7 Maintenance Mistakes Food Factories Must Avoid — And How To Do It Right

In the fast-paced, high-stakes world of food manufacturing, equipment reliability is not a luxury — it's the backbone of business continuity, product quality, and food safety compliance. Yet, despite advances in automation and monitoring, more than 90% of food factories still fall into avoidable maintenance traps that cost them dearly.

This article explores 7 common but critical maintenance mistakes frequently observed across food processing plants worldwide. Each one seems small on the surface — but together, they can result in massive downtime, non-compliance penalties, equipment degradation, and lost revenue. We’ll not only explain what these mistakes are, but also give you actionable prevention strategies and show how specialized services like OEM support, global spare part access, and operator training can radically improve your plant’s resilience.

Mistake #1: Waiting Until Something Breaks

🚫 The Trap:

Reactive maintenance is still the default mode in many factories — machines are only serviced when a fault appears.

🔥 The Risk:

Unplanned downtime that halts production

Higher repair costs for advanced-stage damage

In some cases, complete asset loss requiring equipment replacement

✅ Pro Tip:

Implement a Preventive Maintenance (PM) program with scheduled inspections, part replacements, lubrication routines, and performance diagnostics. Don’t wait for symptoms — monitor based on run-time, vibration levels, temperature shifts, or production cycles.

💡 Our Service Support:

We help clients integrate predictive maintenance sensors (vibration, pressure, thermal) into critical machinery and offer PM kits tailored to specific equipment series. Our cloud-based remote monitoring helps identify early failure patterns—before downtime happens.

Mistake #2: Using Non-Food-Grade Lubricants or Cleaning Agents

🚫 The Trap:

To reduce procurement costs or due to lack of awareness, factories may use industrial lubricants or cleaning chemicals not rated for food contact areas.

🔥 The Risk:

Food contamination and consumer safety risks

Regulatory violations under FDA, HACCP, ISO 22000, or GMP

Costly recalls and reputational damage

✅ Pro Tip:

Only use NSF H1-certified food-grade lubricants and ensure all cleaning agents are compliant with food safety standards. Storage areas should clearly separate food-grade and non-food-grade substances. Operators must be trained in safe handling procedures.

💡 Our Service Support:

We provide complete lubrication charts and compliance guidelines with every equipment package, ensuring correct use. We also offer bundled consumables (lubricants, gaskets, cleaning kits) sourced directly from OEMs.

Mistake #3: Neglecting Operator Training and Equipment Handling Protocols

🚫 The Trap:

Operators handle machinery daily but may not fully understand its limits, sanitation needs, or maintenance requirements.

🔥 The Risk:

Misuse or unsafe startup/shutdown procedures

Internal component damage due to incorrect settings or overload

Increased wear due to improper cleaning or adjustment

✅ Pro Tip:

All staff interacting with production equipment — not just engineers — should undergo structured equipment training, including:

Start-up and shut-down protocols

Safe sanitation steps

Early failure signs (vibrations, noise, leaks)

Maintenance escalation procedures

💡 Our Service Support:

We offer on-site and virtual training covering over 50 equipment types, with modules tailored for different personnel levels — from operators to maintenance engineers. Custom SOP manuals and laminated quick-start guides can also be delivered.

Mistake #4: Poor or Nonexistent Maintenance Records

🚫 The Trap:

Maintenance actions often go undocumented, especially during busy shifts or crisis repairs.

🔥 The Risk:

Repeated failures go untraced

Inability to plan future preventive maintenance

Incomplete compliance records for audits

Difficulties in root cause analysis

✅ Pro Tip:

Adopt a digital maintenance log system. At minimum, records should include:

Date and time of service

Technician name

Issue description and resolution

Parts used and photos (before/after)

Consider moving toward a CMMS (Computerized Maintenance Management System) to centralize and automate record-keeping.

💡 Our Service Support:

We provide digital templates, logbooks, and CMMS integration services for our clients. Custom alerts can be set for part replacement cycles, technician assignments, and downtime tracking.

Mistake #5: Installing Aftermarket or Low-Quality Spare Parts

🚫 The Trap:

Sourcing “compatible” parts from non-OEM suppliers to cut costs or reduce wait times.

🔥 The Risk:

Incompatibility issues leading to damage or performance loss

Increased wear on adjacent parts

Voided warranties and food safety non-compliance

Shorter lifespan of the machine

✅ Pro Tip:

Use original OEM-certified parts only. They’re precision-matched to your machine’s tolerances and often include updated materials or designs that improve lifespan.

💡 Our Service Support:

We maintain a global inventory of high-turnover spare parts, with 48-hour express delivery for over 30 countries. Emergency replacement kits and critical wear parts are available in customizable packages.

Mistake #6: Overlooking Environmental Conditions

🚫 The Trap:

Focusing only on internal machine health while ignoring the factory environment — such as extreme humidity, temperature changes, or poor ventilation.

🔥 The Risk:

Electrical component failure due to condensation

Rusting of moving parts

Mold or bacterial buildup in processing zones

Sensor failures and calibration drift

✅ Pro Tip:

Control ambient conditions with:

Dehumidifiers or HVAC filters for moisture-sensitive rooms

Routine temperature mapping for cold zones

Anti-condensation enclosures for electronic panels

Cleaning protocols specific to climate-sensitive environments

💡 Our Service Support:

Our machinery is available with IP65-rated enclosures, anti-corrosion frames, and climate control modules. We also offer environmental risk audits and factory layout optimization.

Mistake #7: No Clear Ownership of Maintenance Tasks

🚫 The Trap:

When multiple departments share maintenance responsibilities, accountability disappears.

🔥 The Risk:

Missed inspections or inconsistent schedules

Delayed responses to faults

Finger-pointing and communication gaps during breakdowns

✅ Pro Tip:

Designate specific individuals or teams for each category of maintenance:

Daily cleaning: line operators

Weekly checks: on-site technician

Monthly diagnostics: senior maintenance engineer

Include measurable KPIs such as MTTR (mean time to repair), downtime frequency, and compliance completion rates.

💡 Our Service Support:

We assist clients in setting up custom maintenance teams, defining checklists, and conducting quarterly performance reviews. Our manuals also include responsibility maps for multi-department maintenance workflows.

🧯 Real-World Case Study: $85,000 Lost Due to Preventable Motor Failure

In early 2023, a frozen food company in Southeast Asia skipped regular lubrication for their filling line’s servo motor. The maintenance schedule — clearly outlined by the OEM — was ignored for 9 months. Eventually, the motor overheated during a weekend production rush, causing a shutdown across two shifts.

Total loss:

$50,000 in product loss (spoilage)

$20,000 in expedited motor replacement

$15,000 in overtime and penalties

All of this could have been prevented with a $15 lubricant and a 30-minute check.

🛠️ What Does a Proactive Maintenance Program Look Like?

An ideal maintenance system for food processing equipment should include:

| Element | Description |

|---|---|

| PM Scheduling | Based on run-time hours, environmental factors, or component fatigue modeling |

| Operator Training | Continuous learning plans with recertification every 12–18 months |

| CMMS System | Centralized, cloud-based maintenance tracking with alerts |

| OEM Support | Access to official parts, manuals, remote diagnostics, and hotline |

| Risk Audits | Bi-annual inspection of environment, wear zones, and sanitation practices |

| Performance KPIs | MTBF, MTTR, compliance rate, unscheduled downtime % |

✅ Final Takeaway: Maintenance is Not a Cost — It's an Investment

A robust maintenance program protects productivity, ensures compliance, and extends equipment life. Avoiding the 7 mistakes discussed in this article can help your plant:

Cut downtime by up to 40%

Reduce repair costs by 25–30%

Improve audit outcomes and food safety compliance

Increase the resale value of equipment

If you’re unsure where your factory stands, let us help you audit, restructure, and upgrade your maintenance strategy — backed by global OEM experience and real-world food industry insights.

Must-Read Blogs For Chain Restaurants Owner

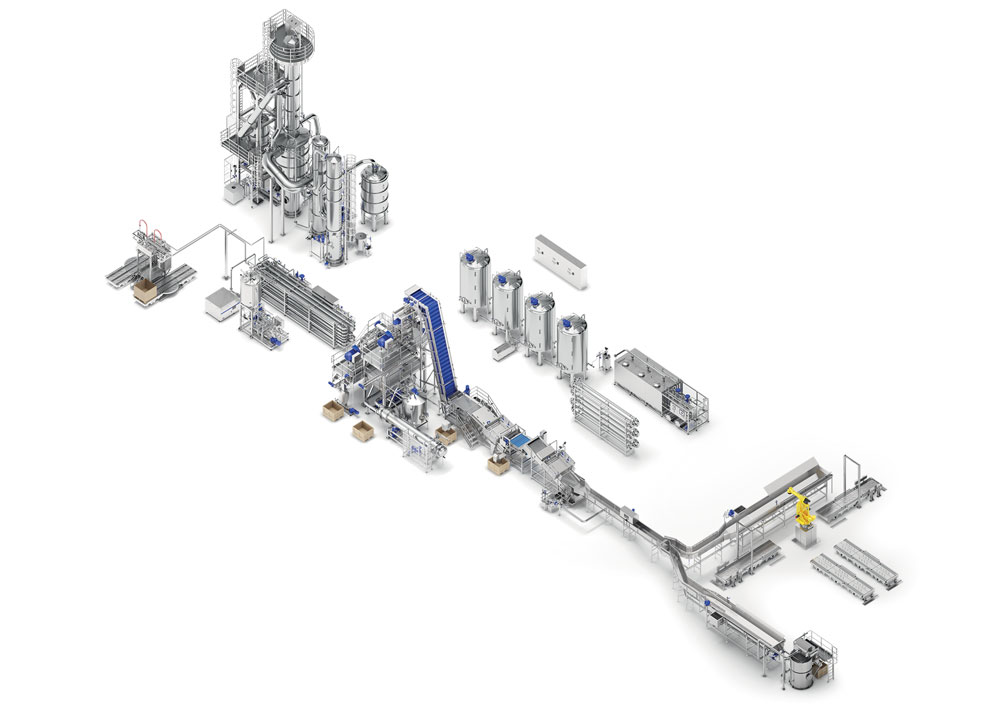

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?