Automated Meat Processing Equipment - Chinese Manufacturer, Factory, Supplier

The evolution of meat manufacturing has shifted toward higher speed, accuracy, and hygiene, making Automated Meat Processing Equipment a cornerstone of modern production facilities. These advanced systems integrate cutting-edge technology to handle large volumes of meat with minimal manual intervention, ensuring consistent quality and operational efficiency.

Comprehensive Automated Meat Processing Equipment solutions cover every stage of the workflow—cutting, deboning, grinding, mixing, forming, marinating, and packaging. Each module is designed to work seamlessly within a connected line, enabling continuous production and reducing bottlenecks.

At the core of these systems is intelligent automation. PLC-controlled operations, servo-driven cutting systems, automated feed conveyors, and real-time process monitoring enable precise control over portion sizes, texture, and output rates. This not only reduces labor costs but also eliminates human error, improving product consistency.

Hygiene and food safety remain paramount. Premium Automated Meat Processing Equipment is built from food-grade stainless steel with seamless welds and easy-to-clean surfaces. Components are designed for quick disassembly and full washdown, meeting HACCP, ISO 22000, and USDA compliance requirements.

Scalability is another advantage. Automated systems can be configured to handle multiple meat types—beef, pork, poultry, and lamb—while adapting to varying production capacities. Modular designs and interchangeable tooling make it simple to introduce new product lines or adjust to changing market demands without significant downtime.

Beyond the machinery, leading suppliers of Automated Meat Processing Equipment provide tailored integration services, operator training, preventive maintenance plans, and rapid parts availability. This ensures optimal performance and minimizes unexpected stoppages.

For meat processors aiming to reduce costs, increase yield, and maintain top-tier product quality, investing in Automated Meat Processing Equipment delivers a competitive edge—turning complex production requirements into streamlined, high-output operations.

Automatic Fish Filleting Machine

Automatic Fish Filleting Machine Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Two-Stage Feeding (Minimum Height) Vertical Packaging System

Two-Stage Feeding (Minimum Height) Vertical Packaging System Multifunctional Food Packaging Machine

Multifunctional Food Packaging Machine Smoked Furnace

Smoked Furnace Meat Shredding Machine

Meat Shredding Machine SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Pasta Production Line

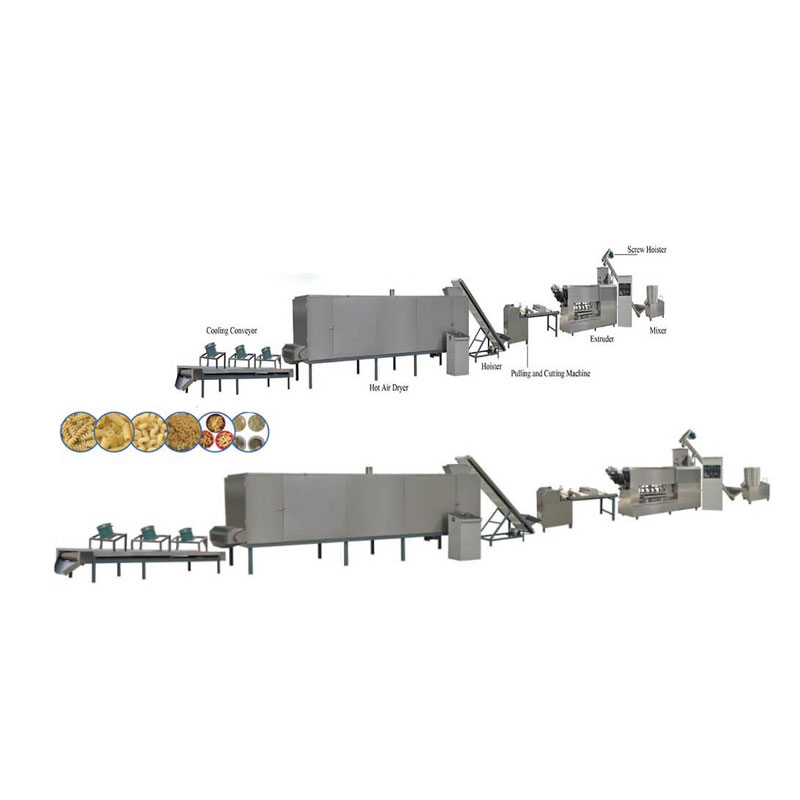

Pasta Production Line