1. Overview

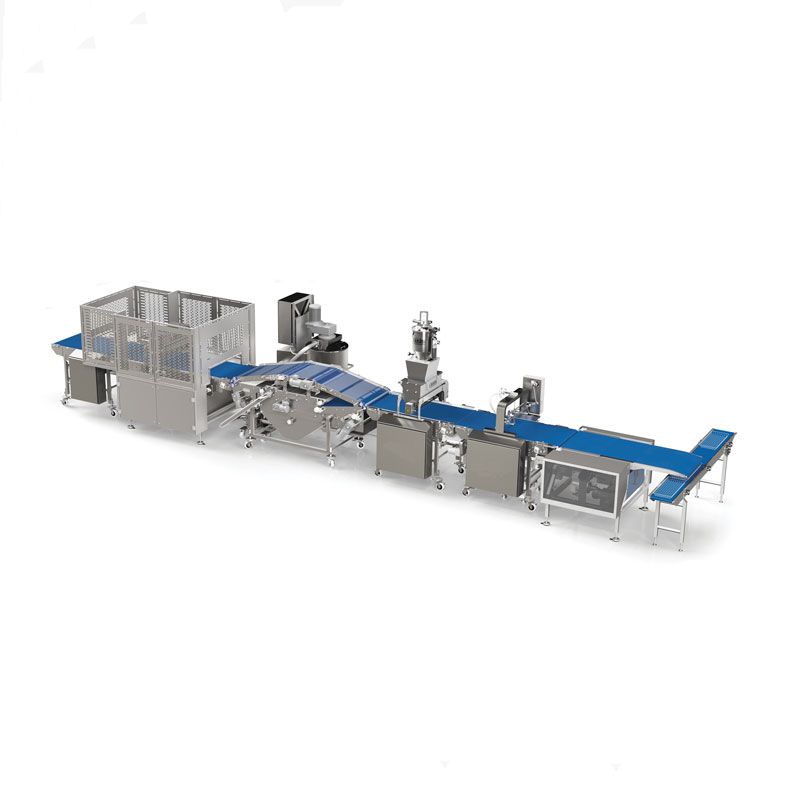

The Fully Automatic Donut Production Line is an integrated solution designed for mass production of various types of donuts, including yeast-raised donuts, cake donuts, mini donuts, filled donuts, and specialty shapes. It is widely used in commercial bakeries, frozen food factories, central kitchens, and OEM production lines.

The line supports automated processes for mixing, proofing, shaping, frying, cooling, coating, filling, and packaging — helping manufacturers improve productivity, consistency, and hygiene standards.

2. Production Process Flow

Ingredient Preparation → Mixing → Dough Forming → Proofing (for yeast donuts) → Frying → Oil Draining & Cooling → Glazing/Coating → Filling → Packaging

The workflow can be customized depending on the donut type (yeast or cake).

3. Production Capacity (Customizable Models)

| Model | Type | Capacity (pcs/hour) | Application Scope |

|---|---|---|---|

| DPL-200 | Cake-type | 200–600 | Small bakery/test line |

| DPL-1000 | Yeast or cake-type | 1,000–2,000 | Mid-size production |

| DPL-5000 | Yeast-type | 5,000–10,000 | Large-scale factories |

| DPL-10000 Plus | Multi-lane combo | 10,000–20,000 | Export-oriented plants |

4. Main Equipment Modules

Automatic Mixing System (spiral or twin-shaft mixers)

Dough Sheeting & Forming Machine (rolling, cutting, or extrusion)

Tunnel Proofing Chamber (humidity & temperature controlled)

Continuous Fryer (auto flipping, oil level & temperature control)

Oil Draining & Cooling Section

Glazing/Coating System (sugar icing, chocolate coating, sprinkles)

Filling Machine (jam, cream, chocolate, etc.)

Automatic Packaging Machine (bag, tray, or flow pack)

5. Customizable Options

| Module | Custom Features |

|---|---|

| Forming System | Rolling cut, extrusion, mold stamping |

| Donut Shapes | Round ring, heart, animal, mini balls, filled variations |

| Coating & Topping | Sugar icing, chocolate bath, nut sprinkling, powdered sugar |

| Packaging Style | Individual bags, blister packs, multi-packs |

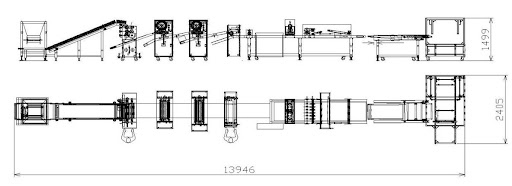

| Layout Design | Straight-line, L-shaped, U-shaped, or parallel-line layouts |

| Control System | Siemens PLC + touchscreen, remote monitoring, MES compatible |

6. Suggested Plant Layout Diagram

[Ingredients] → [Mixer] → [Forming] → [Proofing] → [Fryer] → [Cooling] → [Coating/Filling] → [Packaging] ↘—— (Oil draining + air cooling tunnel) ——↗

Note: Layout can be customized to fit your factory space.

7. Applicable Donut Types

Yeast-Raised Donuts

Cake Donuts

Jam/Cream-Filled Donuts

Mini Donuts

Custom Holiday or Branded Donuts

8. Key Advantages

🧠 Smart Control System: Multistage temperature, timing, and humidity control

🏭 Modular Architecture: Easy to scale or upgrade with interchangeable modules

🧼 Hygienic Design: Made of food-grade 304/316 stainless steel; HACCP & CE compliant

🛠️ Turnkey Installation Support: On-site setup, technician training, and remote diagnostics

📦 All-in-One Solution: From mixing to packaging, everything in one integrated line

9. Ideal For

Industrial-scale bakeries

Supermarket brand OEM/ODM lines

Frozen pastry exporters

Central kitchens of fast-food chains

Donut and pastry producers

10. Optional Deliverables

We offer the following documents and services based on your project:

✅ Detailed Quotation & Model Comparison

✅ Plant Layout Design in CAD/PDF

✅ Technical Proposal with Output Plan

✅ Overseas Installation & Training Guide

✅ Export Packaging & Compliance Documentation

Let us know your desired production capacity and layout constraints, and we will tailor the full proposal accordingly.

Must-read blogs for bosses