storage inefficiencies | Standardized pieces, optimal freezing, storage efficiency |

| Product Display | Poor appearance affects retail appeal | Consistent appearance enhances shelf impact |

Outcome: From raw material to final product, processes become smoother, quality more uniform, efficiency higher, waste minimized.

Key Technological Advantages of Modern Dicing Machines

✅ Precision Cutting, Adjustable Specifications

Adjustable dice sizes from 5mm to 30mm via precision knife group settings — quickly switch to meet diverse market needs.

✅ Smart Control Systems

PLC with touch-screen operation, variable frequency drives for speed and pressure adjustments, ensuring consistent quality across materials.

✅ Automatic Protection & Stability

Anti-jam technology with auto-stop protection, enabling continuous, reliable operations and reducing downtime.

✅ Food-Grade Hygiene Compliance

All-stainless-steel construction, rounded corners, quick-disassemble design for thorough cleaning, compliant with HACCP, CE standards.

Practical Applications & Industry Performance

1️⃣ Frozen Food Factories

▶ Products: diced fruits, vegetables, meats for freezing

✅ Boost output by 300%

✅ Uniform freezing, reduced logistics costs

✅ Seamless integration with IQF lines for efficient flow

2️⃣ Central Kitchens & Ready Meal Facilities

▶ Products: diced meat, potatoes, carrots for ready meals

✅ Faster processing, shorter delivery cycles

✅ Uniform dice for even marination, consistent quality

✅ Reduced manual handling, lower contamination risk

3️⃣ Snack & Convenience Foods

▶ Products: diced jerky, meat snacks, flavor cubes

✅ Consistent shapes enhance consumer appeal

✅ Lower defect rates, reduced waste

Real-World Case Study: A Fruit & Vegetable Processor Doubles Efficiency

Background

Previously relied on manual + semi-automatic methods

Production capacity limited growth potential

High defect rates, inconsistent quality

Transformation

Invested in 6 high-speed industrial dicing machines, restructured workflows and logistics.

Results Comparison

| Metric | Before | After | Efficiency Gains |

|---|---|---|---|

| Labor Input | 40 workers | 6 workers | ↓85% |

| Daily Output | 5 tons | 20 tons | ↑400% |

| Defect Rate | 8%-10% | <2% | ↓ Significant |

| Lead Time | 10 days | 3-5 days | ↓ 50% |

| Customer Satisfaction | Complaints common | Dramatic improvement | Increased long-term contracts |

Result: Stabilized delivery schedules, acquired new clients, increased market share by over 20%, annual revenue growth in the millions.

Future Outlook: Automation Will Be the Industry Standard

✅ The Direction is Clear

The future of food processing will center on:

➡ Standardized production

➡ Fully automated lines

➡ Data-driven management

Industrial dicing machines are already the essential foundation for efficiency in large-scale factories, central kitchens, and supply chains.

✅ Beyond Efficiency: Building Competitive Advantage

✅ Faster fulfillment

✅ Cost advantage

✅ Consistent product quality

✅ Enhanced brand professionalism

Automation investments today will shape the scalability and profitability of tomorrow’s market leaders.

Conclusion: Is It Time to Upgrade Your Processing Speed?

If your factory struggles with:

❗ Labor shortages

❗ Insufficient capacity

❗ High defect rates

❗ Uncontrolled costs

❗ Delayed deliveries

Consider this: an industrial dicing machine isn’t just another piece of equipment. It’s a gateway to a more efficient, stable, and sustainable production model.

In the next phase of industry competition, those who embrace automation earlier will capture market opportunities faster.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?