Chicken Feet Peeling Production Line

The chicken feet peeling production line is a professional system designed for efficient and high-output chicken feet processing. It is user-friendly and represents the most advanced domestic technology in chicken feet peeling equipment. We offer customization options to meet specific customer requirements.

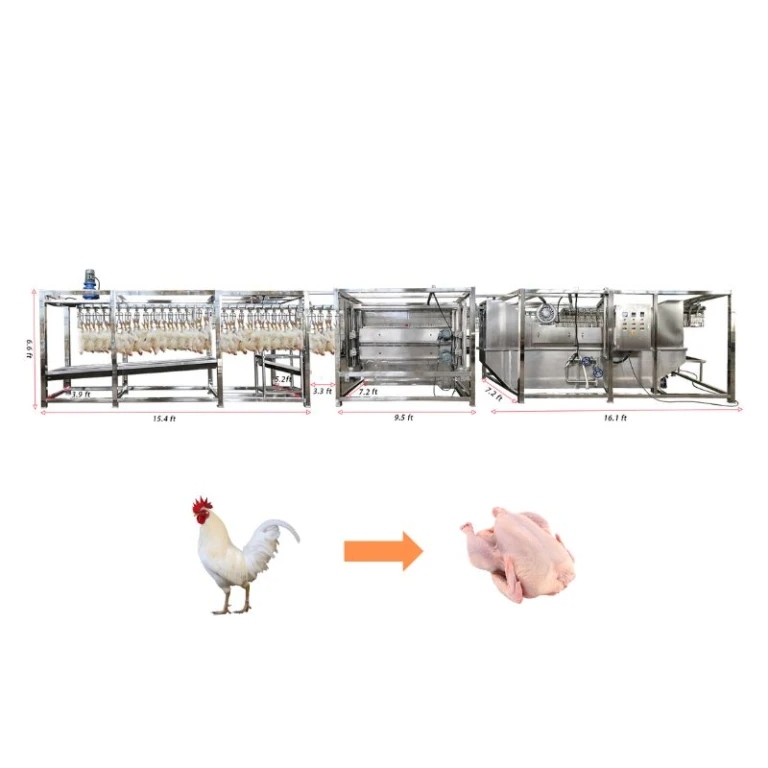

Chicken Feet Peeling Production Line Main Parts

Spiral type chicken feet blanching machine 2. Chicken Feet peeling machine 3. Spiral type auto feet pre-cooling

The flowchart of the chicken feet peeling production line is as follow Conveying--Chicken feet --Conveying--Blanching --Peeling --Pre-cooling

1. Put the chicken paw on the conveyor and transport the chicken feet to the blanching machine

2. Blanching is a necessary part in processing the chicken feet, through disinfect and cook chicken feet, the chicken feet is easy topeeling and it also can protect its natural flavor from being broken.

3. Transport the chicken feet to the chicken feet peeling machine for peeling the skin via the conveyor.

4. The last step is also the core step is peeling, the chicken peeling machine can peeling the chicken feet skin and nail cleanly andthere is no damage to the chicken feet.

5. Spiral type auto feet pre-cooling machine-used for cooling chickens, in order to achieve the purpose of detoxification.

Chicken Feet Peeling Production Line Advantages

1. The machines are all made of the stainless steel, which makes the chicken feet hygiene.

2. Excellent product quality, easy to operate.

3. A variety of processing capacity for your choice, we can customize it for you.

4. Stable performance, low cost, and labor saving.

Must-read blogs for bosses