Commercial Pasta Equipment Factory - Chinese Manufacturer, Factory, Supplier

A Commercial Pasta Equipment Factory serves as the backbone of large-scale pasta production, supplying industrial-grade machinery designed for efficiency, consistency, and long-term performance. These factories are more than manufacturing hubs; they are innovation centers where advanced engineering meets the culinary art of pasta making.

Within a Commercial Pasta Equipment Factory, every machine is crafted with precision. From heavy-duty dough mixers and high-capacity extruders to automated shaping and cutting systems, each component is designed to withstand continuous operation while maintaining strict quality control. Food-grade stainless steel construction ensures durability and compliance with global hygiene standards such as HACCP and ISO 22000.

The technology developed by a reputable Commercial Pasta Equipment Factory allows producers to handle a wide variety of pasta types and shapes with minimal changeover time. Intelligent control panels enable operators to adjust hydration, extrusion pressure, and cutting speed with exacting accuracy, ensuring uniform texture and appearance in every batch.

Efficiency is paramount. Machines from a Commercial Pasta Equipment Factory are often integrated into fully automated production lines, seamlessly connecting mixing, extrusion, drying, and packaging processes. This streamlined approach reduces labor costs, minimizes waste, and enhances overall productivity.

Customization is another defining feature. A trusted Commercial Pasta Equipment Factory tailors its equipment to match the client’s recipes, production capacity, and facility layout. Whether the requirement is for traditional long pasta, short-cut varieties, or innovative artisanal designs, the factory delivers equipment optimized for both output and product uniqueness.

Beyond machinery, a dependable Commercial Pasta Equipment Factory offers comprehensive services—installation, operator training, scheduled maintenance, and rapid spare parts supply—to ensure that production lines operate at peak efficiency over the long term.

For pasta producers seeking to elevate their operations, aligning with a leading Commercial Pasta Equipment Factory means more than purchasing equipment; it means investing in a partnership that blends technological excellence with industry expertise. The result is a production environment capable of meeting rising consumer demand while consistently delivering pasta of exceptional quality.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Machine

Pasta Machine Multifunction Pasta Machine

Multifunction Pasta Machine Automatic Meatball Making Machine

Automatic Meatball Making Machine Biscuit Making Machine

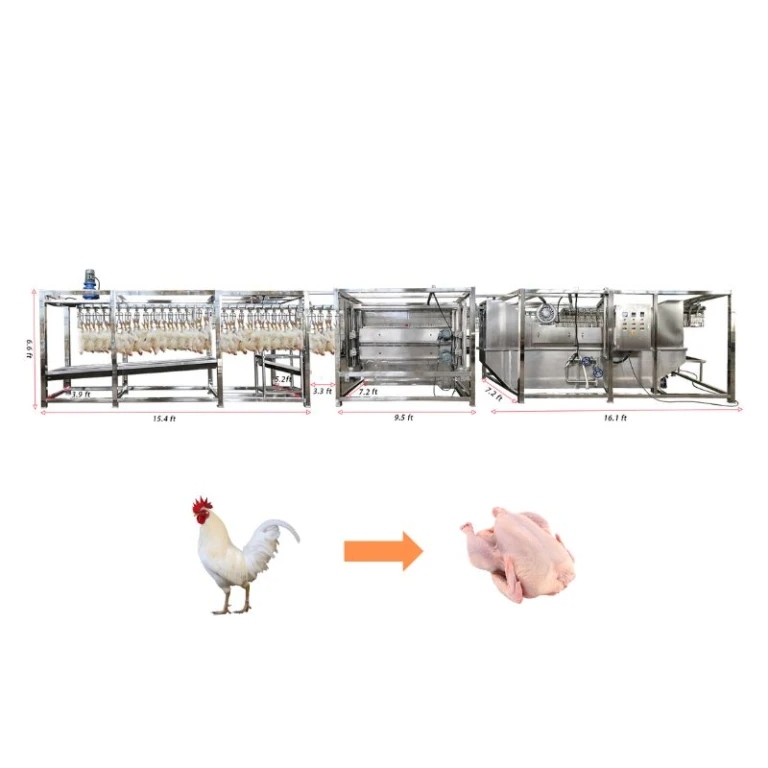

Biscuit Making Machine Chicken Production Line

Chicken Production Line Potato Chip Line

Potato Chip Line Canned Food Filling And Sealing Line

Canned Food Filling And Sealing Line Blackfish Canning Production Line

Blackfish Canning Production Line Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Membrane Skinner

Membrane Skinner