The best deep-fried instant noodle production line from China offers numerous advantages, including advanced technology, high production capacity, low energy consumption, and a high level of automation. From the ripening process to the cooling stage, the entire line integrates touchscreen presetting, photoelectric tracking, frequency control, and PLC program control. It supports independent fine-tuning, full-line interlocking, and synchronized acceleration and deceleration control.

The production line achieves coordinated synchronous control throughout, with digital display of cutting frequency and continuous adjustment of noodle piece weight without stopping the line. It also features automatic frying temperature control, ensuring safe and reliable operation, convenient maintenance, low oil content in the final noodle cakes, and a high product qualification rate.

The dough mixer employs an elliptical blade, dual-shaft, dual-speed mixing technology, allowing for a higher water absorption rate and more uniform hydration of the raw materials. The ripening machine uses static dough resting technology to ensure consistent dough maturation. The pressing machine is equipped with 9 pairs of chilled hard alloy rollers, enhancing sheeting quality and efficiency.

Additionally, an advanced soaking flavoring technique is applied after steaming to improve flavor penetration. All surfaces that come into contact with food are made of stainless steel and food-grade materials, meeting stringent food hygiene standards.

The resulting noodles are known for their delicious taste, crisp texture, smooth mouthfeel, and excellent chewiness.

| Model No. | Production Capacity | Steam consumption (Kg/hour) | Factory Size (L×W×H) (m) | Width of Roller(mm) | Installed capacity(kw) | Workers |

| HSYL-3Y | 30,000 blocks/8 hours | 1000-1200 | 60×4×4.5 | 216~260 | 42 | 4 |

| HSYL-6Y | 60,000 blocks/8 hours | 1200-1400 | 66×6×4.5 | 300~330 | 56 | 4 |

| HSYL-8Y | 80,000 blocks/8 hours | 1300-1500 | 66×6×4.5 | 420~450 | 68 | 6 |

| HSYL-10Y | 100,000 blocks/8 hours | 1400-1600 | 75×7×5.0 | 420~450 | 80 | 6 |

| HSYL-12Y | 120,000 blocks/8 hours | 1800-2000 | 75×8×5.0 | 510~550 | 83 | 6 |

| HSYL-16Y | 160,000 blocks/8 hours | 2000-2400 | 90×8×5.5 | 630~650 | 106 | 7 |

| HSYL-18Y | 180,000 blocks/8 hours | 2400-2600 | 110×9×5.5 | 720~730 | 114 | 7 |

| HSYL-20Y | 200,000 blocks/8 hours | 2600-2800 | 120×9×5.5 | 765~800 | 125 | 8 |

| HSYL-25Y | 250,000 blocks/8 hours | 3000-3200 | 120×9×5.5 | 870~900 | 140 | 8 |

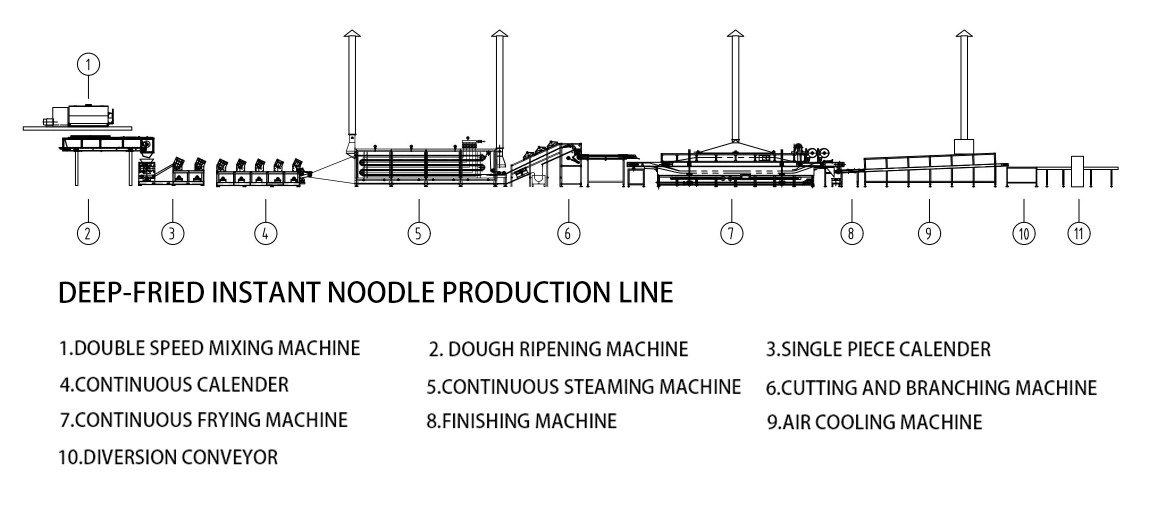

Fried Instant Noodle Production Processing Line

The fried instant noodle production process is fully automated and precisely controlled to ensure high efficiency, product consistency, and food safety. The complete processing line includes the following key stages:

Automatic Material Supplying

Ensures continuous and stable feeding of raw materials into the production system.Mixing & Metering of Salt & Water

Precise metering and uniform mixing of salt and water to prepare the brine solution for dough making.Double-Shaft Double-Speed Dough Making

Utilizes an advanced elliptical blade system for thorough and uniform hydration of flour, enhancing dough quality.Dough Ripening

Static dough resting technology ensures consistent gluten development and improved texture.Compound Rolling & Continuous Rolling

Multi-stage rolling with chilled rollers to form a uniform dough sheet.Slitting & Forming

Precision cutting and shaping of noodles into desired forms (e.g., wavy or straight).Steaming

Fully cooks the noodles to achieve proper gelatinization of starch.Cutting & Dividing

Accurate portioning of noodle blocks before frying.Frying

Deep-frying in oil to achieve crispness and long shelf life, with automatic temperature control for consistency.Cooling

Rapid and even cooling to stabilize the product before packaging.Conveying

Smooth transfer of finished noodle cakes to the packaging station.Packaging

Automated packaging ensures hygiene, accuracy, and efficiency.Warehousing

Final products are stored in a controlled environment ready for distribution.

Must-read blogs for bosses