Chicken Cutting Machine Price: A Comprehensive Guide to Finding the Best Value

The chicken cutting machine has become an indispensable tool in the food processing industry, particularly for poultry processors and butchers. It offers significant advantages in terms of efficiency, precision, and hygiene, leading to increased production and reduced labor costs.

However, navigating the vast array of chicken cutting machines available can be overwhelming, especially when considering the price. This comprehensive guide aims to provide you with all the necessary information to understand chicken cutting machine prices, factors affecting costs, and how to find the best value for your specific needs.

I. Understanding the Basics: Types of Chicken Cutting Machines

Before delving into the price aspect, it's essential to understand the different types of chicken cutting machines available. These machines can be broadly categorized based on their functionalities:

1. Whole Chicken Cutting Machines:

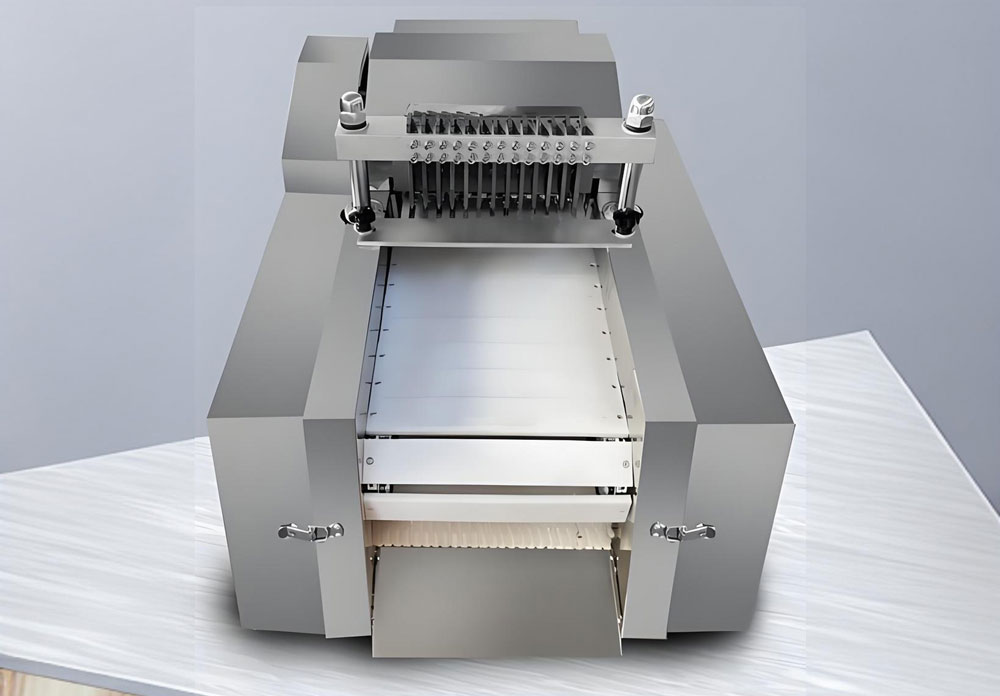

Automatic Whole Chicken Cutting Machines: These machines are designed to cut whole chickens into specific parts, such as breasts, wings, legs, and thighs, in a single operation. They typically feature a combination of cutting blades and conveyors for efficient and accurate portioning.

Semi-Automatic Whole Chicken Cutting Machines: These machines require some manual intervention, typically involving placing the chicken on a cutting platform and manually activating the cutting process. They offer a balance between automation and manual control, ideal for smaller-scale operations.

2. Chicken Breast Cutting Machines:

Automatic Chicken Breast Cutting Machines: These machines specialize in cutting chicken breasts into specific sizes and shapes, catering to the increasing demand for processed chicken breasts. They utilize specialized blades and conveyors for precise cuts and high-volume production.

Semi-Automatic Chicken Breast Cutting Machines: Similar to the whole chicken counterparts, these machines require some manual intervention, often involving placing the chicken breast on a cutting platform and activating the cutting process. They offer flexibility in handling different breast sizes and shapes.

3. Chicken Leg Cutting Machines:

Automatic Chicken Leg Cutting Machines: These machines are specifically designed for cutting chicken legs into desired portions, such as drumsticks and thighs. They employ specialized blades and conveyors for precise cuts and high-volume production.

Semi-Automatic Chicken Leg Cutting Machines: These machines require some manual intervention, usually involving placing the chicken leg on a cutting platform and activating the cutting process. They are ideal for smaller-scale operations and handling different leg sizes.

II. Factors Influencing Chicken Cutting Machine Price:

The price of a chicken cutting machine is influenced by a variety of factors, impacting the overall cost:

1. Machine Size and Capacity:

Larger machines with higher capacity generally command higher prices. These machines are capable of processing a greater volume of chicken per hour, justifying the higher cost for large-scale operations.

Smaller machines with lower capacity are often more affordable and suitable for smaller operations or businesses with lower processing volumes.

2. Automation Level:

Fully automatic machines, which require minimal manual intervention, are generally more expensive than semi-automatic machines. Automation reduces labor costs and increases production efficiency, justifying the higher price tag for larger operations seeking maximum productivity.

Semi-automatic machines, which require some manual handling, are typically more affordable but may require more labor and have lower production rates.

3. Cutting Technology and Precision:

Machines with advanced cutting technology, such as laser cutting or ultrasonic cutting, are generally more expensive than those with traditional blade cutting mechanisms. Advanced technologies offer greater precision, minimize waste, and produce higher-quality cuts, justifying the higher investment.

Machines with basic blade cutting mechanisms are typically more affordable and suitable for basic cutting operations.

4. Machine Features and Functionality:

Features like automatic weight control, conveyor belt speed adjustment, and built-in safety features can increase the overall cost of the machine. These features enhance efficiency, safety, and ease of operation, justifying the added expense for businesses seeking advanced functionality.

Basic machines with fewer features are typically more affordable and suitable for operations with basic cutting requirements.

5. Brand and Reputation:

Reputable brands known for their quality, durability, and reliability often have higher prices. Investing in a machine from a reputable brand can provide peace of mind regarding performance, longevity, and after-sales support.

Lesser-known brands or manufacturers may offer more affordable options but might lack the same level of reputation, support, and warranty.

6. Material and Construction Quality:

Machines made with high-quality materials, such as stainless steel, are typically more expensive but offer better durability, hygiene, and resistance to corrosion. These qualities are essential for food processing environments, ensuring long-term performance and meeting food safety standards.

Machines made with less durable materials may be more affordable but might be susceptible to wear and tear, leading to potential breakdowns and higher maintenance costs.

III. Typical Price Ranges for Chicken Cutting Machines:

The price of chicken cutting machines can vary significantly depending on the factors mentioned above. Here's a general price range for different types of machines:

Whole Chicken Cutting Machines:

Semi-Automatic: $5,000 - $20,000

Automatic: $20,000 - $100,000 or more

Chicken Breast Cutting Machines:

Semi-Automatic: $3,000 - $15,000

Automatic: $10,000 - $50,000 or more

Chicken Leg Cutting Machines:

Semi-Automatic: $2,000 - $10,000

Automatic: $5,000 - $30,000 or more

IV. Finding the Best Value: Tips for Making a Smart Purchase

Finding the best value for your chicken cutting machine requires careful consideration of your specific needs and budget. Here are some key tips:

1. Define Your Needs:

Processing volume: Estimate your expected chicken processing volume to determine the machine's capacity you need.

Cutting requirements: Identify the specific cuts you need and whether automation is essential.

Budget: Set a realistic budget and explore machines within your price range.

2. Research and Compare:

Online research: Explore reputable websites and online marketplaces for chicken cutting machines.

Read reviews: Gather insights from user reviews to understand machine performance, reliability, and customer satisfaction.

Compare features and specifications: Compare different models based on features, technology, and overall value proposition.

3. Contact Manufacturers and Suppliers:

Request quotes: Contact several manufacturers and suppliers to obtain detailed quotes and specifications for specific machines.

Inquire about warranty and after-sales support: Understand warranty coverage and the availability of technical support to ensure long-term peace of mind.

4. Consider Used Machines:

Explore used machine options: Used machines can offer significant cost savings, but thorough inspection and verification are crucial.

Check machine history: Inquire about the machine's maintenance history and any potential issues.

Seek expert advice: Consult with a qualified technician for a professional assessment.

5. Focus on Long-Term Value:

Consider the cost of operation: Factor in the cost of maintenance, repairs, and spare parts into your overall cost analysis.

Prioritize quality and reliability: Invest in a machine with a solid reputation for durability and performance to minimize long-term expenses and ensure consistent production.

V. Case Studies: Real-World Examples of Chicken Cutting Machines in Action

To further understand the value proposition of chicken cutting machines, let's explore a few real-world examples:

Case Study 1: Small-Scale Poultry Farm

A small-scale poultry farm, processing around 100 chickens per week, opted for a semi-automatic whole chicken cutting machine. The machine's affordability and ease of use allowed them to significantly reduce manual labor and improve cutting efficiency, boosting their overall output.

Case Study 2: Large-Scale Processing Plant:

A large-scale poultry processing plant, processing thousands of chickens daily, opted for a fully automatic chicken breast cutting machine. The machine's high capacity and automation capabilities allowed them to increase production significantly, reducing labor costs and meeting the increasing demand for processed chicken breasts.

Case Study 3: Independent Butcher Shop:

An independent butcher shop, seeking to improve its chicken processing efficiency and hygiene, invested in a semi-automatic chicken leg cutting machine. The machine's precision and hygiene standards allowed them to offer customers high-quality, consistent cuts, improving their reputation and increasing customer satisfaction.

VI. Conclusion: Investing in the Right Chicken Cutting Machine

Choosing the right chicken cutting machine requires careful consideration of your specific needs, budget, and long-term goals. By understanding the different types of machines, factors influencing price, and tips for finding the best value, you can make an informed decision that optimizes efficiency, productivity, and profitability for your business.

Remember, investing in a quality chicken cutting machine is an investment in the future of your business, ensuring consistent production, improved hygiene, and customer satisfaction, leading to long-term success.

Must-Read Blogs For Chain Restaurants Owner

Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line

Ready to Get Started?