Automated Sandwich Production Lines: Solve Bottlenecks, Reduce Labor Costs, and Scale with Consistency

📈 Growing Demand, Limited Output — What's Holding You Back?

The global demand for pre-packaged sandwiches is growing rapidly—driven by busy consumers, convenience store chains, online grocery platforms, and airline catering. Yet, many food producers are still relying on manual labor to prepare, assemble, and package sandwiches.

This outdated approach is becoming a serious bottleneck for business growth.

⚠️ 5 Common Pain Points of Manual Sandwich Production

1. Low Throughput, Missed Orders

Manual labor can only produce a few hundred sandwiches per hour.

High-volume orders during holidays or promotions lead to delays and lost revenue.

2. Rising Labor Costs and High Turnover

You need large teams to handle repetitive prep and assembly work.

Hiring, training, and retention are increasingly difficult and costly.

3. Inconsistent Product Quality

Hand-placed ingredients lead to uneven portion sizes, crooked layers, and packaging issues.

Inconsistencies damage your brand reputation with wholesale or retail buyers.

4. Food Safety Risks

Too many touchpoints increase the risk of cross-contamination.

Manual cleaning is time-consuming and prone to errors, affecting audit readiness.

5. No Scalability

Expanding your production capacity means hiring more workers and renting more space—not efficient or sustainable.

🧠 Fact: Businesses that fail to automate will struggle to meet hygiene standards, customer expectations, and supply chain scalability in the next 3–5 years.

✅ How an Automated Sandwich Production Line Solves These Problems

Investing in a smart, modular automated sandwich assembly line is the most effective way to overcome current bottlenecks and prepare for future growth.

Key Benefits :

| Business Challenge | Automated Solution |

|---|---|

| Low production output | Up to 5,000 sandwiches/hour with full automation |

| High labor cost | Reduce staff by 60–80%, with only 2–3 operators needed |

| Product inconsistency | Precision ingredient placement and consistent packaging |

| Food safety concerns | Stainless steel, wash-down design meets HACCP, FDA, CE |

| Limited scalability | Modular design supports new SKUs and future capacity growth |

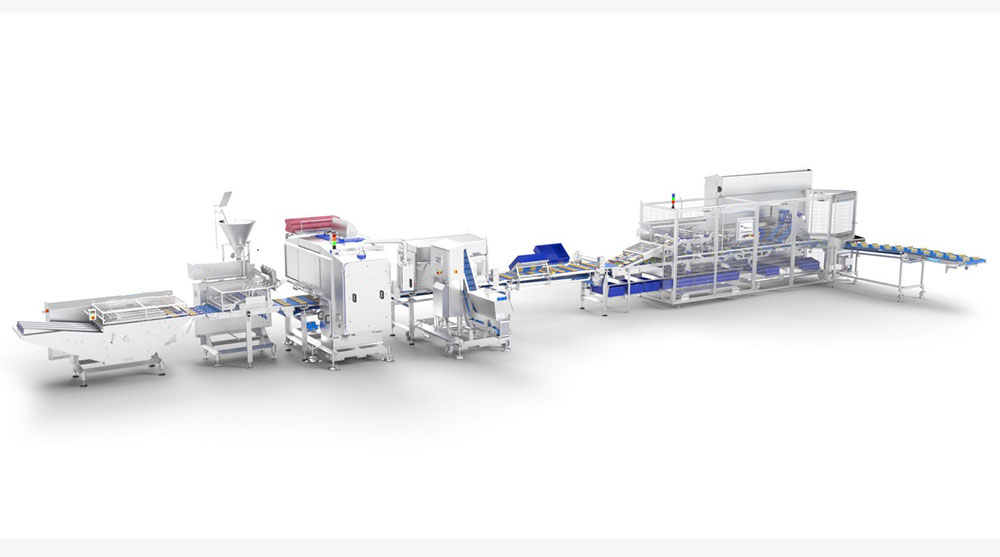

⚙️ What Does a Sandwich Automation Line Include?

SEO-rich feature breakdown:

Bread Slicer: Precise cutting of loaves, rolls, or sub buns

Sauce Spreader: Uniform application of mayonnaise, butter, mustard, etc.

Ingredient Dispenser: Controlled placement of lettuce, cheese, meats, eggs

Assembly Station: High-speed layer alignment and sandwich compression

Packaging Machine: Wrapping, sealing, labeling, and date coding

Metal Detector / Weight Checker: Ensures product safety and accuracy

⚙️ Optional modules for tray sealing, MAP packaging, or salad-sandwich combo packs are also available.

📊 ROI Analysis: Is It Worth the Investment?

Absolutely. The return on investment for sandwich automation equipment is often achieved in 12 to 18 months, with long-term gains in efficiency, compliance, and growth.

Example: Mid-sized Sandwich Factory (10,000 units/day)

| Metric | Manual Production | Automated Production |

|---|---|---|

| Labor Required | 20 workers | 4 operators |

| Monthly Labor Cost | $60,000 | $12,000 |

| Productivity | 500 units/hour/person | 4,000–5,000 units/hour (entire line) |

| Payback Period | — | 12–14 months |

| Equipment Lifespan | — | 8–10 years |

💡 You’re not just buying a machine. You’re freeing your business from labor dependency and unlocking long-term profitability.

🏭 Who Should Invest in Automated Sandwich Production?

Who needs sandwich machines | sandwich production target customers

Centralized kitchens and food factories

Airline catering suppliers

Convenience store food suppliers

Cloud kitchen & meal-prep brands

Exporters of ready-to-eat meal boxes

Institutional or school meal contractors

If you're producing 3,000–30,000 sandwiches/day, automation will bring immediate efficiency.

📌 What to Consider When Choosing a Sandwich Automation System

Before making a decision, use this checklist to evaluate your supplier:

✅ Is the equipment customizable for your SKUs (triangle, sub, club sandwiches)?

✅ Can the machine handle high-moisture and delicate fillings?

✅ Is the hygiene standard compliant with your country’s regulations?

✅ Are spare parts and service support readily available?

✅ Can you scale the system later with add-on modules?

📥 Tip: Download our free "Sandwich Line Buyer’s Checklist" to assess all factors.

📣 Ready to Escape Production Limits?

You’ve already built the demand. Now it's time to scale your operation.

An automated sandwich production line gives you the tools to:

✅ Boost output

✅ Lower costs

✅ Protect quality

✅ Improve hygiene

✅ Grow your brand

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?