Multifunctional pasta production line has always featured high technology, reliability, and flexibility in order to ensure not only the production of traditional shapes but also special shapes by means of cutting devices and additional machines. The automatic macaroni line capacity is featuring output from 80 up to 120 Kg per hour are available, by “batch” or continuous extruders equipped with vacuum extrusion device and static or continuous dryers, depending on the customers' specific requirements. We can also customize solutions of other capacities.

Raw materials: adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

Capacity: 80-120kg/h, we can also customize other capacities according to your needs.

The macaroni processing workshop should be (minimum): width: 5m length: 23m height: 3.0 m

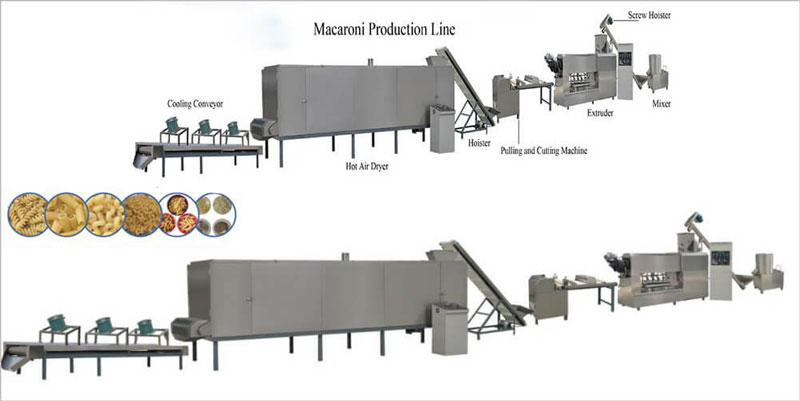

Flowchart:Mixing system---Extrusion system----Cutting system---Drying system---Frying system---Flavoring System --Packing system

Voltage: all the voltage frequency of the machines can be made to fit your work environment.

Machines materials: All the machines are made of stainless steel to prolong the service life of the equipment.

Final Products Show

I. Rice Powder Mixer

Mixer makes the raw material adding to water and liquid chemical additive fully mixed.

Mixing Machine Features

1. This part that contacts mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design, good seal and avoids leaking the material.

Rice Powder Mixer Specification

Type | BJ |

| Dimensions | 700×800×1100mm |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 3kw |

II. Screw Hoister

Used for conveying the raw material to the feeder of the pasta extruder from the material mixer.

Screw Hoister Specification

Type | BJ |

| Dimensions | 2000*800*2300mm |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 1.1kw |

III. Single-screw Macaroni Extruder DL-3000

Use the advanced frequency control skill, stable working process, and less power consumption;

The screw is made by alloy steel, having a longer life-span;

Auto heat-control system, easy work, and the more accurate parameter;

Macaroni Extruder DL-3000 Specification

Type | DL-300 |

| Dimensions | 3200*1100*2000mm |

| Input Voltage | 380V/50Hz |

| Main motor power | 60kw |

| Total power | 79kw |

IV. Pulling and Cutter Machine

Pulling cutter is used to cutter long square pipe, circle pipe.

Cutter is made of one part with stainless steel net and cut part.

It is very easy to operate, adopting frequency controlling.

Pulling and Cutter machine Specifications

Type | BJ |

| Dimensions | 2000*800*1500mm |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 2kw |

V. Hoister conveyor

Hoister can be classified into big and small according to the hoister height and the level distance.

The conveyor can be classified into rubber tape and stainless steel.

Hoister conveyor Specifications

Type | BJ |

| Dimensions | 1300*800*2400mm |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 1.5kw |

VI. Drying Oven

It is 5-layer oven, used to bake and dry the food. The oven can bake all kinds of the inflating food, pet food, TVP/TSP food, peanut, nut, chew nut and so on.

Drying Oven Features

The oven has a compact structure, little space occupying, large drying area, slight radiating heat and high thermal efficiency.

The belt and the heat preservation use the stainless steel; it is suitable for the food industry.

The running speed of the belt net can be controlled (frequency).

The temperature can be controlled willfully and designed according to the need.

Adjustable transit speed of net belt with accurate temperature control device.

Double-roller chain and chain drive make stable and smooth running.

Sliding board bottom of the dryer for easy cleaning.

Suitable to dry non-fried extrusion snacks, nutritional powder, breadcrumb, pet food, soybean protein, etc.

Drying Oven Technical data

Used to carry expanded food to the next device

Air Cooling Conveyor Technical data

Type | BJ |

| Dimensions | 8000*800mm |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 1.1kw |

Relevant Service for Pasta Making Line

1. Output: 80-120Kg/h

2. Square for the workshop: 100 ㎡and height 3.0 m

3. Real Power Consumption: 60 kW

4. Voltage / Frequency: 380V / 50Hz (can be changed to your country voltage)

5. Dimension (m): 20.0 x 5.0 x 2.4 m

6. Warranty: At least 1 year from the date of completion of the commissioning.

7. Installation/Operation/ Service/ Maintenance Manual: Provided In English.

Must-read blogs for bosses