Commercial Automatic Meat Blending Machine - Chinese Manufacturer, Factory, Supplier

A commercial automatic meat blending machine is an essential piece of equipment for butcher shops, meat processing plants, catering businesses, and food manufacturers aiming for high efficiency, consistent product quality, and precise ingredient mixing. Designed to handle large volumes of meat and additives, these machines automate the blending process, ensuring uniform texture and flavor across batches.

The main advantage of a commercial automatic meat blending machine is its ability to combine speed, precision, and hygiene. Built with heavy-duty stainless steel construction, food-grade components, and robust motors, these machines can operate continuously without compromising performance. They are ideal for blending various meats such as beef, pork, poultry, and seafood with spices, fillers, or marinades to create products like sausages, patties, meatballs, or ready-to-cook meals.

Efficiency is a critical factor. By automating the blending process, these machines reduce manual labor, improve production throughput, and ensure uniform distribution of seasonings and additives. Large-capacity hoppers and programmable mixing cycles allow operators to process hundreds or even thousands of kilograms per hour, meeting the demands of high-volume commercial and industrial operations.

Hygiene and safety are central to their design. Leading commercial automatic meat blending machines feature smooth surfaces, detachable mixing components, and easy-to-clean interiors. Compliance with HACCP, GMP, and ISO standards ensures food safety, while protective guards, emergency stop buttons, and interlocks protect operators during operation. Some machines also offer automated cleaning cycles, reducing downtime and improving operational efficiency.

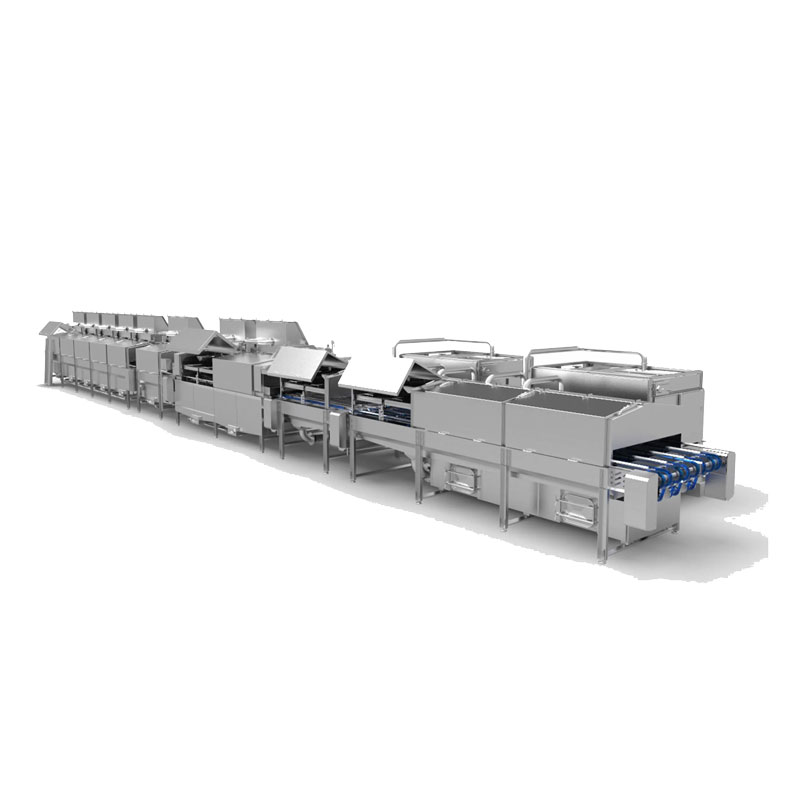

Modern models include programmable controls for batch sizes, mixing time, and speed adjustments, allowing precise customization for different recipes and product specifications. Advanced machines can also integrate with upstream and downstream equipment such as meat grinders, dicing machines, or sausage stuffers, creating a seamless production line for large-scale meat processing.

Different models cater to various business scales. Compact semi-automatic units are suitable for small butcher shops and restaurants, while fully automatic industrial machines serve large meat processing plants and food factories. Manufacturers typically provide installation support, operator training, spare parts, and technical service to ensure reliable operation over the long term.

Investing in a commercial automatic meat blending machine enables businesses to increase productivity, maintain consistent product quality, and reduce labor costs. With its robust construction, precise mixing capabilities, and compliance with food safety standards, this equipment is indispensable for modern meat processing operations, helping businesses meet growing consumer demand and maintain a competitive edge.

| Feature / Machine Type | Commercial Automatic Meat Blending Machine | Meat Mixer | Meat Grinder |

|---|---|---|---|

| Primary Function | Blend meat with seasonings, fillers, and additives uniformly | Mix meat and other ingredients, often for sausages or patties | Grind whole cuts of meat into smaller pieces or mince |

| Typical Output | Sausages, patties, meatballs, ready-to-cook blends | Sausages, meat patties, marinated mixes | Minced meat for burgers, sausages, or processed meat products |

| Capacity | Medium to high (100–2,000+ kg/h) | Small to medium (50–500 kg/h) | Small to industrial (50–1,500+ kg/h) |

| Blade / Mixing Type | Horizontal or paddle mixing blades | Paddle or ribbon mixers | Rotating blades with cutting plates |

| Adjustable Settings | Mixing speed, time, and batch size | Mixing time and speed | Grinding plate size for fineness |

| Automation Level | Semi-automatic to fully automatic | Manual to semi-automatic | Manual to fully automatic |

| Hygiene & Safety | Food-grade stainless steel, HACCP/GMP/ISO compliant, protective guards | Food-grade materials, easy-clean surfaces | Food-grade stainless steel, HACCP/GMP/ISO compliant, protective guards |

| Best For | Industrial meat processing, large-scale kitchens, catering factories | Restaurants, small to medium meat production | Butcher shops, restaurants, industrial meat processing |

| Key Advantage | Uniform mixing, precise control, high efficiency | Simple and flexible mixing | Efficient meat grinding, consistent particle size |

| Price Range | $5,000 – $50,000+ | $1,500 – $15,000 | $1,000 – $20,000+ |

Meat Canned Food Production Line

Meat Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine YL-W-05 Commercial Water Purification Equipment

YL-W-05 Commercial Water Purification Equipment Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Vegetable Processing Line

Vegetable Processing Line Multifunction Pasta Machine

Multifunction Pasta Machine Sausage Stuffer Machine

Sausage Stuffer Machine Frozen Food Production Line

Frozen Food Production Line Shrimp Processing Line

Shrimp Processing Line High-Speed Twisting Machine

High-Speed Twisting Machine