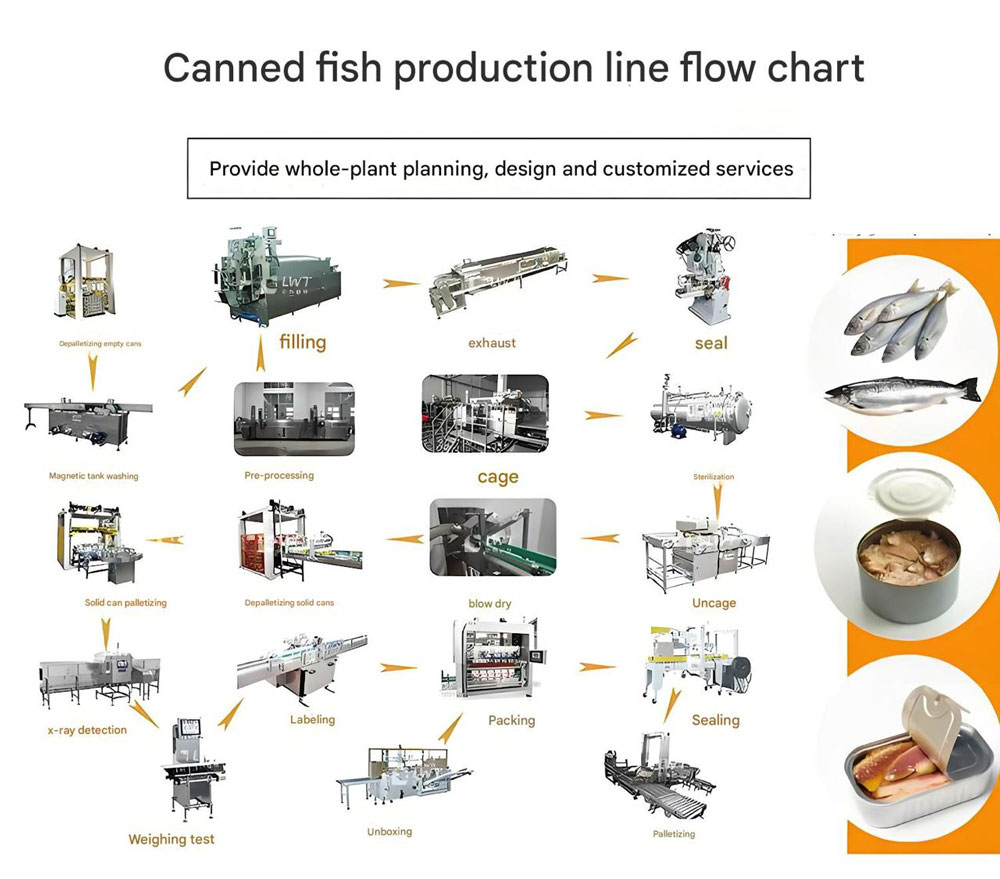

Production line process (raw material: sardines)

Raw material→thawing→conveying→cleaning→scaling machine→cutting head

and tail→removing viscera and conveying→cleaning→weighing and canning→boiling and

exhausting→draining→adding juice→vacuum canning machine→full can washing→cage

loading→sterilization→cage unloading→drying→labeling→inkjet printing→packing→warehousing

Raw water→sand core filtration→temporary storage→RO reverse osmosis→temporary storage→A

Empty cans→unstacking→cleaning→C

Equipment layout

Arrange according to the size of the other party's manufacturer's factory.

Equipment Technical Parameters

1. Thawing Tank

Material : Made of 2.0mm stainless steel plates.

Bottom Design : Equipped with a ¢38mm bubbling tube installed in a ring at the bottom.

Blower : 1.5KW blower installed at the bottom; tank is slightly inclined for easy waste discharge.

Waste Discharge Valve : Sanitary-grade butterfly valve.

Perforated Plate : Above the bubbling tube, there is a perforated plate (¢15mm, thickness 2.0mm).

Support Frame : Made of 4040 1.5 square tubes.

Other Components : All parts except the blower are made of SUS304 stainless steel.

Equipment Size : 20001000 800mm

Motor Power : 1.5KW (blower), 1.1KW, 380V/50Hz

2. Thawing and Cleaning Machine

Description : Uses bubbling, surfing, and water spraying at lifting points.

Filter Tank : One side has a filter tank to remove impurities.

Lifting Point Spraying : Clean water spray at net belt lifting point.

Equipment Size : 4500 x 1200mm (including 800mm net belt width)

Power : Motor: 0.75kW, Fan: 1.5kW, Circulation Pump: 1.1kW; 380V/50Hz

Material : Except motor, fan, pump, and rubber, all other parts are made of SUS304 stainless steel.

3. Skinning Machine

Function : Surface scaling of sardines after viscera removal.

Drum Design : Drum diameter 800mm, punching hole diameter 10mm.

Cleaning : High-pressure internal washing; water is recycled to tank.

Equipment Size : 35001200 1200mm

Power : Motor: 0.75KW, Pump: 1.5KW, 380V/50Hz

Material : Except motor and pump, all parts are SUS304 stainless steel.

4. Transfer Hoist

Conveyor Type : PU blue scraper belt conveyor, 600mm wide.

Transition Design : Lifts material 400mm to transition with head & tail cutting machine.

Frame : 4040 2mm square tube.

Main Power : 0.55KW, stepless speed regulation

Dimensions : 2400700 1200mm

Material : Except motor and belt, all parts are SUS304 stainless steel.

5. Head and Tail Cutting Machine

Design : Belt clamping synchronous conveyor.

Operation : Sardines are placed on belt conveyor and transported by clamping belt. High-speed rotating knives cut heads and tails.

Safety : Protective cover prevents splashing.

Size : 2400 x 1000mm (conveying chain: 600mm)

Power : Main motor: 1.1kW, tool motor: 2.2kW; 380V/50Hz

Material : Except motor and rubber, all parts are SUS304 stainless steel.

6. Viscera Removal Conveyor

Dual-Layer Design : Upper layer conveys sardines, lower layer conveys waste.

Upper Conveyor : White plastic modules.

Lower Conveyor : 3.0mm thick, 450mm wide sanitary belt.

Workbenches : Both sides have waste discharge ports.

Power : 1.5KW + 1.1KW, 380V/50Hz

Size : 60001200 1500mm

Material : Except motor and belt, all parts are SUS304 stainless steel.

7. Waste Conveyor

Function : Transports fish waste and viscera outdoors for centralized treatment.

Belt Thickness : 2.0mm.

Material : All parts except motor and belt are SUS304 stainless steel.

Size : 2000500 1200mm

Power : 0.75KW, 380V/50Hz

8. Bubble Cleaning Machine

- Same as No. 2 , but with higher power:

- Motor : 1.1kW

- Fan : 2.2kW

- Pump : 1.5kW

9. Salt Soaking Machine

Purpose : Soaks fish meat in brine to enhance flavor.

Design : Water tank with net belt conveying and stainless steel scraper lifting.

Power : 2.2KW, 380V/50Hz

Size : 45001200 1500mm

Material : Except motor, fan, and pump, all parts are SUS304 stainless steel.

10. Can Weighing Conveyor

- Double-Layer Structure :

- Upper Layer : Engineering chain plate for empty cans (478mm wide, 5000mm long)

- Lower Layer : For filled cans (478mm wide, 6000mm long)

Power : Upper motors: 0.55KW x2, Lower motor: 0.75KW

Size : 60001200 1400mm

Material : Except motor and chain plate, all parts are SUS304 stainless steel.

11. Steamer

Components : Frame, box, lid, conveying chain, steam pipe, reducer, etc.

Operation : Steam heats solid cans to above 80°C for exhaust.

Control System : Schneider electrical components, temperature-controlled

Power : 0.75KW, 380V/50Hz

Capacity : 2000 cans/hour

Size : 50001000 1400mm

Material : Except motor, mesh belt, and bearings, all parts are SUS304 stainless steel.

12. Canned Water Exchanger

Function : Inverts and drains canned food after steaming.

Design : Rotary table and drainage system for continuous production.

Power : 1.5KW, 380V/50Hz

Size : 4000 x 1000 x 1500mm

Structure : 60x60mm square tube frame, stainless steel chain and belt composite transmission.

13. Soup Adding Machine

Use : Adds soup to cans before sealing; excess soup is recycled.

Components : Chain conveyor, soup tank, spray pipe, recovery trough, beverage pump.

Size : 2000 x 800 x 1500mm

Power : 0.75KW, 380V/50Hz

Material : Except transmission parts, all parts are SUS304 stainless steel.

14. GT-250 Sealer

Type : Single-head automatic vacuum sealer.

Sealing Range : Diameter 52.3~98.9mm, height 34~124mm.

Features : Stable performance, quick change of can types.

Safety Devices :

Automatic brake if jammed.

Stops if no lid detected.

Power : 3KW (with brake), 24DC V

Weight : ~1800KG

**Size**: ~2200x1460x1900mm

**Vacuum**: 0.06~0.07MPa

Air Pressure : 0.5~0.8MPa

15. Tank Cleaning Machine

- Two-Stage Cleaning :

- Stage 1: Hot water with detergent (recycled).

- Stage 2: Final rinse with hot water (recycled).

Power : 2.75KW

Size : 3000750 1500mm

Material : Except motor and nozzle, all parts are SUS304 stainless steel.

16. Manual Loading and Unloading Cage Conveyor

Hydraulic Lifting : Fills sterilization frames manually, then pushed into sterilizer.

Unloading : Hydraulic lift lowers basket, cans pushed onto conveyor.

Loading Power : 4KW

Unloading Power : 3KW

Size : 3000 x 1000 x 1200mm

17. High-Temperature Horizontal Sterilizer

- Features :

- Low steam consumption.

- Fast heating/cooling.

- Even temperature distribution.

- Four temperature probes.

- Pressure control to minimize packaging deformation.

Heating Method : Steam

Tube Size : Inner diameter 1200mm, length 3200mm, wall thickness 5mm

Size : ~2000 x 1200 x 1500mm

Control : Computer semi-automatic, 16.5KW

Pressure : Design 0.35MPa, Test 0.44MPa, Max working 0.30MPa

Temperature : Up to 147°C

18. Transfer Cart

Use : Shuttles between sterilizer, loading, and unloading machines.

Material : SUS304 stainless steel.

Wheels : Silent nylon wheels.

19. Sterilizing Basket

Material : SUS304 stainless steel, 2.0mm thick.

Design : Movable bottom plate, reinforced frame.

20. Dryer

Function : Dries cans after sterilization to avoid rust spots.

Capacity : 0~150 cans/min

**Applicable Can Size**: Diameter Φ52.5~105mm, Height 32~133mm

Power : 4KW

Size : 2000 x 650 x 1500mm

21. Inkjet Printer

Use : Prints date and batch number on cans.

Capacity : 0~200 cans/min

Use Cases : Cans, PET bottles, glass bottles

Power : 0.05kW

Size : 500x500x1200mm

22. Packaging Conveyor

Chain Plate : Engineering plastic (POM), brown color, 82mm wide.

Frame : SUS304 stainless steel, 2.0mm thick.

Side Panel Height : 160mm.

Transmission : Worm gear reducer motor (0.75KW–0.55KW).

Guardrail : Plastic, legs: SUS304 stainless steel.

23. Transfer Tank

Capacity : 800L

Material : SUS304, δ=2mm, outer cover 1.5mm

Surface Treatment : Inner polished 300MESH, outer 2B matte

Top : Fully enclosed with manhole, ladder, dust-proof vent

Insulation : Polyurethane foam, 60mm thick

Accessories : Glass level gauge, CIP cleaning head

Agitation : Miller jacket, 0.2MPa steam, 60rpm vertical stirring

Valve : Adjustable height foot, bottom valve height 600mm

24. Buffer Tank

Same as No. 23 , without agitation system.

25. Sanitary Pump, Pipes & Valves

Function : Connects soup preparation and filling systems via sanitary pumps.

26. Empty Can Management Machine

Design : Disc-type can sorting system.

Disc Diameter : 1100mm.

Sorting : Guides cans into single file; extras return to disc.

Power : 0.37KW, electromagnetic speed control

Size : ¢12001000mm

Frame : 40 40*2mm square tube

27. Magnetic Empty Can Washer

Function : Automatically washes empty metal cans.

Design : Magnetic flipping device and inner wall spray cleaning.

Size : 2500 x 750 x 1100mm

Material : Except motor, rubber strip, and bracket, all parts are SUS304 stainless steel.

Must-read blogs for bosses