Meat Processing Tables - Chinese Manufacturer, Factory, Supplier

Meat Processing Tables are indispensable fixtures in modern meat processing facilities, designed to optimize hygiene, workflow efficiency, and operator safety. These specialized tables serve as the primary workspace where butchering, cutting, trimming, and portioning of meat products take place. Crafted with precision and durability, Meat Processing Tables are engineered to withstand rigorous daily use, while facilitating compliance with stringent food safety regulations.

Typically constructed from high-grade stainless steel, these tables offer exceptional resistance to corrosion, stains, and bacterial contamination. The non-porous surface ensures that cross-contamination risks are minimized, making sanitation processes seamless and effective. Additionally, many Meat Processing Tables incorporate ergonomic design elements such as adjustable heights and sloped surfaces, which enhance operator comfort and reduce fatigue during extended periods of work.

Beyond their robust construction, Meat Processing Tables often feature integrated drainage systems that allow liquids to swiftly drain away, maintaining a dry and safe working environment. Some models come equipped with antimicrobial coatings and seamless welds, further elevating hygiene standards critical in meat handling operations.

Incorporating modular components, these tables can be customized with attachments such as cutting boards, hooks, and storage shelves, tailored to specific operational requirements. This adaptability makes Meat Processing Tables not merely static workstations but dynamic tools that streamline processing workflows and increase throughput.

Investing in high-quality Meat Processing Tables transcends mere functionality; it signals a commitment to product quality and worker safety. In an industry where contamination or inefficiency can result in costly setbacks, the choice of processing equipment plays a pivotal role. Superior tables contribute to consistent meat preparation standards, reducing waste and enhancing the overall quality of the final product.

Furthermore, their durability ensures longevity, decreasing the frequency of replacements and lowering long-term operational costs. For meat processing businesses aiming to balance productivity with regulatory compliance and workplace safety, selecting the right Meat Processing Tables is a fundamental step towards achieving excellence.

Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Chicken Nugget Processing Line

Chicken Nugget Processing Line Dough Kneader Machine

Dough Kneader Machine AP Series Flake Ice Machine

AP Series Flake Ice Machine Cooking Drying Oven

Cooking Drying Oven Robotic Rice Production Line

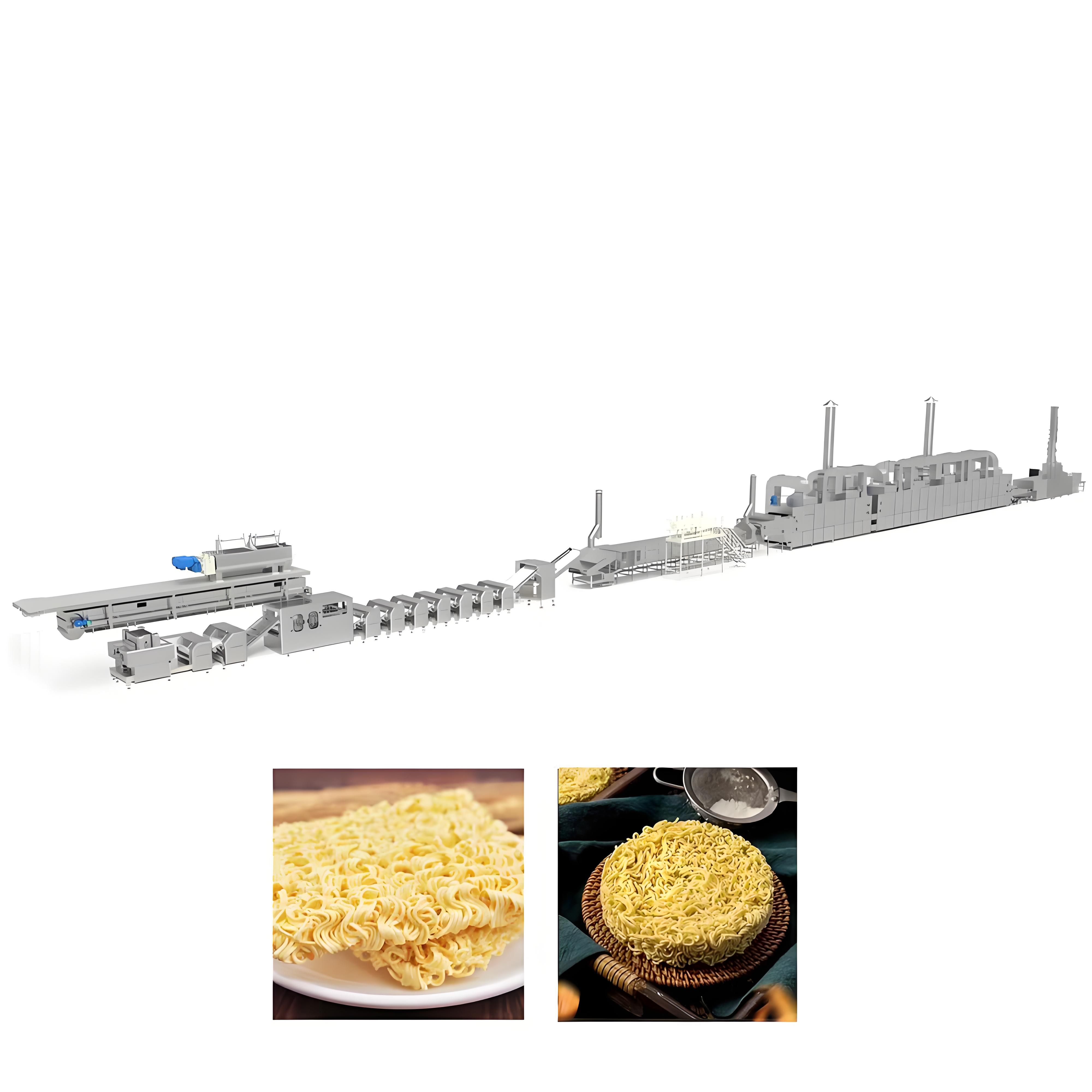

Robotic Rice Production Line Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line Fully Automatic Canned Tuna Processing Production Line

Fully Automatic Canned Tuna Processing Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine