In the food industry, speed, precision, and compliance are core competencies. Traditional manual inspection methods are inefficient, costly, and prone to subjective errors, failing to meet the rigorous demands of modern food production. Businesses urgently need a smarter, more reliable solution to tackle increasingly complex food safety challenges.

This is where "HongShengYuanLin" comes in. We offer a revolutionary AI-driven food detection machine, specifically designed for B2B clients in food production, processing, catering, and retail. Our goal is to fundamentally transform your food safety management.

HongShengYuanLin's Core Advantages:

1. Lightning-Fast Detection, Real-time Control:

- Traditional Pain Point: Lengthy lab testing cycles lead to production delays, missed intervention opportunities, and potentially massive recall costs.

- HongShengYuanLin Advantage: Our AI system delivers sub-second detection with continuous online monitoring. Whether it's foreign objects, surface defects, color anomalies, or potential microbial indicators, issues are instantly detected and flagged before products move to the next stage. This means your production line will never halt, boosting efficiency multifold.

2. AI's Eagle Eye, Unparalleled Accuracy:

- Traditional Pain Point: Manual inspection is susceptible to human error, difficult to standardize, yields uncertain results, and carries high compliance risks.

- HongShengYuanLin Advantage: Powered by deep learning models trained on vast datasets and integrated with high-precision computer vision and spectral analysis technologies, "HongShengYuanLin" can identify subtle changes and potential risks invisible to the naked eye (e.g., early mold growth, pesticide residue traces, meat spoilage indicators). Every inspection adheres to a unified standard, providing objective, accurate, and traceable digital results, significantly reducing human error and compliance risks.

3. Significant Cost Savings, Optimized Resource Allocation:

- Traditional Pain Point: High costs associated with acquiring and maintaining specialized detection equipment, employing numerous expert personnel, and incurring losses from spoiled food and recalls due to undetected issues.

- HongShengYuanLin Advantage: Our automated detection substantially reduces the need for manual inspectors, lowering labor costs. A single unit can replace multiple traditional testing instruments, saving on equipment procurement and maintenance expenses. Crucially, by identifying and removing non-conforming products at the source, we can significantly reduce food waste and recall losses, directly converting costs into profit.

4. Seamless Integration, User-Friendly, Future-Proof:

- Traditional Pain Point: Complex integration of new technologies, cumbersome operations, and high training costs.

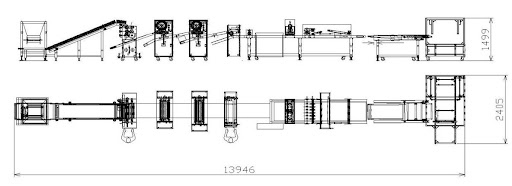

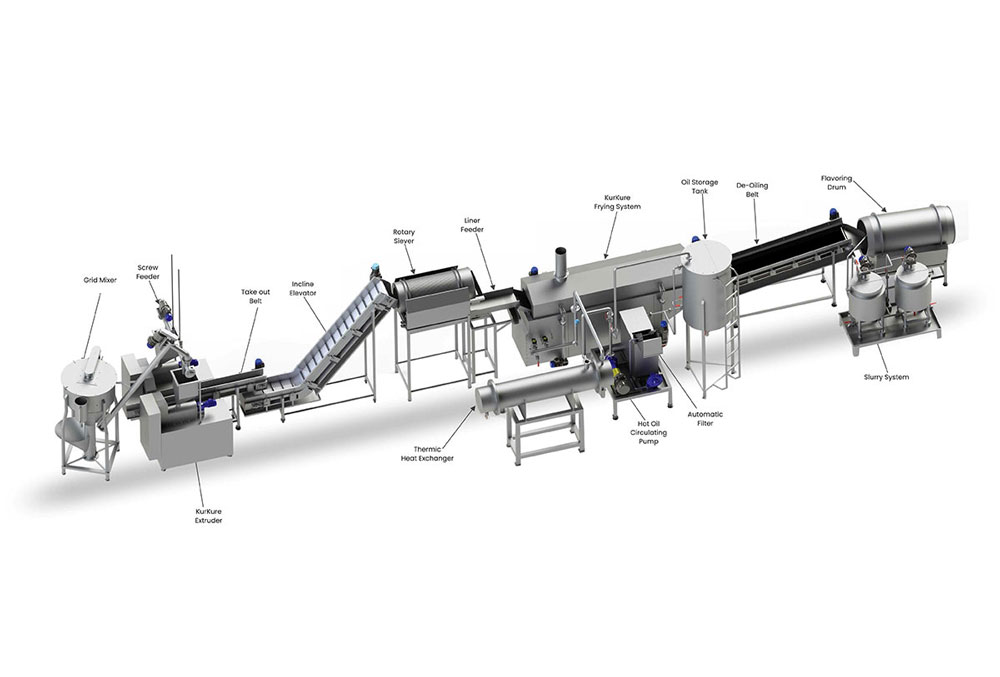

- HongShengYuanLin Advantage: "HongShengYuanLin" features a modular design that easily integrates into your existing production lines, offering various configurations to meet diverse scales and industry-specific needs. An intuitive user interface ensures that non-technical personnel can quickly operate it. Continuous data accumulation constantly refines our AI models, ensuring your food safety detection capabilities always stay at the forefront of the industry.

Applicable Scenarios:

- Food Production & Processing: Raw material incoming inspection, in-line quality control, finished product outgoing inspection.

- Catering Services: Ingredient freshness assessment, kitchen hygiene monitoring.

- Supermarkets & Retail: Fresh food quality identification, shelf-life management.

- Agricultural Primary Processing: Fruit and vegetable sorting, pest and disease identification.

Choosing "HongShengYuanLin" means choosing:

- Reliable Compliance Assurance: Meet increasingly stringent food safety regulations.

- Superior Product Quality: Enhance consumer trust in your products.

- Higher Operational Efficiency: Optimize production processes and reduce operating costs.

- Sustainable Business Growth: Minimize waste and support a greener food supply chain.

HongShengYuanLin is more than just a detection device; it's a strategic investment to boost your core competitiveness and achieve sustainable development.