Home >

Related Products

Core Competitive Advantages

Technical Leadership & Customer Value Creation Capabilities

Technology Leadership

· 57 core patents in dynamic cutting algorithms & IoT control

· 8.5% R&D investment ratio with 3-5 new models annually

Agile Supply Chain

· 82% vertical integration of critical components

· 40% inventory turnover improvement via digital systems

Full-Lifecycle Service

· 25% lower TCO for equipment lifecycle

· 24/7 remote diagnostics support

· >95% client retention over 5 years

Green Compliance

· 35% energy consumption reduction

· Certified by CE/FDA/ISO 14064

· ≥92% material recyclability

Project Case

Learn about our efficient and reliable equipment and production line solutions tailored for various food processing industries.

Commercial Kitchen Equipment

Snack Food Processing Equipment

Fruit and Vegetable Processing Equipment

Meat Processing Equipment

Bakery & Cereal Processing Equipment

Seafood Processing Equipment

Dairy Processing Equipment

Seasoning & Sauce Processing Equipment

Cosmetics Processing Equipment

Pet Food Processing Equipment

Ready Meal Processing Equipment

Beer and Beverage Processing Equipment

Relevant News

The Blueprint of Excellence: Inside a Water Purification Equipment Factory

Why Water Purification Factories Matter in a Thirsty WorldThe Global Water Crisis: A Call to ActionThe planet’s freshwater reserves are collapsing under the wei...

Comparing Water Purification Equipment Suppliers: What to Look For in a B2B Partner

Why Supplier Selection Matters in Water Purification OutcomesChoosing a water treatment supplier isn’t a procurement task—it’s a strategic operational decision....

Choosing Water Purification Equipment Based on Specific Contaminant Removal Needs

The Critical Link Between Contaminant Profiles and Purification SuccessGeneric water systems crumble under the weight of complex contaminant matrices. A system ...

Maintenance Tips to Maximize the Lifespan of Your Commercial Water Purification Equipment

The Critical Role of Maintenance in Commercial Water PurificationNeglecting maintenance transforms water purification systems from assets into liabilities. Part...

Selecting the Right Water Purification System for Pharmaceutical Manufacturing Compliance

Understanding the Importance of Water Purity in Pharmaceutical ManufacturingWater is the unsung hero of pharmaceutical production, serving as a solvent, ingredi...

Procurement Guide for High-Flow Water Purification Equipment for Factories

Step 1: Clearly Define Your NeedsComprehensive Analysis and Evaluation of Water SourcesDetailed Classification of Water Source TypesIs your factory's water ...

RO Reverse Osmosis vs. Ultrafiltration Membrane Commercial Water Purification Equipment: Advantages

1. Reverse Osmosis (RO) Membrane Commercial Water Purification EquipmentPrinciple of OperationReverse osmosis is a pressure-driven membrane separation process. ...

How to Solve Loud Noise Issues in Commercial Water Purification Equipment

1. Pump Noise - A Deep Dive into Causes and SolutionsCavitation - Detailed Explanation and Prevention StrategiesCavitation occurs when the pressure within the p...

Commercial Water Purification Equipment for High Hardness Water

For businesses grappling with the challenges posed by high water hardness, implementing the right water purification equipment is not merely a matter of conveni...

How to Choose the Right Commercial Water Purification System

Choosing the right commercial water purification system is a crucial decision that will impact your business operations, product quality, and the health of your...

Centrifugal Dewatering Machine

Centrifugal Dewatering Machine YL-W-06 Commercial Water Purification Equipment

YL-W-06 Commercial Water Purification Equipment YL-W-05 Commercial Water Purification Equipment

YL-W-05 Commercial Water Purification Equipment YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment YL-W-03 Commercial Water Purification Equipment

YL-W-03 Commercial Water Purification Equipment YL-W-02 Commercial Water Purification Equipment

YL-W-02 Commercial Water Purification Equipment YL-W-01 Commercial Water Purification Equipment

YL-W-01 Commercial Water Purification Equipment Brush Potato Washing Peeling Machine

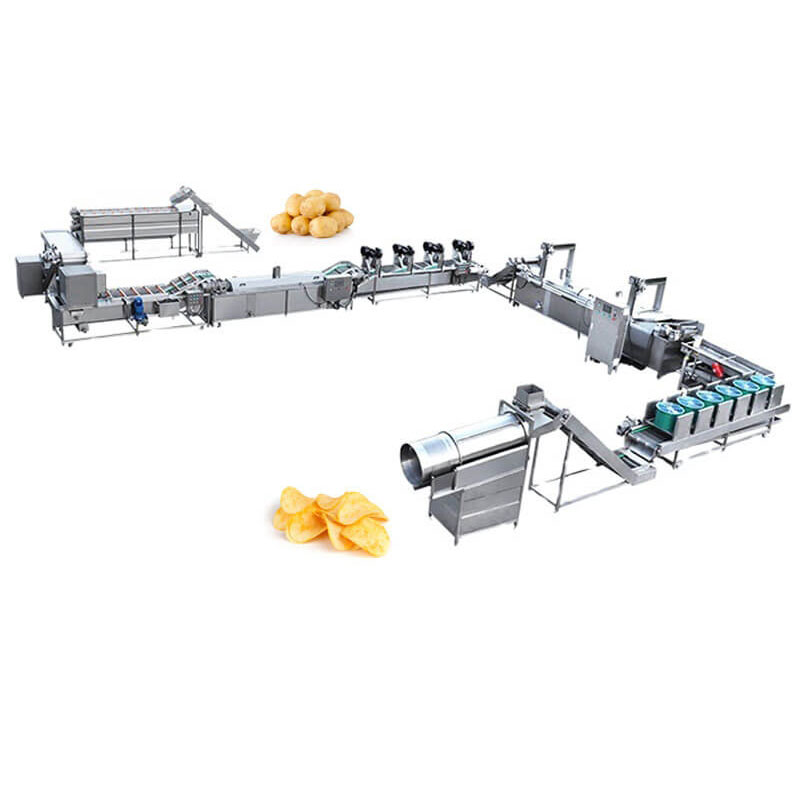

Brush Potato Washing Peeling Machine Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Canned Fish Production Line

Canned Fish Production Line YL-980 Digital Metal Detector

YL-980 Digital Metal Detector Double-Tank Vegetable Washing Machine

Double-Tank Vegetable Washing Machine Gizzard Peeling Machine

Gizzard Peeling Machine Mayonnaise Production Line

Mayonnaise Production Line The Double-Door Steaming Cabinet With A Viewing Window

The Double-Door Steaming Cabinet With A Viewing Window