Industry Challenges in Chicken Processing

The poultry processing industry faces increasing demands for hygiene, efficiency, and production consistency. Traditional or semi-automatic processes struggle with:

🔴 High Labor Dependency – Manual operations for slaughtering, deboning, cutting, and packaging lead to higher labor costs and unstable efficiency.

🔴 Strict Food Safety Standards – Compliance with HACCP, ISO22000, USDA, and EU regulations requires precise control over each processing step.

🔴 Inefficient Production Capacity – Manual lines cannot meet the increasing demand for fast, large-scale, standardized production.

🔴 Inconsistent Product Quality – Poor process control results in unstable product quality, shelf life, and customer satisfaction.

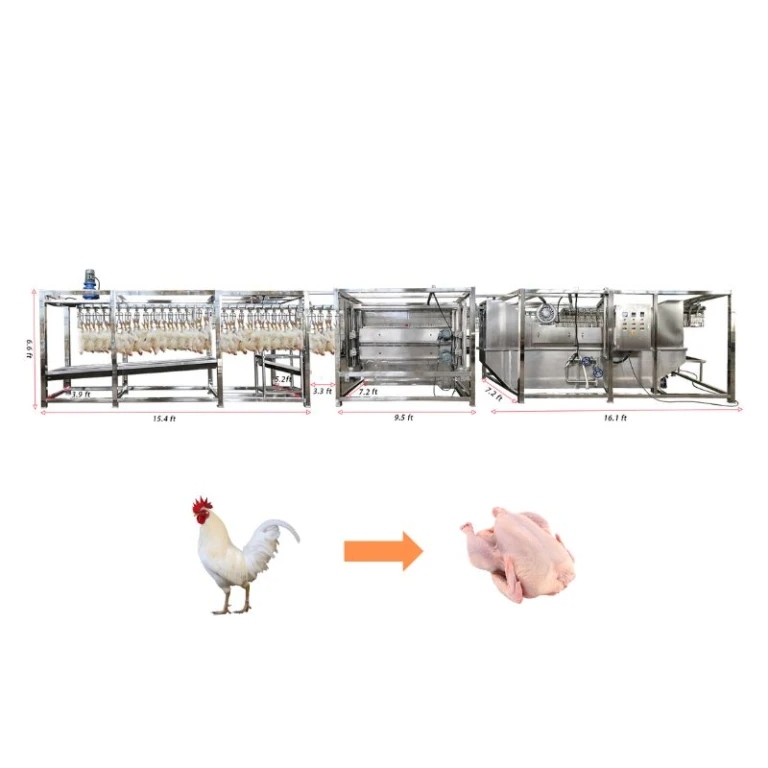

Our Solution: Fully Automated Chicken Processing Line

We provide integrated, fully automated chicken processing lines to help modern food factories achieve standardized, hygienic, and efficient production — from slaughtering to final packaging. Our solution ensures stable output, improved efficiency, and strict food safety compliance.

Core Processing Flow

Live Bird Reception → Stunning & Slaughtering → Scalding & Plucking → Evisceration → Chilling → Cutting / Portioning → Deboning → Trimming → Grading → Packaging → Cold Storage / Dispatch

✅ Streamlined factory layout for efficiency

✅ Minimized human contact for hygiene assurance

✅ Flexible configurations for whole chicken, parts, or further processed products

Applicable Products

Whole Chicken

Chicken Parts (Leg, Breast, Wing, Drumstick)

Boneless Chicken

Cut-up / Portion Packs

Frozen Processed Chicken Products

Key Advantages of Our Chicken Processing Line

① Automation for Productivity & Cost Reduction

Highly automated systems reduce labor by 60%+, increase production capacity, and ensure stable, efficient workflow.

② Strict Food Safety Compliance

Fully compliant with HACCP / ISO22000 / USDA / CE standards, ensuring hygiene, traceability, and regulatory approval for export.

③ Precision Processing for Product Consistency

Advanced cutting and portioning technologies deliver standardized sizes, weights, and appearances to meet market specifications.

④ Flexible Customization

Production lines are customized to fit your capacity, space, and product range — from small-scale plants to large industrial factories.

⑤ Energy-Saving & Low Maintenance

Efficient equipment design reduces water, energy, and maintenance costs for long-term operational savings.

Proven Results From Our Clients

| Before Automation | After Automation | Benefits Realized |

|---|---|---|

| High labor reliance | Labor reduced by 60%+ | Annual labor cost reduced by 30%+ |

| Low production capacity | Capacity increased 50%+ | More stable delivery & orders |

| Inconsistent product quality | Standardized output | Higher customer satisfaction |

| Food safety compliance risk | Fully compliant processes | Easier international export |

Why Choose Us?

✅ 20+ Years Poultry Processing Expertise

✅ 100+ Factory Installations Worldwide

✅ Tailor-Made Factory Solutions

✅ Comprehensive After-Sales Service & Support

✅ Fast Response, Reliable Delivery

Contact Us for Tailored Solutions & ROI Analysis

Transform your poultry processing factory for long-term success with our proven solutions.

Must-read blogs for bosses