How to Build a Food Factory: Step-by-Step Guide for Investors and Manufacturers

Introduction: Why Food Factory Setup Matters

The global food industry is one of the fastest-growing and most resilient sectors, driven by rising populations, changing lifestyles, and increasing demand for convenient, safe, and high-quality foods. For investors, entrepreneurs, and manufacturers, setting up a food factory presents a lucrative opportunity to tap into this demand. However, the process is highly complex—it requires careful planning, regulatory compliance, and significant capital investment. In this guide, we’ll walk through the step-by-step process of how to build a food factory, focusing on key considerations such as site selection, plant design, equipment, safety standards, and return on investment (ROI).

Market Research and Business Planning

Before laying a single brick, a clear market strategy is essential.

Define your product scope: Decide whether the factory will produce bakery items, beverages, meat products, frozen foods, sauces, or ready meals. Each category comes with its own processing technology, equipment, and compliance requirements.

Analyze demand and competition: Study consumer preferences, industry trends, and competitive landscapes. For instance, the plant-based food market is expanding rapidly, while demand for frozen ready meals is also increasing due to busy lifestyles.

Calculate ROI and payback period: Investors typically look for a payback within 3–5 years. Conduct a detailed financial feasibility analysis, including capital expenditures (CAPEX) and operational expenditures (OPEX).

Identify B2B vs. B2C opportunities: Determine whether you’ll supply semi-processed ingredients to food businesses or directly serve consumers with branded products. This decision influences your factory’s design and distribution channels.

A well-researched business plan minimizes risk and maximizes long-term profitability.

Site Selection and Infrastructure

Choosing the right location is critical to operational efficiency and cost management.

Proximity to raw materials: Meat processing plants should be near livestock farms, while fruit and vegetable factories benefit from proximity to agricultural hubs. This reduces logistics costs and ensures freshness.

Logistics accessibility: The factory should be well-connected to highways, ports, or airports for seamless inbound and outbound logistics.

Utility availability: Food production requires reliable access to water, electricity, gas, and sometimes steam. Interruptions can halt production and cause financial loss.

Compliance with zoning laws: Ensure that the site is legally permitted for industrial food manufacturing.

👉 Tip: Many governments provide tax incentives, subsidies, or land grants to encourage food manufacturing investments. Explore these options to reduce initial capital costs.

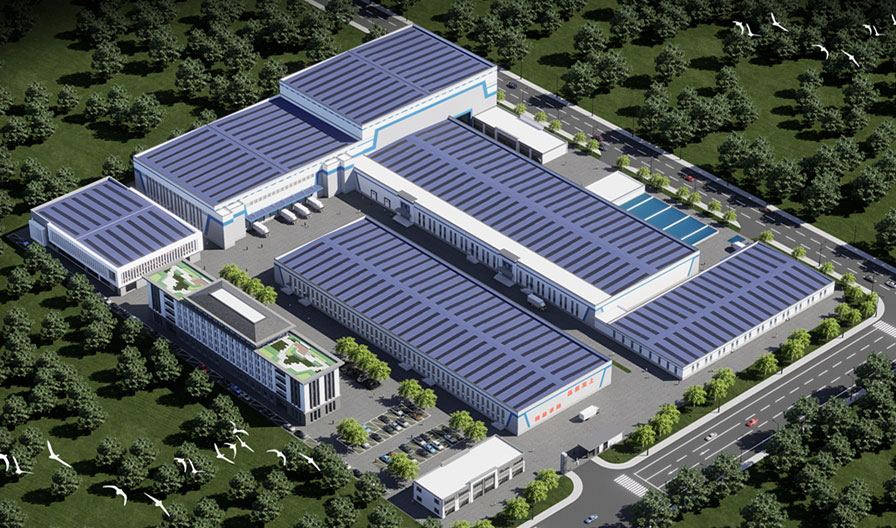

Factory Design and Layout

A well-designed factory ensures smooth operations and compliance with hygiene standards.

Functional zoning: Separate raw material reception, processing, packaging, cold storage, and quality control laboratories. This prevents contamination and ensures efficient workflows.

Flow optimization: The production line should follow a logical one-way flow, from raw input to finished goods, reducing the risk of cross-contamination.

Hygiene considerations: Use washable walls, anti-slip flooring, pest control systems, and proper ventilation to meet food safety standards.

Scalability: Design modular lines that can be expanded easily as demand grows.

A well-planned layout reduces inefficiencies and improves compliance with global certifications such as HACCP and ISO22000.

Equipment Selection and Technology

The heart of any food factory lies in its equipment. Choosing the right machinery determines production efficiency, quality, and compliance.

Core machines: Depending on your product type, these may include slicers, mixers, pasteurizers, fryers, bottling lines, or vacuum packaging machines.

Automation level: Higher automation reduces reliance on manual labor, minimizes errors, and increases consistency. Robotic arms and IoT-enabled sensors are increasingly common in modern food factories.

Maintenance and cleaning: Equipment should be designed for easy cleaning (CIP/SIP systems) to maintain hygiene and minimize downtime.

Supplier support: Work with reliable suppliers who offer installation, training, spare parts, and after-sales service.

Investing in advanced food processing equipment pays off in the long run through reduced waste, higher efficiency, and lower labor costs.

Food Safety and Quality Standards

Food safety is non-negotiable. Consumers and regulators demand the highest standards.

HACCP (Hazard Analysis and Critical Control Points): Identifies and monitors potential hazards in production.

ISO22000: Provides a comprehensive food safety management system.

GMP (Good Manufacturing Practices): Ensures hygiene and consistency in production processes.

Traceability systems: Track every batch from raw materials to distribution, ensuring accountability and quick recall if issues arise.

Failure to comply with these standards can result in severe legal penalties, product recalls, and loss of consumer trust. Building a strong food safety culture is essential for sustainable success.

Licensing, Certification, and Legal Approvals

Securing the necessary permits is a vital step before operations can begin.

Business license and food production license: Required to operate legally in most countries.

Special permits: Certain categories, such as dairy, meat, or infant formula, require additional approvals.

Environmental compliance: Wastewater treatment, solid waste management, and carbon emission regulations must be met.

Worker safety: Fire safety systems, emergency exits, and occupational health standards are mandatory.

Compliance not only keeps you on the right side of the law but also reassures clients and consumers of your reliability.

Workforce and Training

Behind every successful food factory is a well-trained workforce.

Skilled workers: Machine operators, technicians, and quality control specialists ensure smooth daily operations.

Management staff: Supply chain managers, procurement officers, and production planners optimize workflows.

Continuous training: Employees should undergo regular training in food hygiene, equipment handling, and safety protocols.

A competent team reduces errors, ensures consistency, and upholds your factory’s reputation.

Trial Production and Scaling Up

Before mass production, conduct pilot runs.

Small-batch testing: Run limited production to validate process efficiency and product quality.

Performance monitoring: Track yield rates, cycle times, and wastage.

Adjustments: Fine-tune production parameters before full-scale launch.

Trial production reduces risks and helps you optimize for commercial scale.

Branding and Market Entry

Even the best product won’t succeed without strong branding and distribution.

Packaging design: Use sustainable, food-safe materials with attractive branding that appeals to your target audience.

Distribution channels: Supply to supermarkets, restaurants, wholesalers, or directly to consumers through e-commerce platforms.

Digital marketing: Leverage SEO, LinkedIn, B2B platforms like Alibaba, and international trade fairs to attract global buyers.

Building a strong brand creates trust, which is critical in the competitive food industry.

Cost Management and ROI

Food factories require significant investment, making cost management essential.

CAPEX: Includes land, construction, equipment, and initial licensing.

OPEX: Covers raw materials, utilities, labor, maintenance, and logistics.

ROI optimization: Implement lean manufacturing, energy-efficient systems, and automation to reduce long-term costs.

Proper financial planning ensures steady growth and long-term profitability.

Future Trends in Food Manufacturing

The food industry is rapidly evolving, and staying ahead of trends is key.

Smart factories: IoT sensors, AI-driven quality control, and predictive maintenance enhance efficiency.

Sustainability: Eco-friendly packaging, renewable energy, and carbon-neutral production are increasingly important for global buyers.

Customization: Consumers are demanding plant-based alternatives, functional foods, and personalized nutrition.

Adapting to these trends positions your factory for long-term success in a competitive market.

Conclusion

Building a food factory is a complex but rewarding endeavor. From market research and site selection to equipment investment and regulatory compliance, every step must be carefully planned and executed. By prioritizing food safety, efficient operations, and sustainable practices, investors can achieve both profitability and credibility in the global food market.

Whether you are an entrepreneur planning your first facility or an established manufacturer expanding your production capacity, this guide provides the foundation for success. With the right strategy, your food factory can thrive in one of the world’s most dynamic industries.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?