Overview

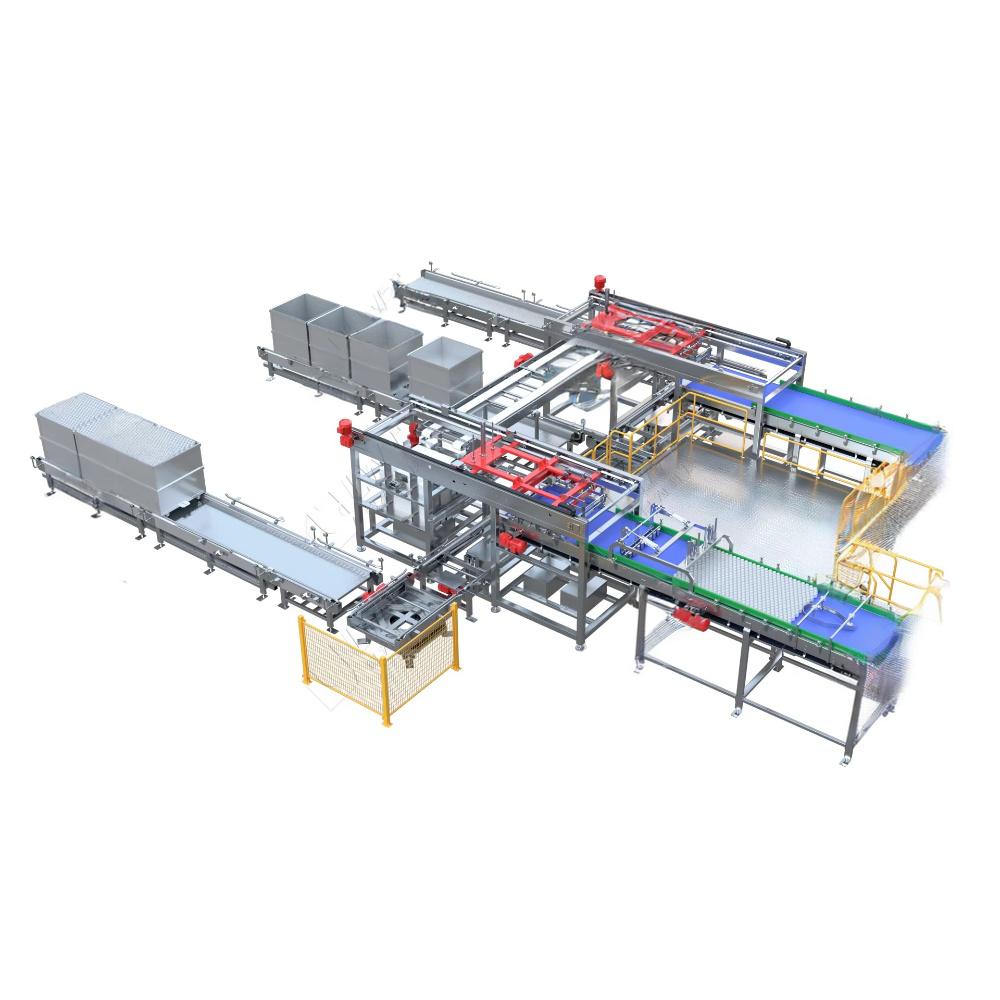

Our Automatic Fish Processing Line provides a fully integrated solution for the seafood industry — from raw fish handling to final packaging. Designed for maximum hygiene, yield optimization, and production efficiency, it ensures consistent product quality while reducing labor costs and operational downtime.

This turnkey solution is ideal for processing sardines, mackerel, tuna, salmon, anchovies, and other fish species, supporting production capacities from 500 kg/hour to 10 tons/hour.

Core Processing Flow

1. Raw Fish Receiving & Washing

Automatic conveyors and water flume systems transport fresh or frozen fish to the washing section, removing impurities and preparing for further processing.

2. Grading & Sorting

Precision grading machines classify fish by size, weight, or species, ensuring consistent filleting results and production balance.

3. De-heading & Gutting

High-speed automatic gutting and de-heading units handle different fish types efficiently, with minimal manual contact to meet HACCP and EU hygiene standards.

4. Filleting & Skinning

Automatic filleting machines deliver high yield and uniform cuts, while skinners ensure perfect removal of skin without damaging the meat texture.

5. Trimming & Inspection

Manual or camera-based inspection lines help ensure product quality and remove defective pieces before packing.

6. Cooking / Smoking / Steaming (Optional)

Depending on final product requirements, the line can integrate continuous steam cookers, smokers, or dryers.

7. Canning / Freezing / Packaging

For canned fish processing, automatic filling, seaming, sterilization, and labeling systems are integrated. For frozen products, the line can connect to IQF freezers and vacuum packaging machines.

Key Features

Hygienic Design: Made of 304/316L stainless steel, easy to clean and corrosion-resistant.

Automation Integration: PLC control system for synchronized operation and reduced labor intensity.

Customizable Layout: Modular design adaptable to client factory layouts and specific fish species.

Energy & Water Saving: Optimized process design reduces utility consumption and waste discharge.

Compliant with International Standards: Meets HACCP, CE, ISO 22000, and FDA requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Capacity | 500 kg/h – 10,000 kg/h |

| Fish Type | Sardine, Mackerel, Tuna, Salmon, Anchovy, etc. |

| Material | SUS304 / SUS316L Stainless Steel |

| Automation | Semi-automatic / Fully Automatic |

| Power Supply | 380V / 50Hz (Customizable) |

| Control System | Siemens PLC + Touch Screen |

| Warranty | 12–24 months |

Applications

Canned fish factories (tuna, sardine, mackerel)

Frozen seafood processing plants

Fish fillet and portioning facilities

Ready-to-eat fish snack or meal producers

Seafood export processing zones

Why Choose Us

Over 15 years of experience in fish and seafood processing machinery manufacturing

Turnkey plant design & installation including layout, training, and after-sales service

Proven performance in Southeast Asia, Africa, the Middle East, and South America

Flexible customization for production scale, packaging style, and fish species

Must-read blogs for bosses