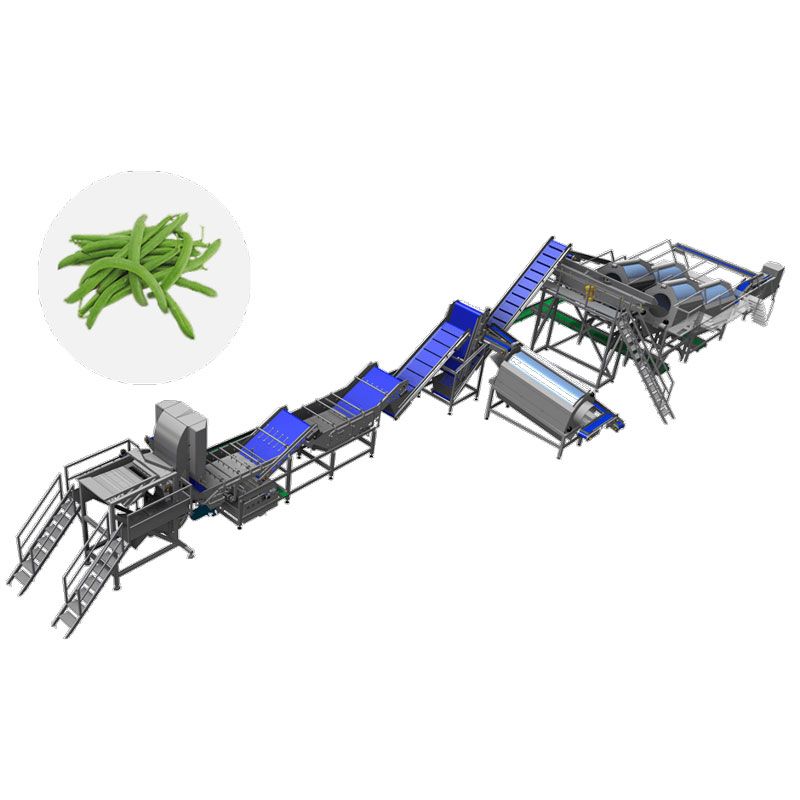

The Green Bean Canned Food Production Line is a complete automatic processing solution designed for vegetable canning plants. It integrates all stages of production—from sorting, washing, cutting, blanching, filling, sealing, sterilizing, cooling, to labeling and packaging—ensuring consistent product quality, extended shelf life, and compliance with international food safety standards such as HACCP, ISO22000, and FDA.

This line is suitable for processing green beans, kidney beans, peas, and mixed vegetables. With a modular design and customizable capacity options (1–10 tons per hour), it perfectly meets the needs of industrial-scale canning production.

Core Processing Flow

Raw Material Sorting and Washing

High-speed drum washer and bubble cleaning system remove mud and impurities.

Optical sorting machines ensure uniform color and quality selection.

Cutting and Blanching

Precision cutting equipment achieves consistent bean length.

Automatic blanching units deactivate enzymes, preserve color, and maintain texture.

Canning and Filling

Automatic can filling machines ensure accurate portioning.

Adjustable filling systems suitable for brine, sauce, or oil-based liquids.

Seaming and Sterilization

Vacuum seaming machines ensure tight sealing and prevent oxidation.

Continuous sterilizers and retort systems achieve microbial safety and product stability.

Cooling, Labeling, and Packaging

Rapid cooling tunnels prevent overcooking.

Automatic labeling and case-packing lines streamline logistics and export readiness.

Key Features and Advantages

Full Automation: PLC control system with real-time monitoring and fault diagnostics.

High Hygiene Standard: Contact parts made of food-grade SUS304/316 stainless steel.

Energy Efficiency: Optimized steam, water, and power consumption systems reduce operational costs.

Flexible Customization: Supports both tin cans and glass jars; adaptable for different can sizes (100g–1000g).

Easy Maintenance: Modular design for quick assembly, disassembly, and cleaning.

Global Compliance: Meets HACCP, CE, ISO, and FDA standards for export markets.

Applications

The Green Bean Canned Production Line is ideal for:

Vegetable Processing Plants

Canned Food Manufacturers

Export-oriented Food Companies

Central Kitchens and Agricultural Product Processors

It can also be integrated with mixed vegetable, corn, carrot, and mushroom canning systems to create a diversified product portfolio.

Technical Parameters (Example Configuration)

| Equipment | Function | Capacity | Material |

|---|---|---|---|

| Bubble Washer | Vegetable Cleaning | 1000–3000 kg/h | SUS304 |

| Cutting Machine | Size Uniforming | 1000–2500 kg/h | SUS304 |

| Blanching Unit | Enzyme Deactivation | 1000–5000 kg/h | SUS304 |

| Filling & Sealing Line | Automatic Canning | 30–120 cans/min | SUS304 |

| Sterilization Retort | Food Sterilizing | Custom | Carbon Steel + SUS304 |

| Labeling & Packaging Line | Final Packing | Custom | SUS304 |

Why Choose Us

As a leading Chinese manufacturer of canned food production lines, we provide turnkey solutions for various products including green beans, mushrooms, corn, fruit, tuna, and luncheon meat.

Our engineering team offers factory layout design, on-site installation, operator training, and technical support for global clients across Asia, the Middle East, Europe, and South America.

Must-read blogs for bosses