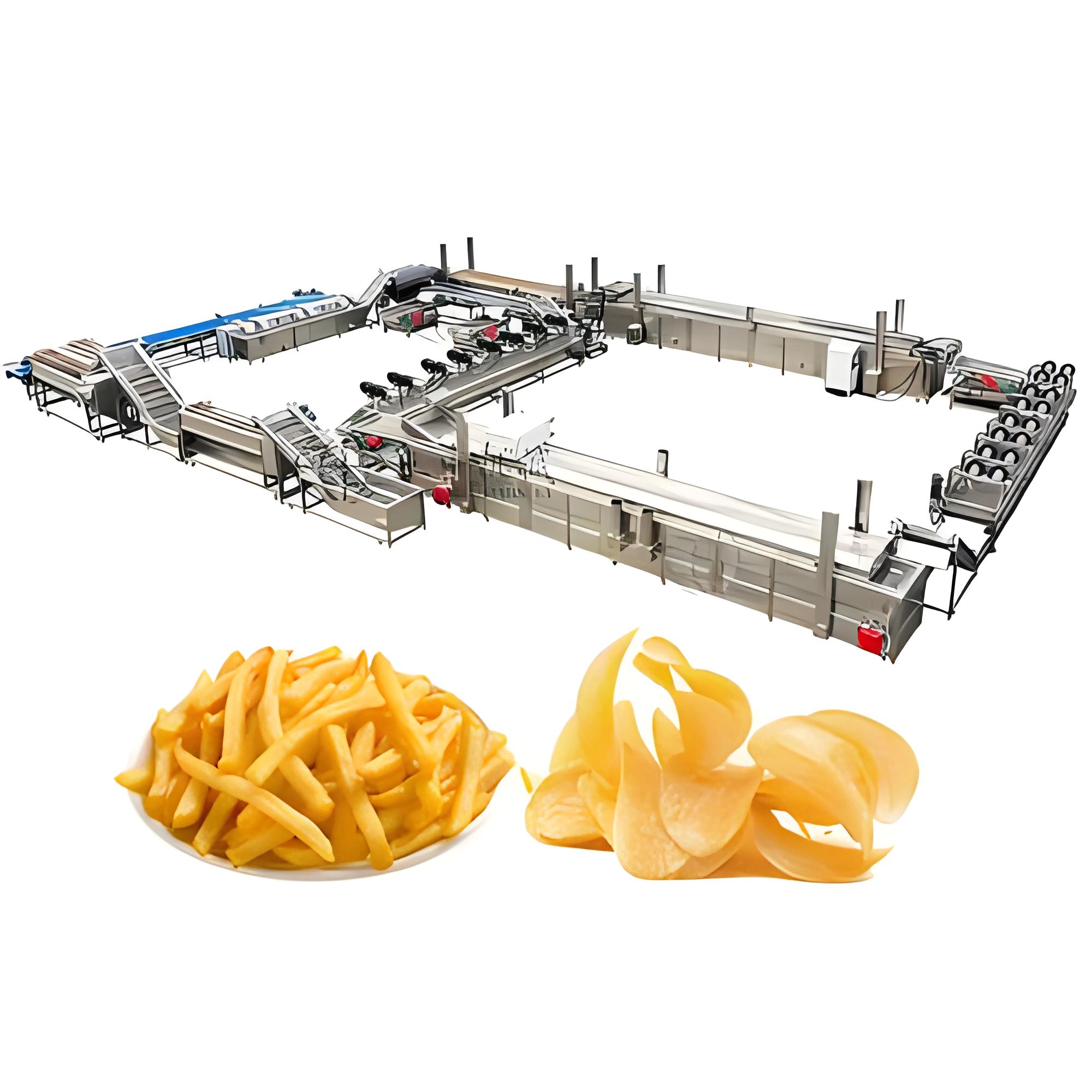

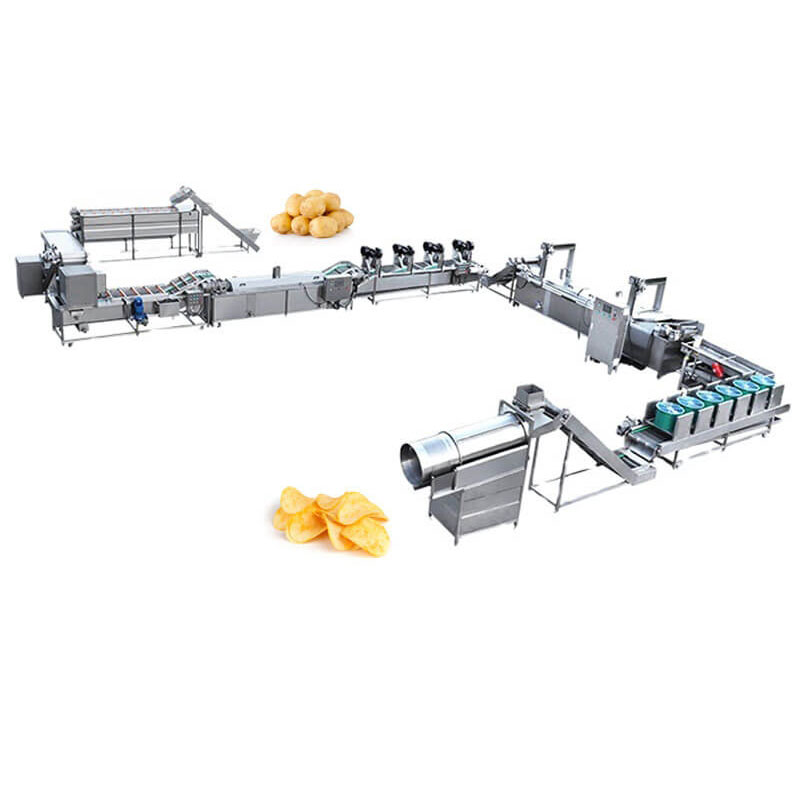

Our Fully Automatic French Fries Production Line is designed for industrial potato processing plants, frozen food manufacturers, catering supply factories, and large-scale agricultural product processors. The entire line integrates washing, peeling, cutting, blanching, dewatering, frying, deoiling, seasoning, freezing (optional), and packaging into a continuous and highly automated workflow.

Built with SUS304/316 food-grade stainless steel, smart PLC control, and optimized energy-saving systems, this production line delivers stable output, consistent product quality, and significantly reduced labor costs.

Production capacity available: 100 kg/h – 2,000 kg/h.

This solution ensures long-term profitability with low maintenance requirements, reduced oil and energy consumption, and full compliance with HACCP, ISO22000, and CE international food safety standards.

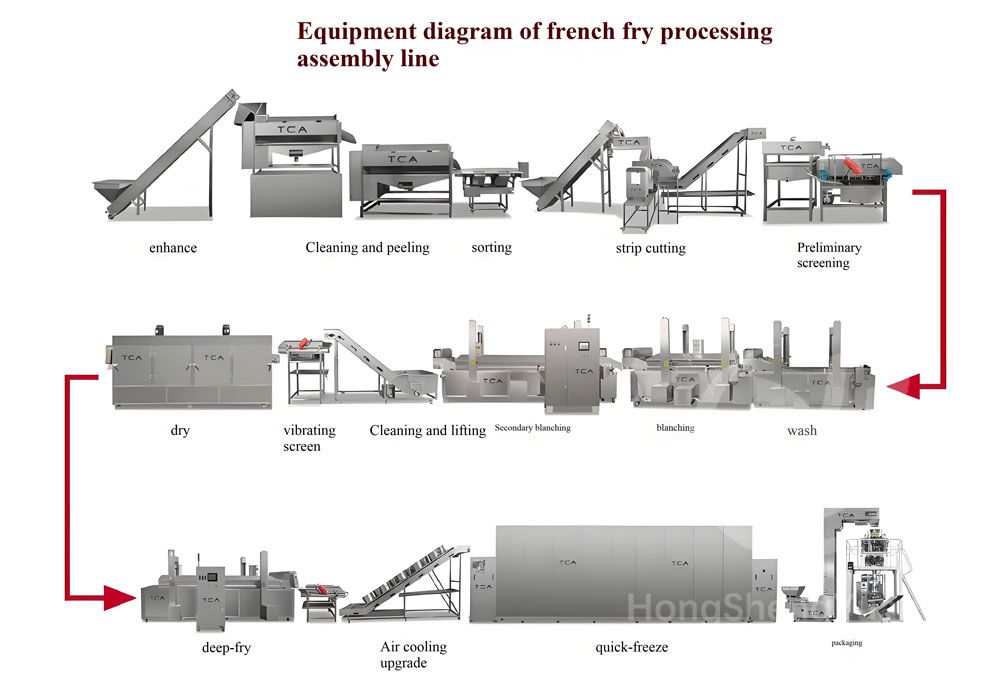

Process Flow (Fried Potato Chips & French Fries Line)

| Step | Process | Description |

|---|---|---|

| 1 | Feeding | Lifting raw potatoes to the peeler |

| 2 | Washing & Peeling | Continuous removal of mud, skin and impurities |

| 3 | Sorting | Eliminating defective potatoes |

| 4 | Feeding to Cutter | Transporting cleaned potatoes to cutter |

| 5 | Cutting | Slicing into chips or cutting into fries |

| 6 | Washing | Removing starch to prevent sticking |

| 7 | Blanching | Color protection and enzyme deactivation |

| 8 | Cooling | Lowering temperature after blanching |

| 9 | Dewatering | Air drying surface moisture |

| 10 | Frying | Continuous frying for crisp texture |

| 11 | De-oiling | Removing excess oil |

| 12 | Seasoning | Uniform coating of flavors |

| 13 | Cooling & Sorting | Cooling final product and removing defects |

| 14 | Packaging | Automatic weighing and sealing |

Process Flow (Frozen French Fries Line)

(Differences highlighted)

| Step | Process | Notes |

|---|---|---|

| 1–9 | Same as fried line | Washing → Peeling → Cutting → Washing → Blanching → Cooling → Dewatering |

| 10 | Par-Frying (Optional) | Light frying to form structure |

| 11 | De-oiling | Removing excess oil |

| 12 | Transfer | Conveying to freezing system |

| 13 | IQF Freezing | −35°C to −40°C individually quick freezing |

| 14 | Packaging | Frozen french fries packaging |

Equipment Functions (Integrated & Optimized Table)

| Machine Name | Function Description |

|---|---|

| Lifting Conveyor | Feeding potatoes into next stage automatically |

| Washing & Peeling Machine | Continuous washing, mud removal, skin removal |

| Sorting Conveyor | Manual selection of defects, improving product quality |

| Slicing / Cutting Machine | Adjustable thickness for chips and fries (6×6mm, 7×7mm, 9×9mm) |

| Washing Line | Removes starch to avoid sticking and uneven frying |

| Blanching Machine | Color protection, enzyme deactivation, improved texture |

| Cooling Line | Stabilizes potato structure before frying |

| Air Dewatering Machine | Removes surface moisture, reduces oil absorption |

| Continuous Frying Machine | Accurate temperature control, automatic oil filtration |

| De-oiling Machine | Centrifugal or vibration de-oiling |

| Seasoning Drum | Powder or liquid flavor coating |

| Cooling & Sorting Line | Air cooling and defect removal |

| Packaging Machine | Automatic weighing, nitrogen filling, sealing |

| IQF Tunnel Freezer (Optional) | Fast freezing, non-stick belt, keeps color and shape |

Technical Parameters & Models

Available Capacity Options

| Model | Output Capacity | Suitable For |

|---|---|---|

| PC-100 | 100–200 kg/h | Small factories / startups |

| PC-300 | 300–500 kg/h | Medium-size plants |

| PC-500 | 500–1000 kg/h | Large snack manufacturers |

| PC-1000 | 1000–2000 kg/h | Industrial mass production |

| PC-2000 | 2000–3000 kg/h | Fully automatic large-scale production |

Core Equipment Specifications (Sample Parameters)

(Numbers can match your company’s real models)

| Equipment | Power (kW) | Voltage (V/Hz) | Dimensions (mm) |

|---|---|---|---|

| Lifting Conveyor | 0.75 | 380/50 | 1500×1800×1500 |

| Washing & Peeling Machine | 4.75 | 380/50 | 3000×900×1500 |

| Sorting Conveyor | 0.75 | 380/50 | 4000×1000×900 |

| Cutting Machine | 1.5 | 380/50 | 1300×900×1500 |

| Bubble Washing Machine | 5.5 | 380/50 | 4000×1200×900 |

| Blanching Machine | 125 | 380/50 | 5000×1200×950 |

| Air Dewatering Machine | 15 | 380/50 | 500×1200×1400 |

| Electric Frying Line | 203 | 380/50 | 5000×1200×2400 |

| De-oiling Machine | 15 | 380/50 | 4000×1200×1500 |

| Cooling & Sorting Conveyor | 0.75 | 380/50 | 4000×1100×900 |

Key Advantages

✔ Fully Automatic & Continuous

Reduces labor cost and boosts productivity.

✔ Stable Quality Output

Consistent color, crispiness, and texture.

✔ Food-Grade Stainless Steel

Meets global hygiene standards (HACCP / ISO / CE).

✔ High Energy Efficiency

Optimized heating system, constant-temperature control, oil filtration recycling.

✔ Customizable Design

Shapes: chips, shoestring fries, crinkle-cut fries, thick-cut fries, wave chips.

✔ Turnkey Project Support

Plant layout, installation, commissioning, training, and after-sales service.

FAQs

Q1: What is the required factory size?

Depends on capacity; typical layouts: 200–800 m².

Q2: How much does a full French Fries Production Line cost?

Varies by capacity, configuration, and heating mode. (We can prepare a detailed quotation.)

Q3: Can you provide installation and training?

Yes, both on-site and remote support.

Q4: Do you offer a frozen French fries solution?

Yes, with IQF freezer and cold-chain packaging.

Ready to Receive Your Customized Production Plan?

We provide free consultations, equipment selection guidance, and factory layout design.

Contact us for quotations, technical drawings, and tailored solutions.

Must-read blogs for bosses