🏭 1. Introduction

The commercial mayonnaise production line is a fully integrated, food-grade solution engineered for the mass production of emulsified sauces like mayonnaise, salad dressing, and other viscous condiments. It combines precise ingredient dosing, high-shear mixing, vacuum emulsification, and aseptic filling, ensuring product consistency, microbiological safety, and long shelf life.

This system is widely used by:

Large-scale food processing factories

Sauce brand manufacturers

Ready-to-eat meal factories

Central kitchens and condiment OEMs

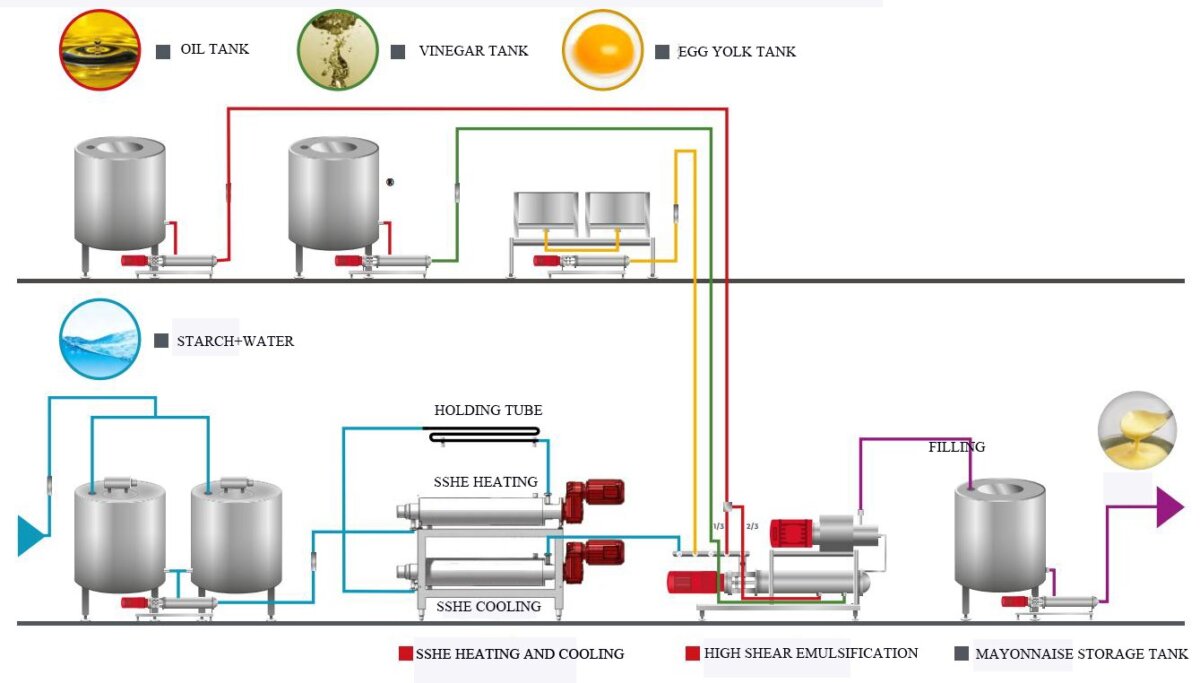

🍳 2. Process Flow Overview (Flowchart)

Raw Material Dosing → Water & Oil Phase Preparation → Vacuum Emulsification & Homogenization → Deaeration → Pasteurization (optional) → Cooling → Filling & Packaging → CIP Cleaning

Each step is automated and monitored via PLC-HMI control systems for optimal repeatability and hygiene.

⚙️ 3. Core Equipment & Specifications

| Equipment | Function | Key Specifications |

|---|---|---|

| Oil Tank | Stores edible oil; preheats if needed | SUS304/SUS316L, 200–3000L |

| Water Phase Tank | Prepares egg, vinegar, stabilizers | Agitated, heated |

| Vacuum Emulsifying Mixer | High-shear mixing under vacuum | 100–5000L, -0.09MPa, CIP-ready |

| High-pressure Homogenizer | Improves product texture | Pressure: 20–30MPa |

| Pasteurizer (Optional) | Inactivates bacteria to extend shelf life | Tubular or plate-type; 65–85°C |

| Cooling Unit | Lowers product temp to <20°C | Plate exchanger + chiller |

| Filling Machine | Volumetric or servo-driven | 500–10,000 jars/hr |

| CIP System | Fully automatic internal cleaning | Acid, alkali, hot water cycle |

| PLC Control System | Full process automation | Recipe control, real-time display |

📊 4. Production Capacity Options

| Model | Mixing Tank Volume | Output Capacity | Filling Speed (500g jars) |

|---|---|---|---|

| MPL-300 | 300L | 300 kg/h | 600–800 jars/h |

| MPL-1000 | 1000L | 1000 kg/h | 2000 jars/h |

| MPL-3000 | 3000L | 3000 kg/h | 6000 jars/h |

| MPL-5000 | 5000L | 5000+ kg/h | 10,000+ jars/h |

We also offer customized capacity options up to 10,000 kg/h for high-throughput factory needs.

🧭 5. Suggested Plant Layout (Simplified)

[Water Tank] [Oil Tank] ↓ ↓ [Emulsifying Mixing System] ↓ [Vacuum Homogenizer] ← [CIP Unit] ↓ [Pasteurization] → [Cooling] ↓ [Filling & Capping Line] ↓ [Labeling & Packaging]

👉 Full 2D/3D factory layout planning is provided, including:

Material flow zoning

Utility connection maps (steam, air, water, power)

Operator access paths

🧰 6. Customization Options

| Module | Custom Features |

|---|---|

| Mixing System | Batch or inline; vacuum or pressurized |

| Tank Material | SUS304 / SUS316L / food-grade PTFE |

| Heating Method | Electric, steam, thermal oil |

| Homogenizer | Optional 2nd-stage homogenization |

| Sterilization | Inline pasteurization or UV sterilizer |

| Packaging Format | Jar, pouch, sachet, squeeze bottle, bag-in-box |

| Control Interface | Siemens/HMI, remote monitoring, SCADA integration |

✅ 7. Advantages

High emulsifying stability: Prevents separation and oiling-off

Vacuum deaeration: Removes air bubbles, improving appearance and shelf life

CIP auto-cleaning: Minimizes downtime and meets HACCP/GMP standards

Customizable filling options: Compatible with glass, PET, and laminated packaging

Energy-efficient design: Low power consumption per kg of product

📦 8. Final Product Applications

Classic mayonnaise

Vegan or egg-free mayo

Spicy, herb-infused, or garlic mayo

Salad dressing and sandwich spreads

Export-grade condiments in jars, pouches, or sachets

📩 9. Value-Added Services

🛠️ On-site installation and commissioning

📚 SOP training for operators

🌍 Export-ready documentation (CE, ISO, UL available)

🔧 Lifetime spare parts support

Interested in a turnkey mayonnaise production solution tailored to your factory layout and target output?

➡️ Contact us for a personalized proposal, 2D/3D layout drawings, and a live equipment demo.

Must-read blogs for bosses