The Ultimate Guide to Chicken Plucker Machines: A Comprehensive Look

In the modern poultry industry, efficiency and hygiene are paramount. Traditional manual plucking is not only time-consuming and labor-intensive but also prone to damage and bacterial contamination of the meat. To address these challenges, chicken plucker machines have emerged as essential equipment. This article will provide a comprehensive guide to chicken pluckers, helping you understand, choose, use, and maintain these modern poultry processing tools.

I. Understanding Chicken Plucker Principles and Types

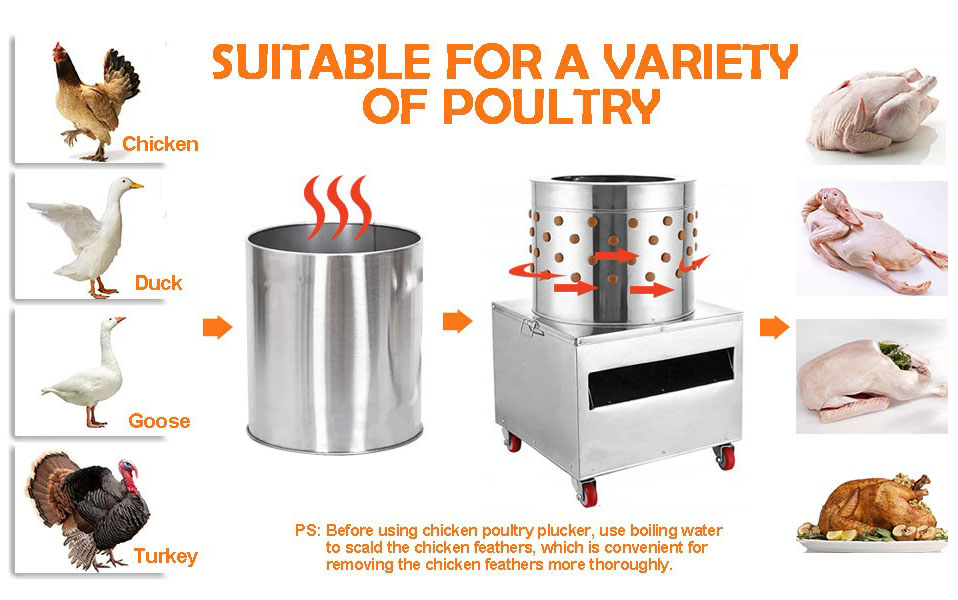

Chicken pluckers utilize various physical methods to quickly and efficiently remove feathers from poultry. Common operating principles include:

Rotary Plucker: These machines employ high-speed rotating rubber fingers or nylon brushes to frictionally detach feathers from the carcass.

Drum Plucker: Chicken carcasses are placed within a rotating drum containing rubber rods or brushes for feather removal.

Water Plucker: This method utilizes high-pressure water jets to wash away feathers in a water tank.

Vacuum Plucker: This technique uses suction to draw feathers from the carcass, creating a featherless result.

Each chicken plucker type has its advantages and disadvantages. Rotary pluckers are simple to operate but can damage meat. Drum pluckers offer high output but consume significant energy. Water pluckers boast efficiency but require substantial water resources. Vacuum pluckers are efficient but expensive.

II. The Chicken Plucker Buying Guide

Selecting the right chicken plucker requires considering multiple factors. Here are some key considerations:

Farm Size: Small farms might opt for manual rotary or drum pluckers, while larger operations need automated, high-capacity machines.

Chicken Breed: Different breeds have variations in size and feather density, influencing plucker selection.

Plucking Efficiency: Evaluate the machine's plucking speed, thoroughness, and potential for meat damage.

Safety: Prioritize reliable, user-friendly, and easily maintainable machines.

Budget: Consider your financial constraints and choose a machine with optimal value for money.

III. Essential Tips for Using Chicken Plucker Machines

Properly using a chicken plucker maximizes efficiency, extends machine life, and minimizes safety risks.

Preparation: Clean the machine thoroughly, inspect its condition, and ensure proper grounding of electrical cords.

Operating Steps:

Submerge the chicken carcass in warm water to soften feathers for easier removal.

Place the carcass in the plucker and operate it according to the machine's manual.

After plucking, rinse the carcass with clean water to eliminate any feather remnants.

Cautions:

Avoid overusing the machine to prevent motor overheating.

Regularly inspect the machine for wear and tear, replacing damaged components promptly.

Keep the machine clean to avoid oil and dust buildup.

IV. Maintaining Your Chicken Plucker for Optimal Performance

Regular maintenance extends machine lifespan and enhances plucking efficiency.

Daily Maintenance:

Clean the machine, especially the plucking drum or brushes, after each use.

Check the motor, transmission belt, and other parts for proper operation.

Apply lubricant to ensure smooth machine functioning.

Periodic Maintenance:

Monthly, assess the machine's internal cleanliness, removing accumulated dust and grease.

Inspect the rubber rods or brushes for wear, replacing them as necessary.

Check the motor, transmission belt, and other components for potential repair or replacement.

V. Safety Considerations with Chicken Plucker Machines

Safety is paramount when using chicken pluckers. The following guidelines must be adhered to:

Operators: Ensure that all operators receive proper training, understanding machine operation and safety procedures.

Protective Gear: Operators must wear safety helmets, gloves, and eye protection.

Electrical Safety: Verify proper grounding of electrical cords to prevent electrical shocks.

Mechanical Safety: Regularly inspect safety devices, including safety switches and emergency stop buttons, for proper functioning.

VI. The Future of Chicken Plucker Technology

Advancements in technology are driving the evolution of chicken pluckers towards greater automation and intelligence. Future generations of chicken pluckers will be even more efficient, safe, and environmentally friendly, featuring:

Smart Control: Integration of sensors and artificial intelligence for automated control, improving plucking efficiency and accuracy.

Green Technology: Utilizing energy-efficient materials and technologies to minimize energy consumption and emissions.

Multi-Functionality: Expanding beyond plucking to encompass cleaning, sanitation, and other operations, enhancing production efficiency.

VII. Applications of Chicken Plucker Machines

Chicken pluckers are indispensable equipment across various poultry-related operations, including:

Poultry Farms: Speeding up the plucking process, boosting work efficiency and farm profitability.

Slaughterhouses: Ensuring efficient plucking after slaughter, maintaining poultry meat quality and hygiene.

Processing Plants: Simplifying plucking before further processing, improving efficiency and product quality.

VIII. The Current State of the Chicken Plucker Industry

The global demand for chicken pluckers is on the rise due to increasing poultry consumption and advancements in farming techniques. The industry is witnessing the emergence of numerous chicken plucker manufacturers, offering diverse product options and constantly improving technical capabilities.

IX. Conclusion

Chicken pluckers are essential tools in the poultry industry, significantly enhancing production efficiency, reducing labor costs, and improving product quality. Selecting the right plucker, utilizing it correctly, and performing routine maintenance will maximize its benefits and contribute to the success of your poultry operation.

Must-read blogs for bosses