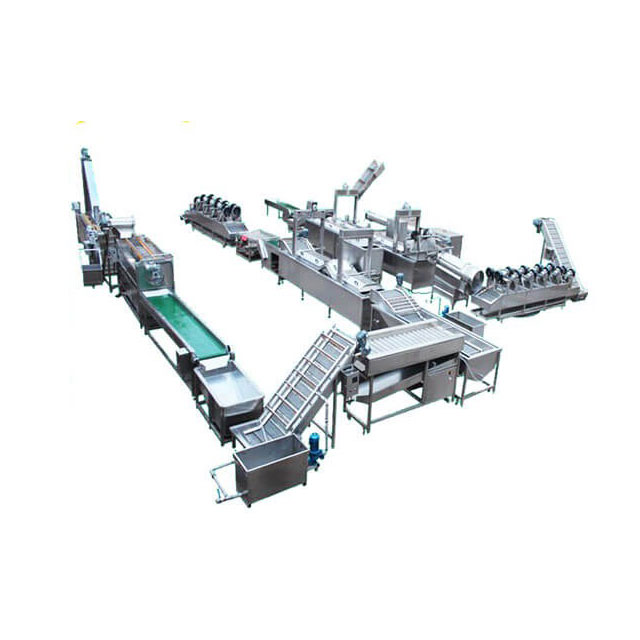

Introduction of Small Scale Frozen French Fries Production Line

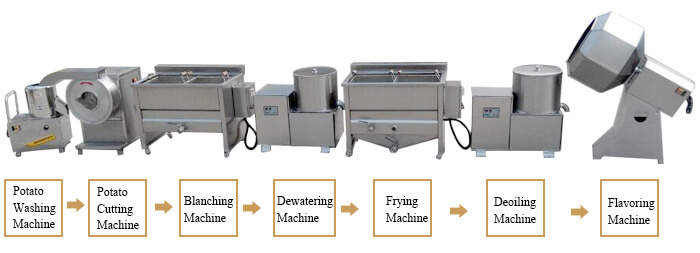

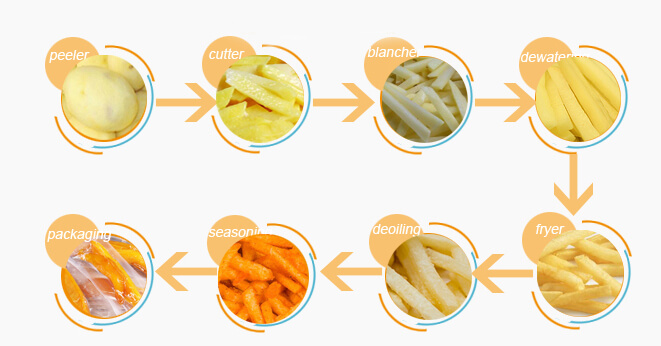

The Processing Flow of French Fries Making line

Potatoes -Washing and Peeling -Cutting-Blanching- Dewatering -Frying- Deoling - Seasoning- Freezing- Packing

Main French Fries Making Machines

1. Washing and peeling machine: cleaning and peeling process at one time

2. Cutting machine: cut into strip, flake and julienne shapes, adjustable cutting size3. Blanching machine: do rinsing and color protection of the cut potato chips4. De-watering machine: remove the water from the potato chips,

5. Frying machine: frying chips

6. De-oiling machine: remove the oil from the potato chips

7. Fast Frozen machine: to freeze the french fries.

8. Packing machine: packing the frozen french fires

What should be done by you to build your french friesmanufacturing factory?

1. A working shop, basic plant for manufacture (including the embedded parts), all necessary concrete etcmating facility.

2. Pipelines, valve, flange, and outer net parts expected for the pipelines of the manufacturing plant

3. Inside and outside lighting facility

4. Air Ventilation and air-conditioner facility

5. Electricity lines connect with the manufacturing plant and the electricity wire connecting6. Softened water cooling tower, circulating water pump, and the water pool7. The plant used to supply the water, electricity, compressed air facility and lab facility for testing8.Transport, insurance, uploading services.

9. Lifting facility

10. Fire fighting facility

Must-read blogs for bosses

- Why Customized Food Production Lines Are the Ultimate Game-Changer for Small and Medium-Sized Food E