Boost efficiency, hygiene, and product consistency with our fully automated sandwich production line. Designed for industrial food manufacturers, central kitchens, and ready-to-eat (RTE) food suppliers, this line enables high-speed, large-scale production of sandwiches with minimal manual labor and maximum output quality.

✅ Product Overview

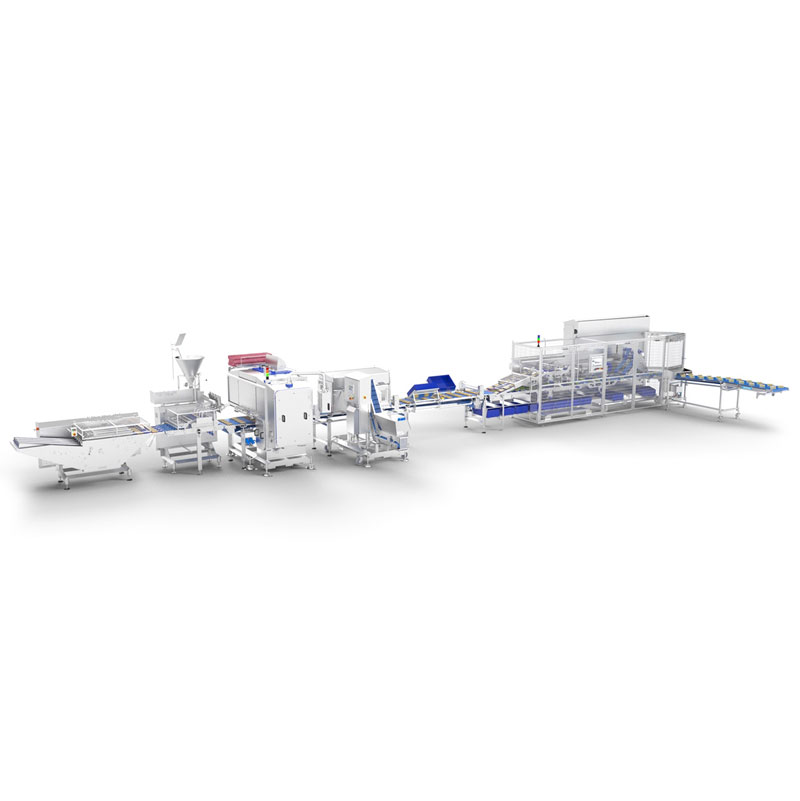

Our automatic sandwich production line integrates advanced food processing technologies to streamline every step of sandwich manufacturing — from bread slicing and sauce dispensing to ingredient loading, assembling, and final packaging. It is highly customizable and can be configured to meet your unique production needs and plant layout.

Ideal for producing:

Club sandwiches

Breakfast sandwiches

Vegan sandwiches

Triangle-cut sandwiches

Ready-to-eat (RTE) chilled or heatable options

🔧 Key Features

| Feature | Description |

|---|---|

| High Output Capacity | Up to 15,000 sandwiches per hour, suitable for large-scale food factories |

| Precision Automation | Robotic arms and visual sensors ensure exact positioning and portion control |

| Multi-Ingredient Support | Compatible with a wide variety of fillings (meat, cheese, vegetables, sauces) |

| Hygienic Design | Food-grade stainless steel (SS304/SS316), easy to clean and meets HACCP, GMP, and ISO22000 standards |

| Modular System | Adaptable layout with optional units for cutting, labeling, and wrapping |

| Energy Efficient | Optimized for lower power consumption with smart control logic |

🛠️ Production Flow

Bread Loading & Slicing

Automatically slices toast, buns, or custom-shaped bread at preset thickness.Sauce Dispensing

Viscosity-controlled system applies mayonnaise, mustard, or other sauces evenly.Ingredient Placement

Conveyor-driven or robotic loaders place meat, cheese, lettuce, eggs, and other ingredients precisely.Sandwich Assembly & Pressing

Top and bottom layers are aligned, pressed, and sealed if required (for heated products).Cutting & Edge Trimming (Optional)

Diagonal or rectangular cutting options for retail packaging.Automatic Packaging

Integrated with flow wrapping, tray sealing, or vacuum packaging systems.Metal Detection & Quality Inspection

Includes X-ray, metal detector, or AI-based vision inspection systems.

📐 Technical Specifications

| Parameter | Value |

|---|---|

| Capacity | 2,000 – 15,000 pcs/hour |

| Voltage | 380V / 50Hz (customizable) |

| Power | 15kW – 50kW depending on configuration |

| Layout Size | 8–25 meters length, modular layout |

| Control System | PLC + HMI Touchscreen |

| Cleaning Method | Modular disassembly or automated CIP system |

| Compliance | CE, HACCP, ISO22000, GMP |

📊 ROI & Operational Benefits

Investing in an industrial sandwich making line significantly reduces production costs and increases throughput.

Expected Outcomes:

↓ Labor costs reduced by up to 60%

↑ Daily output increased by up to 3x

↑ Consistency & product quality improved by 90%

↓ Contamination & recall risks lowered by 80%

🔄 Customization Options

Multi-layer sandwich units

Cold chain integration for chilled ingredients

QR code / batch number printers

Automated weighing and rejection systems

Remote monitoring & MES integration

Heat-sealing module for warm sandwiches

🌍 Application Scenarios

Food factories for retail chains

Supermarket ready-meal suppliers

Airline and railway catering suppliers

Hospital, school, and institutional kitchens

Export-focused food processors

📦 Turnkey Service Support

We provide:

On-site installation & training

Layout & capacity planning consultation

24/7 technical support & spare parts

Full documentation for compliance & export

🔎 Why Choose Us?

With 10+ years of experience in food processing automation, our sandwich production systems are trusted by global brands. We deliver tailor-made solutions, built to help you meet growing demand in the ready-to-eat food industry with less complexity, more control, and faster time-to-market.

Must-read blogs for bosses