Automatic Ice Maker Factory In China - Chinese Manufacturer, Factory, Supplier

China has emerged as a global powerhouse in the manufacturing of refrigeration equipment, and the Automatic Ice Maker Factory In China stands as a prime example of this industrial excellence. Leveraging advanced engineering, robust supply chains, and precise manufacturing processes, these factories are redefining the standards of automated ice production worldwide.

An Automatic Ice Maker Factory In China is not merely a production site; it is a sophisticated ecosystem where innovation meets functionality. These factories specialize in crafting a wide array of ice-making machines, ranging from compact commercial units to large-scale industrial ice systems. Precision-engineered components, coupled with state-of-the-art automation, ensure that every machine delivers consistent performance with minimal human intervention.

The demand for reliable ice makers spans across multiple sectors — food processing, hospitality, fisheries, healthcare, and logistics. Chinese manufacturers have meticulously tailored their designs to meet these varying requirements. A leading Automatic Ice Maker Factory In China typically integrates intelligent control systems, energy-efficient refrigeration technology, and corrosion-resistant materials to ensure longevity and operational stability.

In a fiercely competitive global market, cost efficiency remains a key differentiator. Chinese factories excel not only in technological innovation but also in supply chain optimization, allowing them to offer competitive pricing without compromising quality. This balance has earned the Automatic Ice Maker Factory In China a solid reputation among distributors, importers, and end-users across Europe, North America, Southeast Asia, and beyond.

Furthermore, these factories emphasize rigorous quality control at every stage of production. From raw material inspection to final product testing, stringent protocols guarantee that each ice maker performs to exacting standards. Many facilities also hold internationally recognized certifications, underscoring their commitment to excellence and compliance with global safety and environmental benchmarks.

Partnering with an Automatic Ice Maker Factory In China offers more than just access to reliable equipment. It opens the door to comprehensive OEM and ODM services, tailored solutions, and responsive after-sales support. These advantages make Chinese ice maker manufacturers a preferred choice for businesses seeking dependable partnerships and long-term value.

AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine SC Series Bullet Ice Maker

SC Series Bullet Ice Maker SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine AP Series Flake Ice Machine

AP Series Flake Ice Machine SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine AM Series Crescent Ice Maker

AM Series Crescent Ice Maker SD Square Ice Series Upright Ice Makers

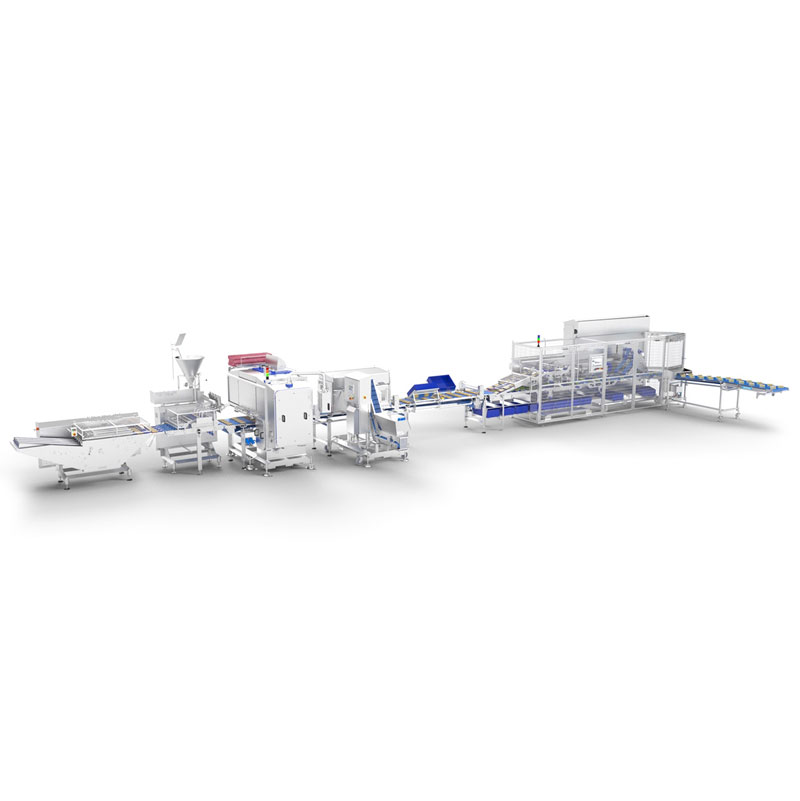

SD Square Ice Series Upright Ice Makers Sausage Processing Line

Sausage Processing Line Meat Processing Line Equipment

Meat Processing Line Equipment Sardine Canned Food Production Line

Sardine Canned Food Production Line Sandwich Production Line

Sandwich Production Line Egg Canning Production Line

Egg Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine