125g Sardine Can Production Line - Chinese Manufacturer, Factory, Supplier

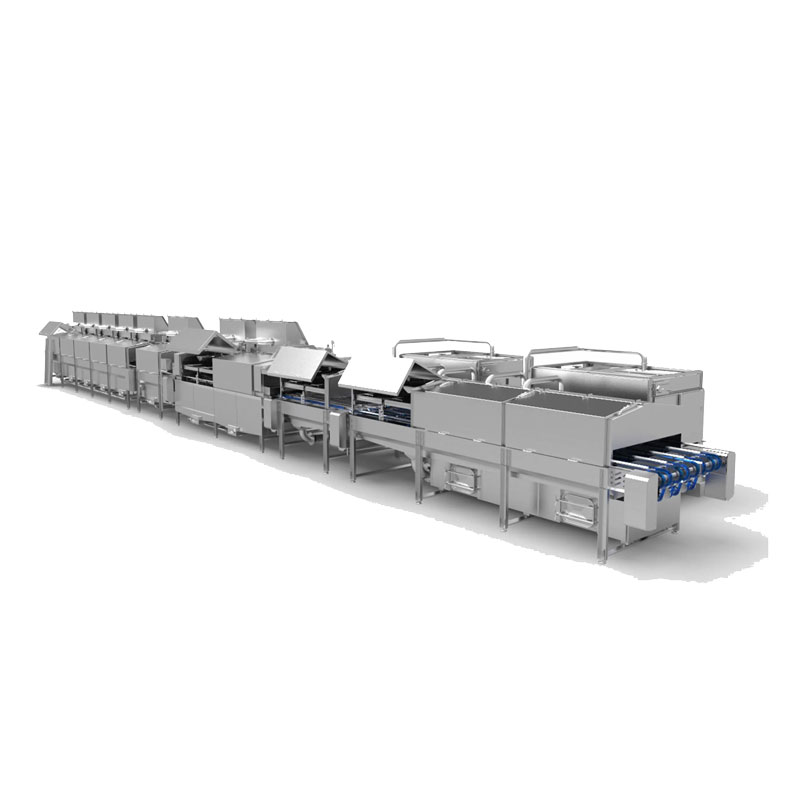

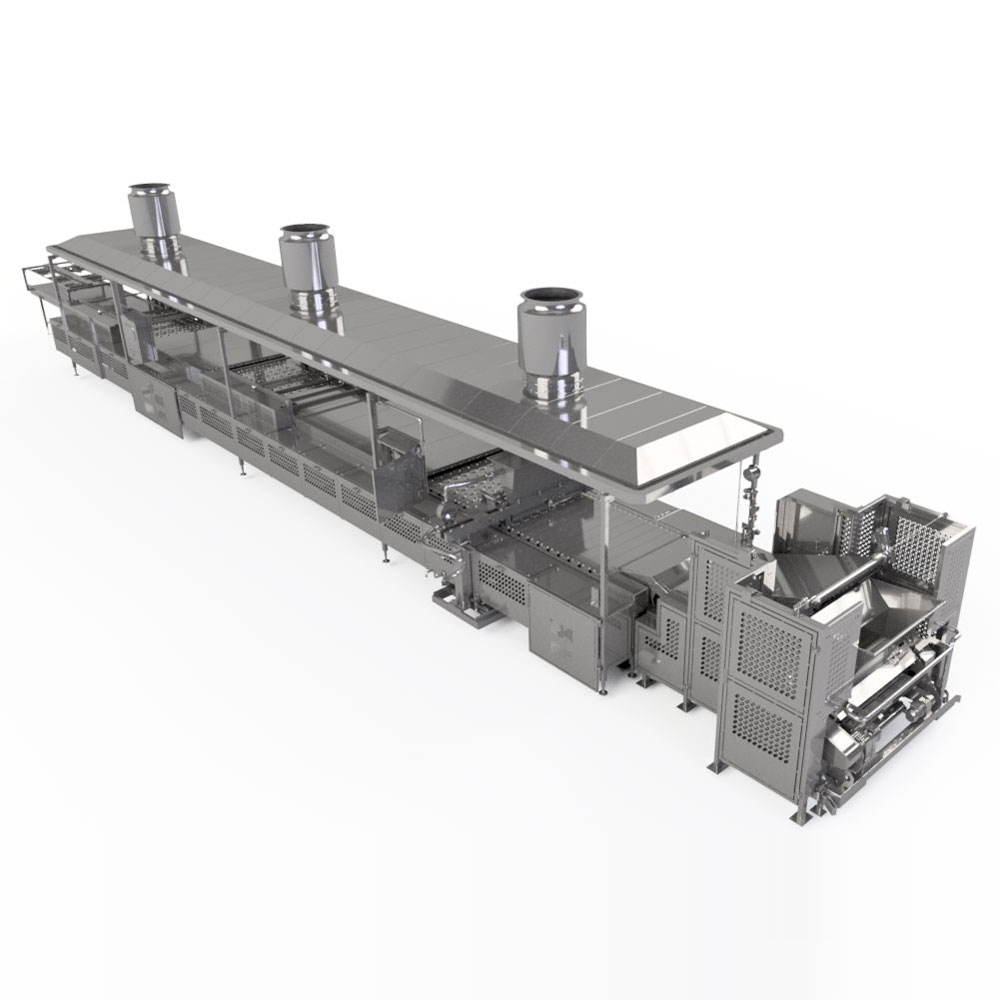

The 125g Sardine Can Production Line is a highly efficient and fully automated solution designed for modern seafood processing factories. This production line integrates sardine cleaning, cooking, filling, sealing, sterilization, and labeling into one continuous process, helping manufacturers achieve high output with superior product consistency and food safety.

Built from high-grade 304/316 stainless steel, the equipment ensures durability, easy maintenance, and full compliance with HACCP, ISO, and CE standards. The line is optimized for 125g tinplate or aluminum cans, widely used in export markets for sardines, mackerel, and tuna. The precise filling and vacuum sealing system maintains accurate portion control and prevents oxidation, preserving the natural flavor, texture, and nutrition of the fish.

The sardine canning process includes automatic fish loading, sauce or oil dosing, can filling, vacuum sealing, high-temperature sterilization, cooling, and labeling. Each section is automated and linked through a synchronized conveyor system, reducing manual handling and contamination risks. With production capacities ranging from 1000 to 15,000 cans per hour, the line can be customized to fit small, medium, or large-scale operations.

Advanced PLC and touchscreen controls provide real-time monitoring and parameter adjustments, ensuring stable production and minimal downtime. Optional systems such as can depalletizers, liquid filling machines, automatic retorts, visual inspection, and packaging units can be integrated to create a fully turnkey canning solution.

This 125g sardine can production line is ideal for seafood processors targeting Africa, the Middle East, Asia, and European export markets, where small-format canned sardines are in strong demand. The system’s high efficiency, energy-saving design, and precise temperature control make it an excellent investment for improving profitability and meeting strict international quality standards.

As a professional sardine canning equipment manufacturer in China, we provide complete engineering support — including layout design, installation, commissioning, and operator training. Whether you’re upgrading your existing factory or building a new production line, our technology helps you maximize yield, reduce labor costs, and expand your global market reach.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Shrimp Processing Line

Shrimp Processing Line Pizza Cone Equipment

Pizza Cone Equipment Chicken Slaughtering Machine

Chicken Slaughtering Machine Pancake Production Line

Pancake Production Line Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine