Pasta, a beloved staple in cuisines worldwide, owes its versatility and deliciousness to the intricate art of pasta making. However, behind every perfectly cooked spaghetti or ravioli lies a world of sophisticated machinery designed to streamline and perfect the pasta production process. Whether you're a commercial pasta manufacturer or a home chef looking to elevate your pasta game, understanding pasta processing equipment is essential. This comprehensive guide explores the various types of pasta processing equipment, their functions, and how they contribute to producing high-quality pasta.

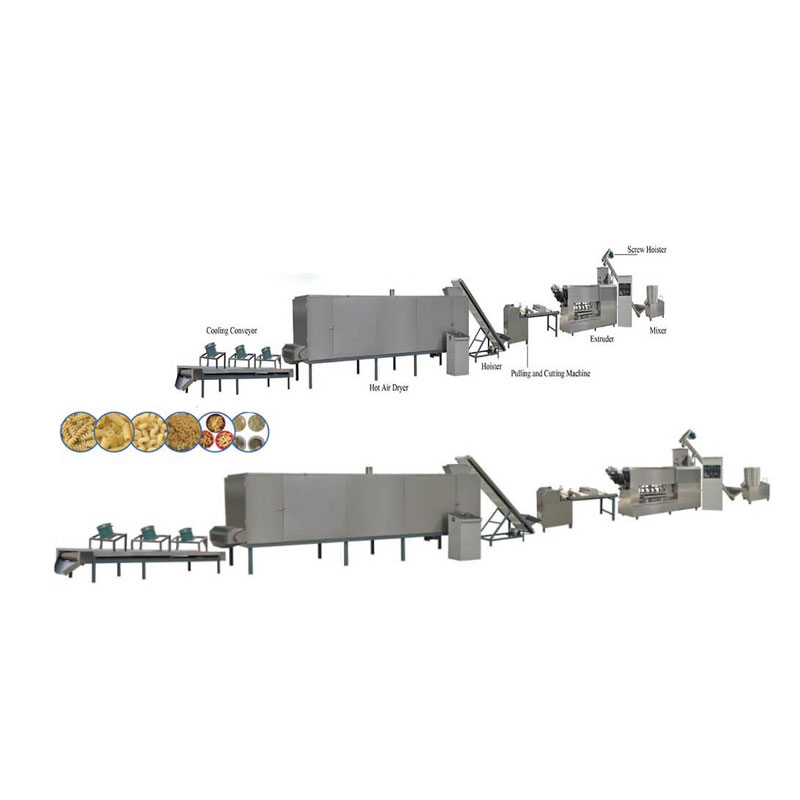

Pasta processing equipment plays a crucial role in ensuring the consistency, quality, and efficiency of pasta production. These machines are designed to handle different stages of pasta making, from mixing and kneading the dough to shaping, extruding, and drying the final product. By automating these processes, pasta processing equipment not only saves time and labor but also enhances the precision and uniformity of the pasta produced.

Dough mixers and kneaders are the backbone of any pasta production line. These machines mix the ingredients (typically flour and water) into a homogeneous dough, ensuring the right consistency and texture.

- Fork Kneaders: Ideal for small-scale production, fork kneaders mimic the traditional hand-kneading process, resulting in dough with excellent elasticity.

- Spiral Kneaders: These are more suitable for larger batches, offering high-speed kneading that ensures a uniform dough texture. Spiral kneaders come in various capacities, from 12 kg to 25 kg of dough per cycle.

Dough sheeters roll the dough into thin, even sheets, which can then be cut or shaped into various pasta forms. This equipment is vital for producing lasagna sheets, ravioli, and other flat pasta types.

- Manual Sheeters: Perfect for artisanal pasta makers, manual sheeters allow for precise control over the dough thickness.

- Automatic Sheeters: These are designed for high-volume production, capable of continuously rolling out dough sheets with consistent thickness.

Pasta extruders are used to create shaped pasta such as penne, rigatoni, and fusilli. The dough is pushed through dies of various shapes, producing uniform pasta pieces.

- Single-Screw Extruders: Suitable for small to medium-scale production, single-screw extruders are versatile and easy to operate.

- Twin-Screw Extruders: These are designed for large-scale production, offering higher output and the ability to handle a wider range of ingredients and pasta shapes.

Drying is a critical step in pasta production, as it affects the shelf life and cooking properties of the final product. Pasta dryers remove moisture from the pasta, ensuring it is dried evenly and thoroughly.

- Long-Goods Pasta Dryers: Specifically designed for drying long pasta such as spaghetti and fettuccine, these dryers ensure even drying while minimizing energy consumption.

- Short-Goods Pasta Dryers: Used for drying short pasta shapes like macaroni and penne, these dryers offer consistent and high-quality results.

For pasta varieties such as gnocchi, ravioli, and cappelletti, specialized machines are available to streamline production.

- Gnocchi Machines: These machines shape and cut gnocchi dough into uniform pieces, ensuring consistent size and texture.

- Ravioli Machines: Ravioli machines fill and seal pasta sheets to create perfectly shaped ravioli, with options for different sizes and fillings.

When selecting pasta processing equipment, it's essential to consider several factors to ensure you choose the right machinery for your needs.

The capacity of the equipment should match your production needs. For commercial manufacturers, high-capacity machines that can handle large batches are crucial, while smaller, more flexible machines may be suitable for artisanal or home use.

High-quality materials, such as stainless steel, ensure durability and hygiene. Look for machines that are easy to clean and maintain, as this will save time and effort in the long run.

Automated machines offer greater efficiency and consistency, reducing the need for manual intervention. Features such as programmable settings and digital controls can enhance precision and ease of use.

Versatile machines that can handle multiple pasta shapes and sizes provide greater flexibility and allow you to expand your product range without investing in additional equipment.

Investing in high-quality pasta processing equipment offers several benefits, including:

- Consistency: Automated machines ensure uniformity in pasta shape, size, and texture, enhancing the overall quality of the product.

- Efficiency: By streamlining the production process, these machines save time and labor, allowing for higher output and faster turnaround times.

- Cost Savings: Although the initial investment may be significant, high-quality equipment reduces waste and operational costs in the long term.

- Scalability: As your production needs grow, scalable equipment allows you to increase capacity without compromising on quality.

Several brands are renowned for their high-quality pasta processing equipment, offering a range of machines to suit different production needs.

ProBake offers a comprehensive range of pasta machines, including extruders, sheeters, and dryers. Their equipment is known for its reliability, flexibility, and ability to produce a wide variety of pasta shapes.

Making connects pasta manufacturers with innovative production technology and world-leading specialists. Their equipment includes high-performance extruders, dryers, and dough handling systems, ensuring high-quality pasta production.

Tondefoodmachine provides a variety of pasta processing machines, including multifunctional pasta makers, dough rollers, and noodle machines. Their equipment is designed for both commercial and home use, offering competitive prices and durability.

Amisy Food Machine offers a wide range of pasta processing equipment, including automatic dumpling machines, noodle makers, and dough kneaders. Their machines are known for their high efficiency, ease of use, and versatility.

Chefsubito specializes in professional and semi-professional pasta processing equipment, including spiral kneaders, dough sheeters, and pasta machines. Their equipment is constructed with high-quality materials, ensuring durability and ease of use.

Proper maintenance of pasta processing equipment is essential to ensure its longevity and optimal performance. Here are some tips for maintaining your equipment:

- Daily Cleaning: Clean the equipment thoroughly after each use to remove any dough residues and prevent bacterial growth.

- Deep Cleaning: Periodically perform a deep cleaning, disassembling the machine if necessary, to ensure all parts are free of buildup and contaminants.

- Moving Parts: Regularly lubricate moving parts to reduce friction and wear. Use food-grade lubricants to ensure safety and hygiene.

- Bearings and Gears: Pay special attention to bearings and gears, as these are critical components that require proper lubrication to function smoothly.

- Routine Inspections: Conduct routine inspections to identify any signs of wear or damage. Address any issues promptly to prevent further damage and ensure the equipment operates efficiently.

- Professional Servicing: Schedule regular servicing by professional technicians to maintain the equipment's performance and extend its lifespan.

- Dry and Clean Environment: Store the equipment in a dry and clean environment to prevent rust and contamination.

- Proper Covering: Cover the equipment when not in use to protect it from dust and debris.

The pasta processing industry is continuously evolving, with new trends and innovations enhancing the efficiency and quality of pasta production. Some of the latest trends include:

Automation and digitalization are transforming the pasta processing industry, with advanced machines offering features such as programmable settings, remote monitoring, and data analytics. These innovations enhance precision, reduce manual labor, and improve overall efficiency.

Sustainability is becoming increasingly important in the food industry, and pasta production is no exception. Manufacturers are adopting eco-friendly practices, such as using energy-efficient equipment and reducing waste through better process control.

Modern pasta processing equipment is designed to offer greater customization and flexibility, allowing manufacturers to produce a wider range of pasta shapes and sizes. This trend is driven by consumer demand for unique and diverse pasta products.

Pasta processing equipment is increasingly being integrated with other food processing equipment, such as packaging machines and quality control systems. This integration streamlines the production process, reduces handling, and ensures consistent quality.

Pasta processing equipment is essential for producing high-quality pasta efficiently and consistently. From dough mixers and kneaders to extruders and dryers, each piece of equipment plays a crucial role in the pasta production process. By investing in high-quality machinery and maintaining it properly, manufacturers can ensure their pasta products meet the highest standards of quality and taste.

Whether you're a commercial pasta manufacturer or a home chef looking to elevate your pasta game, understanding the different types of pasta processing equipment and their functions is key to achieving success. Embrace the latest trends and innovations in the industry to stay ahead of the competition and meet the ever-evolving demands of consumers.

Explore the wide range of pasta processing equipment available from leading brands such as ProBake, Making, Tondefoodmachine, Amisy Food Machine, and Chefsubito, and take your pasta production to the next level. With the right equipment and knowledge, you can create delicious, high-quality pasta that delights customers and stands out in the market.

Ready to elevate your pasta production? Explore our comprehensive range of pasta processing equipment and find the perfect machines to suit your needs. Visit our website or contact our experts today to learn more and get started on your journey to pasta perfection

Pre :

Next :

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Production Line

Pasta Production Line

Ready to Get Started?