Venison Processing Equipment - Chinese Manufacturer, Factory, Supplier

The meticulous processing of harvested cervine meat, commonly known as venison, is paramount to ensuring both culinary excellence and the mitigation of spoilage. The selection of appropriate Venison Processing Equipment is therefore not merely a logistical consideration, but a foundational element in the journey from field to table.

Initial stages of transformation necessitate robust implements capable of efficiently handling the carcass. Gambrels, typically constructed from high-tensile steel, serve as crucial suspension devices, facilitating both skinning and evisceration. Flaying knives, characterized by their ergonomic design and razor-sharp, often curved blades, are indispensable for the expeditious removal of the hide. For larger operations, automated dehiding machinery can significantly enhance throughput, albeit at a higher capital outlay.

Subsequent to the initial breakdown, the carcass undergoes a process of butchering and portioning. Here, band saws, with their reciprocating blades and precise cutting action, are the workhorses of the operation, enabling the creation of primal cuts and smaller portions with minimal wastage. For the production of ground venison, heavy-duty meat grinders, often equipped with various sized grinding plates, are essential. Furthermore, for those engaged in the fabrication of charcuterie, sausage stuffers and meat mixers become indispensable adjuncts to the processing arsenal.

The final stages of venison processing revolve around preservation and packaging. Vacuum sealers, employing the principle of atmospheric evacuation, extend the shelf life of the processed meat by inhibiting oxidative degradation and microbial proliferation. Industrial-grade freezers, capable of rapidly reducing the temperature of the venison to sub-zero levels, further contribute to long-term preservation. The utilization of appropriate packaging materials, such as food-grade polyethylene films, is also critical in maintaining the integrity of the final product.

In the contemporary landscape of venison processing, numerous manufacturers offer a comprehensive suite of equipment tailored to varying scales of operation. Among these, entities such as the china yuanlin factory have emerged as significant players in the provision of diverse processing solutions. The judicious selection of Venison Processing Equipment from reputable sources is a critical determinant in achieving optimal yield, ensuring food safety, and ultimately, maximizing the inherent value of this esteemed wild game.

Fresh Meat Slicing Portioning Machine

Fresh Meat Slicing Portioning Machine Automatic Cooked Meat Slicing Machine

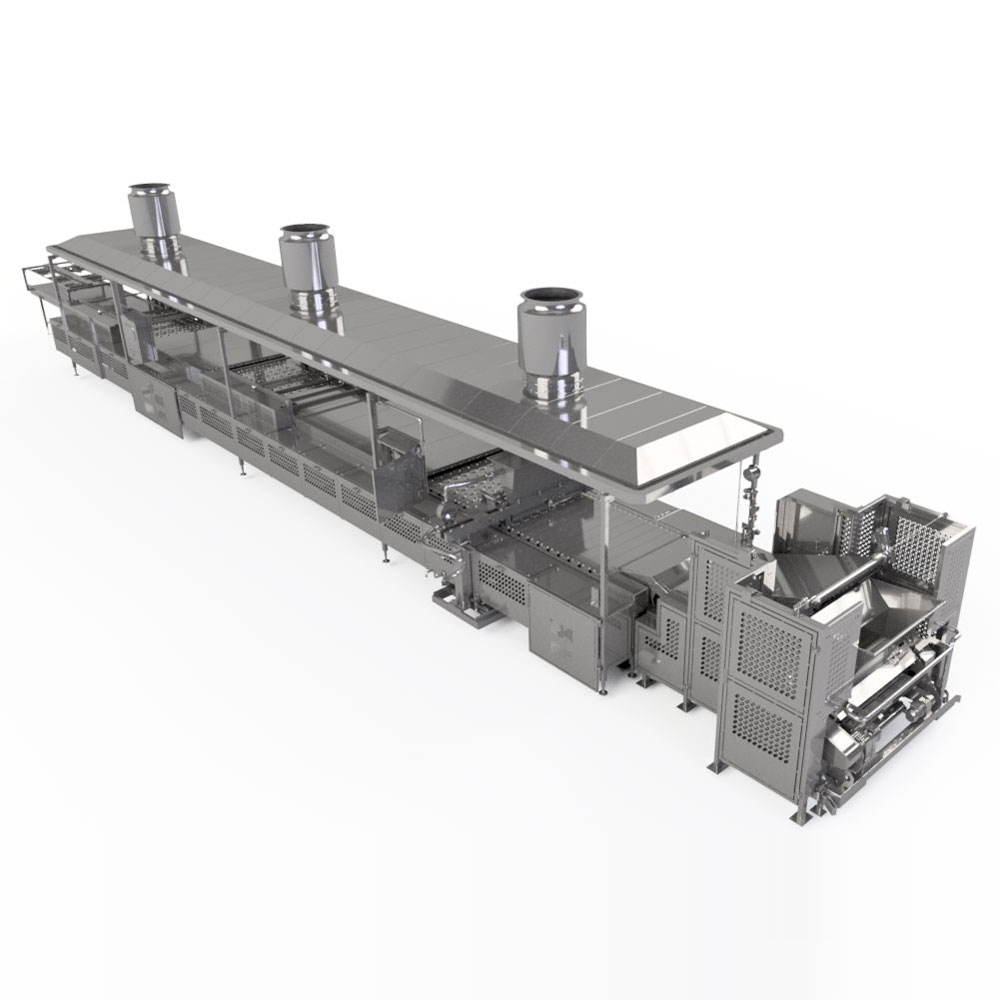

Automatic Cooked Meat Slicing Machine Cooking Drying Oven

Cooking Drying Oven Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine X-Type Cutting And Stringing Machine

X-Type Cutting And Stringing Machine Remove The Machine

Remove The Machine Smoked Furnace

Smoked Furnace Sausage Automatic Double Wire Binding Machine

Sausage Automatic Double Wire Binding Machine High-Speed Twisting Machine

High-Speed Twisting Machine Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Model 200 Frequency Conversion High Speed Chopper

Model 200 Frequency Conversion High Speed Chopper Frozen Meat Grinder

Frozen Meat Grinder Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Automatic Meatball Production Line

Automatic Meatball Production Line YL-W-03 Commercial Water Purification Equipment

YL-W-03 Commercial Water Purification Equipment Pancake Production Line

Pancake Production Line Automatic Twisting Quantitative Sausage Stuffer Machine

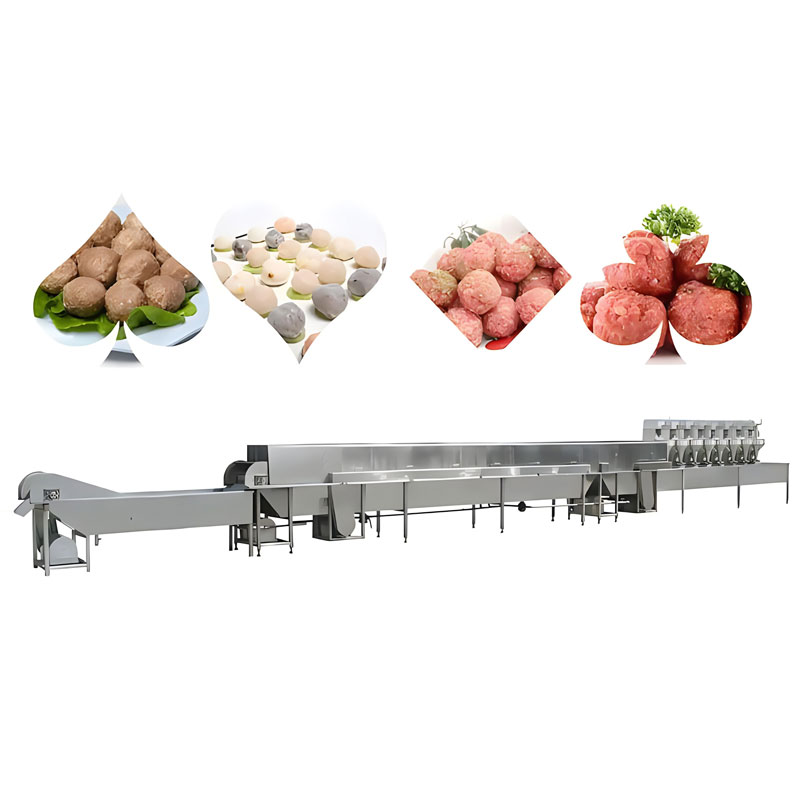

Automatic Twisting Quantitative Sausage Stuffer Machine Meatball Production Line

Meatball Production Line Dutch Canned Fish Production Line

Dutch Canned Fish Production Line