Smart Leap from Fresh to Final: How Fruit Processing Lines Revolutionize Modern Production

In today’s fast-paced food manufacturing world, Fruit Processing Lines have become indispensable tools for companies aiming to transform fresh fruits into high-quality, shelf-stable, and value-added products like juices, purées, concentrates, canned fruit, jams, and ready-to-eat fresh cuts.

Whether you're a startup entering the fruit processing industry or an established manufacturer seeking to scale, this guide will walk you through the benefits, structure, and key decision points of investing in a modern, automated fruit processing line.

🍊 Why Invest in an Automated Fruit Processing Line?

✅ 1. Boost Efficiency & Output

Automated lines handle large volumes of fruit with speed, precision, and consistency. Compared to manual operations, automation enables higher throughput, allowing you to meet growing market demand and expand your business footprint without scaling labor.

✅ 2. Ensure Consistent Product Quality

Automation minimizes human error, ensuring that every batch of juice, puree, or fruit snack meets consistent standards in flavor, texture, appearance, and safety. For brand-driven companies, product consistency is a must.

✅ 3. Reduce Labor Costs

While the upfront investment is significant, the reduction in repetitive, labor-intensive tasks leads to major savings in wages, onboarding, supervision, and HR overhead in the long run.

✅ 4. Enhance Food Safety & Hygiene

Modern processing lines are made of food-grade stainless steel and engineered to reduce human contact with raw materials. Most include CIP (Clean-in-Place) systems for automated sanitation and comply with global food safety standards like HACCP, FDA, and CE.

✅ 5. Minimize Waste & Optimize Resources

From precision cutting and peeling to controlled juice extraction, these systems maximize usable yield. Some even feature by-product utilization modules—turning peels into animal feed or essential oil extracts.

✅ 6. Extend Shelf Life

Techniques like pasteurization, sterilization, freezing, and drying significantly extend the shelf life of fruit products, opening access to new markets while reducing spoilage losses.

✅ 7. Offer Flexibility & Scalability

Many lines are designed for multi-fruit and multi-product adaptability—ideal for responding to shifting consumer preferences and seasonal availability.

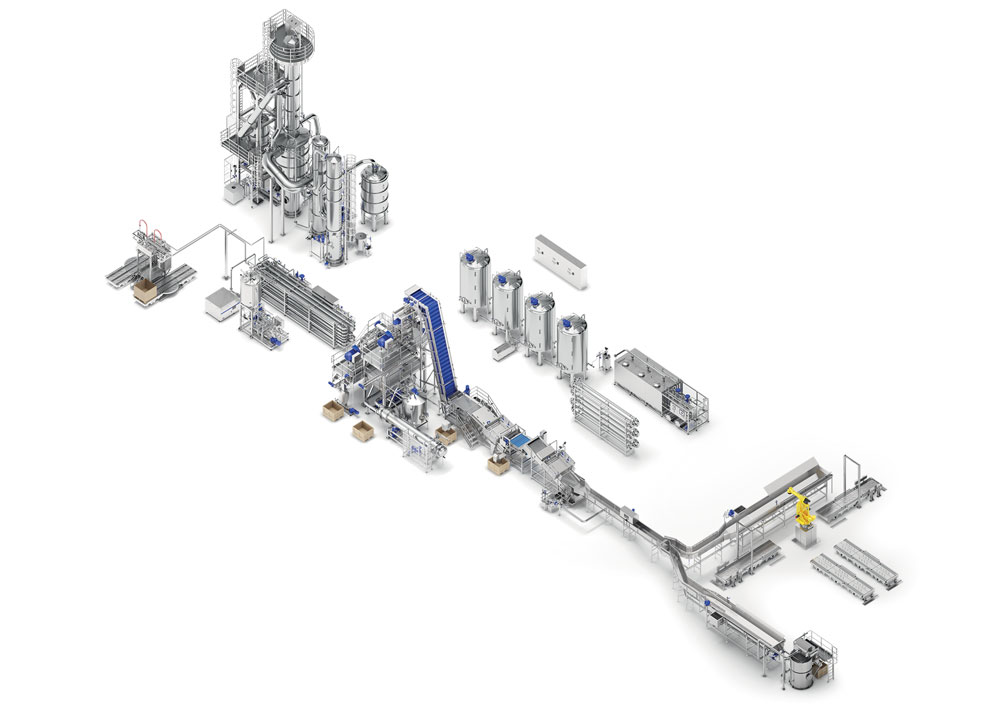

🏗️ Core Stages in a Typical Fruit Processing Line

While configurations vary depending on fruit type and final product, most industrial fruit processing lines follow these key stages:

1. Receiving & Washing

Receiving hopper or tank – accepts fresh fruit in bulk

Washing machine – removes dirt, residues, and pesticides

(bubble washers, spray washers, or brush washers depending on the fruit)

2. Sorting & Grading

Sorting conveyor or optical sorter – removes spoiled or unripe fruit

Grading system – classifies by size, ripeness, or color

3. Preparation / Pre-treatment

Peeling/De-coring/De-stoning machines – specific to fruit type

(e.g. mango de-pitters, apple peelers, pineapple corers)Slicing/Dicing/Crushing – shapes fruit or prepares it for juice extraction

4. Processing & Extraction

Pulpers & Refiners – separate pulp from skin/seeds

Juice extractors – belt presses, screw presses, or centrifuges

Blanchers – soften fruit, deactivate enzymes, improve texture

Evaporators – concentrate juices/purées for storage or transport

5. Thermal Processing / Preservation

Pasteurization systems (HTST/UHT) – kill pathogens, preserve flavor

Sterilizers – ensure aseptic packaging readiness

6. Filling & Packaging

Filling machines – volumetric, gravity, or piston fillers

Sealing & capping – vacuum sealers, capper units

Labelers & coders – add traceability and branding

Cartoning & palletizing systems – ready for logistics

7. Auxiliary Equipment

Conveyors – transport between stages

CIP systems – automated, closed-loop cleaning

Pumps & tanks – handle liquids and pulps

PLC + SCADA controls – real-time monitoring and automation

🔍 Types of Fruit Processing Lines

Choosing the right configuration depends on your product goals, target market, and operational scale.

| Product Type | Processing Focus | Key Technologies |

|---|---|---|

| Fruit Juice (NFC/Concentrate) | Extraction, pasteurization, filling | Belt press, evaporators, HTST/UHT |

| Purée & Pulp | Refining and aseptic filling | Pulpers, sterilizers, bag-in-box fillers |

| Canned Fruit | Cutting, blanching, sugar syrup dosing, canning | Can fillers, retort sterilizers |

| Dried Fruit | Cutting, sulfuring (optional), drying | Hot air, vacuum, or freeze dryers |

| IQF Frozen Fruit | Washing, cutting, fast freezing | Tunnel freezer, vibratory freezer |

📈 Key Buying Considerations

Before selecting a fruit processing solution, consider the following:

Fruit Type & Condition – Tropical fruits require different handling than temperate ones

Target Product Formats – Liquid (juice) vs. semi-solid (purée) vs. solid (canned)

Daily Production Volume – Batch or continuous processing?

Shelf Life Goals – Fresh, refrigerated, frozen, or ambient storage?

Compliance Requirements – Which food safety certifications are necessary?

Budget vs ROI – Factor in automation’s long-term labor and yield savings

Scalability – Can the line be upgraded as your market grows?

💡 Final Thought: From Orchard to Market—Smarter, Safer, Faster

Investing in a modern fruit processing line is about more than machinery—it’s about future-proofing your business in a competitive, quality-sensitive market.

Whether you produce juice, purée, dried fruits, or canned fruit, an automated solution can unlock:

✅ Lower unit costs

✅ Improved quality control

✅ Extended shelf life

✅ Streamlined compliance

✅ Sustainable use of resources

📩 Looking to configure your ideal fruit processing line?

Contact us for a free consultation, evaluate your needs systematically.

Let automation transform your fruit—from fresh to final—smarter than ever.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?