What Buyers Should Prepare Before Purchasing a Tomato Paste Production Line

Introduction

Tomato paste is a global commodity with wide applications in sauces, soups, ready-to-eat meals, and food service industries. With consumption rising steadily, many investors and manufacturers are considering purchasing a tomato paste production line to capture this demand. However, the process involves much more than buying equipment—it requires careful preparation to ensure efficiency, compliance, and profitability. This article explores the essential steps buyers should take before investing in a tomato paste production line.

Define Production Needs and Market Positioning

The first step in purchasing a production line is understanding your exact requirements.

Production capacity: Decide whether your target is 5 tons/hour, 20 tons/hour, or higher. This choice determines the size and complexity of your equipment.

Product types: Are you producing concentrated tomato paste only, or also tomato pulp, diced tomatoes, or tomato juice?

Packaging formats: Retail pouches, glass jars, sachets, or bulk aseptic drums—each format requires dedicated filling and packaging systems.

Market focus: Supplying B2B industrial buyers is different from targeting consumer retail markets. Your choice will influence equipment, packaging, and marketing strategies.

A clear product and market strategy ensures your investment aligns with business goals.

Factory Infrastructure and Compliance

Before the equipment arrives, ensure your factory meets the necessary conditions.

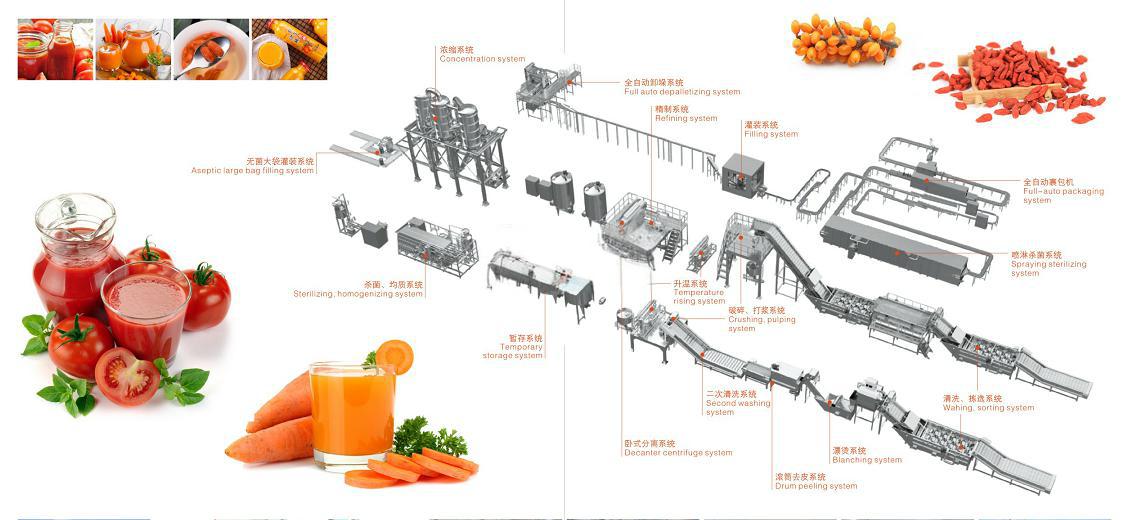

Factory layout: A tomato paste production line typically includes zones for raw material reception, washing, crushing, pulping, concentration, sterilization, aseptic filling, and storage. Each area must be separated to prevent cross-contamination.

Utilities: Reliable access to clean water, electricity, steam, and compressed air is essential. Any interruption can halt production.

Waste management: Install systems for wastewater treatment and byproduct handling in line with environmental regulations.

Certifications and standards: Compliance with HACCP, ISO22000, and GMP is critical. For export, FDA, CE, or HALAL certification may also be required.

Without these foundations, even the best equipment cannot deliver safe, high-quality products.

Equipment Planning and Supplier Selection

The equipment is the core of your investment. Selecting wisely saves cost and ensures long-term efficiency.

Key machinery: Washing machines, sorting conveyors, crushers, pulpers, vacuum evaporators, sterilizers, aseptic filling machines, and CIP (Clean-In-Place) systems.

Material quality: Equipment must be made of food-grade stainless steel (304/316) to withstand acidic tomato processing.

Automation: High automation improves consistency, reduces labor needs, and lowers operational costs.

Supplier evaluation: Look for suppliers with proven projects in tomato paste plants, strong after-sales service, and the ability to customize solutions.

A good supplier becomes a long-term partner, not just an equipment vendor.

Raw Material and Supply Chain Readiness

A production line is only as reliable as its raw material supply.

Sourcing: Secure long-term contracts with tomato farmers or cooperatives.

Harvest logistics: Tomatoes are perishable and must be processed quickly. Plan efficient harvesting and transport to minimize spoilage.

Seasonality: Decide whether to run seasonally (during harvest) or year-round by using stored tomato paste concentrate.

Securing a stable supply chain reduces downtime and ensures consistent production.

Workforce and Training

People are just as important as machines in running a food factory.

Skilled operators: Technicians and machine operators trained to handle processing equipment.

Quality control staff: Ensuring every batch meets food safety and consistency requirements.

Training programs: Continuous training on hygiene, equipment use, and emergency procedures.

Investing in a trained workforce reduces errors, waste, and safety risks.

Financial Planning and ROI

Purchasing a tomato paste production line is a significant financial commitment.

Capital expenditure (CAPEX): Includes land, construction, equipment purchase, and installation.

Operating expenses (OPEX): Covers raw materials, utilities, labor, maintenance, and logistics.

Cash flow: Plan for phased payments to suppliers, spare parts inventory, and operational reserves.

ROI strategies: Automation, lean production methods, and energy-efficient technologies lower long-term costs.

Accurate financial planning ensures sustainable profitability.

Trial Production and Market Entry

Before mass production, conduct a trial run.

Pilot testing: Small-batch runs validate line performance and product quality.

Packaging and branding: Design food-grade, attractive packaging suitable for your target market.

Distribution channels: Supermarkets, food service companies, and export markets each require tailored approaches.

Marketing: Use SEO, B2B trade platforms like Alibaba, and food trade exhibitions to connect with buyers.

A well-executed launch helps you build market credibility quickly.

Conclusion

Purchasing a tomato paste production line is more than an equipment decision—it is a strategic investment in infrastructure, compliance, raw materials, workforce, and branding. Buyers who prepare thoroughly can avoid costly delays, ensure smooth production, and secure a strong foothold in the global tomato processing industry. By following these steps, you can transform your factory into a profitable and competitive business.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?