1. Overview

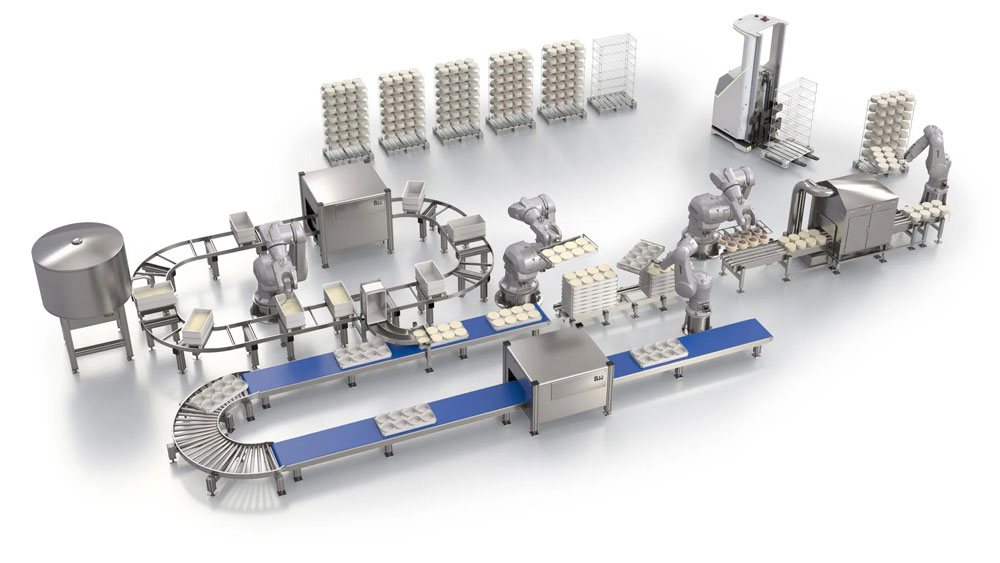

The Cheese Production Line is an advanced, fully automated system designed for the efficient production of various cheese types — including mozzarella, cheddar, processed cheese, cream cheese, feta, and other semi-hard and soft varieties.

It integrates milk standardization, pasteurization, coagulation, curd cutting, draining, molding, salting, and packaging into one streamlined process, ensuring consistent product quality, hygiene, and energy efficiency.

This line is ideal for industrial dairy plants, cheese manufacturers, and integrated food production facilities that require high capacity, stable operation, and compliance with international food safety standards.

2. Production Capacity

| Line Type | Output Range | Suitable For |

|---|---|---|

| Small Scale | 500–1,000 L/h | Pilot or artisan cheese producers |

| Medium Scale | 2,000–5,000 L/h | Mid-size dairy plants |

| Large Scale | 10,000–20,000 L/h | Industrial cheese factories |

(Custom layouts and capacity upgrades available.)

3. Process Flow

Milk Reception & Standardization

Fresh milk is filtered and standardized to achieve the desired fat and protein ratio.Pasteurization

Using a plate or tubular heat exchanger, milk is pasteurized at 72–78°C to ensure microbial safety.Coagulation

Milk is transferred into a cheese vat, enzymes (rennet) and cultures are added to form curd.Cutting & Stirring

Specialized knives cut curd into uniform cubes while gentle agitation helps whey separation.Cooking & Stretching (for Mozzarella)

Curd is heated and stretched to obtain elasticity and texture.Draining & Molding

Excess whey is drained; curd is shaped using automatic molding presses.Salting

The molded cheese passes through brine tanks or spray systems for flavor and preservation.Cooling & Packaging

Final products are cooled to 4°C and packaged by vacuum or MAP machines for freshness.

4. Core Equipment

| Equipment | Function | Key Features |

|---|---|---|

| Milk Storage Tank | Hold raw milk | SUS304 stainless steel, double-jacket cooling |

| Pasteurizer | Heat treat milk | PID-controlled temperature precision ±0.5°C |

| Cheese Vat | Curd formation | Automatic rennet dosing, variable-speed stirring |

| Curd Cutting Machine | Cut curds evenly | Stainless cutting grid, gentle agitation |

| Cheese Molding Press | Form cheese blocks | Hydraulic pressure system, adjustable molds |

| Brine Tank | Salting process | Food-grade polypropylene, automatic circulation |

| Cooling Tunnel | Rapid cooling | Chilled water system, energy-efficient |

| Packaging Machine | Final packaging | Vacuum sealing or nitrogen MAP options |

5. Technical Highlights

Fully Automated Control: Centralized PLC + HMI interface for parameter control and recipe management.

Precision Pasteurization: Stable temperature profiles ensure consistent microbial safety.

Energy-Efficient Design: Heat recovery between pasteurization and cooling cycles reduces energy use by up to 25%.

Hygienic Construction: All contact parts are made of SUS304/316 stainless steel with sanitary welds and CIP compatibility.

Modular Configuration: Adaptable for multiple cheese types (hard, semi-soft, spreadable).

Smart Monitoring: Real-time data tracking for temperature, pH, and flow control.

Low Maintenance: Quick-detach components and automatic cleaning system minimize downtime.

6. Product Range

Mozzarella

Cheddar

Gouda

Processed Cheese

Cream Cheese

Paneer

Feta & White Cheese

Ricotta

7. Optional Modules

Automatic Curd Handling System

Continuous Stretching and Molding Machine (for Mozzarella)

Whey Recovery & Concentration System

Salt Brine Recycling & Filtration Unit

Automatic CIP System

Inline pH and Fat Analyzer

Vacuum or Flow-Wrap Packaging Line

8. Technical Specifications (Example Line – 5,000 L/h)

| Item | Specification |

|---|---|

| Processing Capacity | 5,000 liters/hour |

| Power Requirement | 75 kW |

| Line Length | 30–45 meters |

| Material | SUS304 / SUS316L |

| Cooling Water | 5–10°C |

| Control System | Siemens PLC + HMI |

| Operating Temperature | 4–78°C |

| Automation Level | Fully automatic with data logging |

9. Quality & Compliance

Certified by CE / ISO9001 / HACCP / GMP

Meets EU food safety and dairy processing standards (EN1672-2)

Optional FDA and UL certification for North American markets

Complies with CIP/SIP sanitary design standards for easy cleaning

10. ROI & Operational Benefits

Labor Saving: Up to 60% reduction in manual handling

Yield Improvement: Consistent cheese quality, reduced waste (<1%)

Energy Efficiency: 20–25% lower operating cost vs. traditional systems

Return on Investment: Average ROI period of 18–24 months for mid-scale plants

11. Engineering & Support

Turnkey project service: design, manufacturing, installation, and training

2D/3D factory layout planning based on client’s space

Operator training and SOP documentation

24/7 online support and on-site maintenance

Global spare parts supply and remote diagnostics

12. Key Buyer Advantages

One-stop cheese processing solution from milk to final packaging

Modular design fits both new plants and existing dairy expansions

Reliable, low-maintenance, hygienic construction

Professional engineering support for global markets

Proven efficiency and profitability in continuous operation

13. Summary

The Cheese Production Line delivers a complete and hygienic solution for modern dairy factories.

With advanced automation, energy-efficient design, and precise process control, it ensures consistent quality and high yield for a wide range of cheese products.

It’s an excellent investment for any dairy plant seeking to modernize production, expand capacity, or enhance product diversity.

Must-read blogs for bosses