Beef Noodle Production Line - Chinese Manufacturer, Factory, Supplier

Commercial production of beef noodle products requires sophisticated beef noodle production line systems that simultaneously process protein components and pasta elements through coordinated manufacturing sequences. These integrated installations combine meat processing technology with noodle manufacturing equipment to create complete meal solutions at industrial scale.

Beef preparation initiates the beef noodle production line through primary processing stages including trimming, grinding, and seasoning operations. Industrial meat grinders featuring specialized plate configurations create uniform particle sizes while maintaining protein structure integrity. Temperature-controlled processing prevents protein denaturation during mechanical handling phases.

Protein conditioning involves marination systems where beef components absorb flavor compounds through vacuum tumbling or injection brining techniques. These processes enhance taste profiles while improving moisture retention characteristics essential for final product quality and shelf stability.

Noodle manufacturing occurs parallel to protein processing through dedicated pasta production equipment integrated within the beef noodle production line configuration. Continuous mixing systems combine flour, water, and binding agents to form homogeneous dough masses that feed into sheeting and cutting mechanisms.

Thermal processing represents the critical integration point where beef and noodle components undergo simultaneous cooking through steam injection systems or continuous belt cookers. These units maintain precise temperature profiles that ensure protein safety while achieving optimal noodle texture and moisture content.

Sauce preparation systems within beef noodle production line installations feature automated cooking vessels equipped with agitation mechanisms and temperature control systems. These units combine broth concentrates, seasonings, and thickening agents to create consistent flavor bases that complement both protein and starch components.

Assembly operations utilize automated dispensing systems that portion beef, noodles, and sauce components into packaging containers according to predetermined weight ratios. Volumetric or gravimetric filling mechanisms ensure consistent product composition while maintaining portion control accuracy.

Retort processing sterilizes assembled products through pressure vessel systems that achieve commercial sterility while preserving nutritional content and flavor characteristics. Temperature-time profiles eliminate pathogenic organisms while maintaining product integrity throughout shelf life periods.

Quality assurance protocols within beef noodle production line operations include microbiological testing, nutritional analysis, and sensory evaluation through automated sampling systems. These checkpoints verify product safety and quality consistency across production batches.

Modern beef noodle production line systems achieve throughput rates exceeding 1,200 units per hour while maintaining strict food safety standards and nutritional specifications. These installations incorporate clean-in-place systems, automated inventory management, and process control technologies that optimize efficiency while ensuring regulatory compliance throughout all manufacturing phases.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

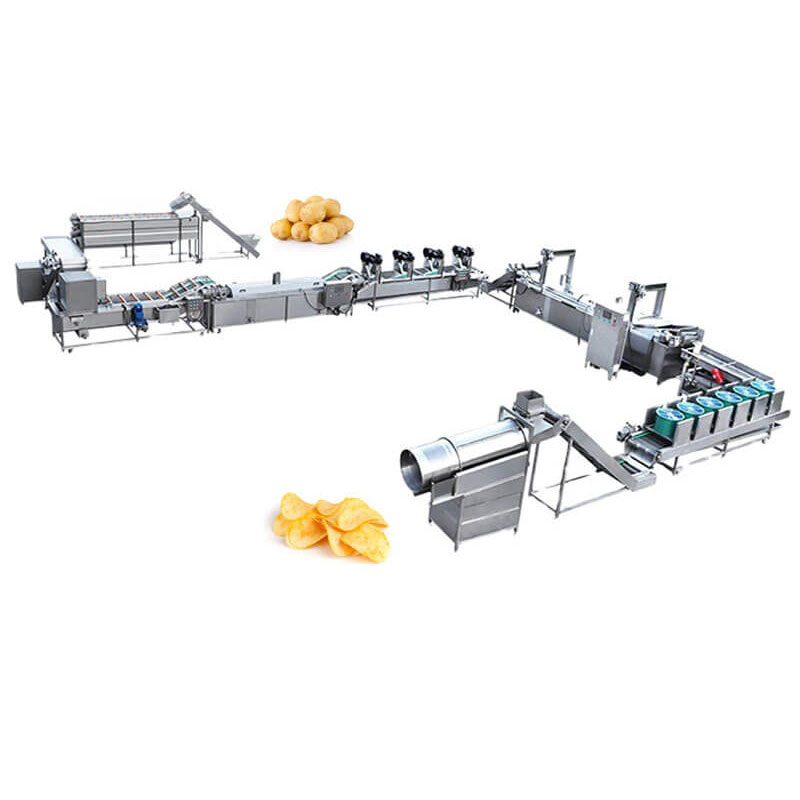

Meat Canned Food Production Line Crisp Production Line

Crisp Production Line Household Meat Grinder

Household Meat Grinder Meat Smoking Machine

Meat Smoking Machine Automatic Belt Frying Machine

Automatic Belt Frying Machine Double-Door Steaming Cabinet with Viewing Window

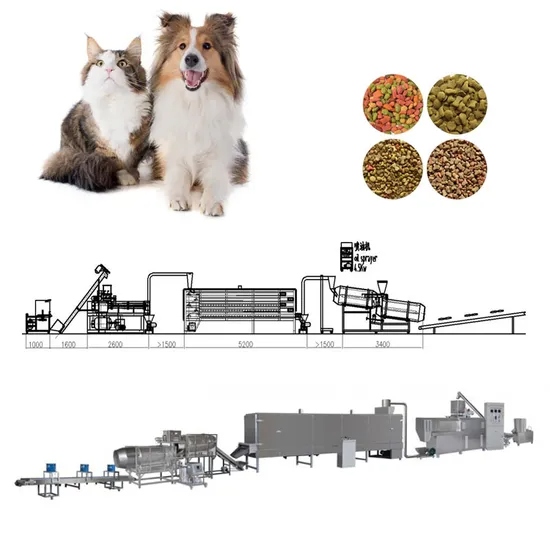

Double-Door Steaming Cabinet with Viewing Window Dry Pet Food Production Line

Dry Pet Food Production Line Jam Making Equipment

Jam Making Equipment