Fully Automatic Production Line For Short-Cut Pasta - Chinese Manufacturer, Factory, Supplier

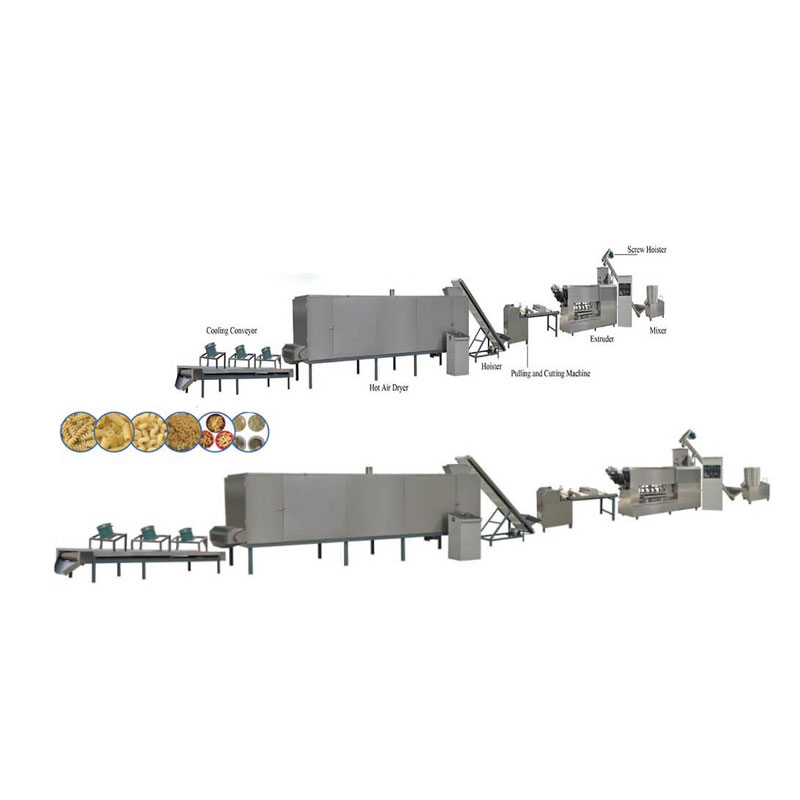

A fully automatic production line for short-cut pasta is engineered to meet the demands of industrial-scale pasta manufacturing, delivering precision, efficiency, and consistency throughout the entire process. Designed for producers aiming to achieve high output with minimal labor, these systems integrate advanced technologies that cover every stage of pasta production—from raw material preparation to final drying and packaging.

The process begins with automated mixing and kneading systems that blend semolina or flour with water to create a uniform, high-quality dough. The dough is then fed into extrusion units equipped with interchangeable dies, allowing manufacturers to produce a wide variety of short-cut pasta shapes such as penne, fusilli, rigatoni, macaroni, and farfalle. Cutting mechanisms ensure exact sizing, while pre-drying and drying tunnels regulate temperature and humidity to preserve texture, cooking performance, and shelf life.

A fully automatic production line for short-cut pasta offers precise process control through PLC systems, touchscreen interfaces, and real-time monitoring, enabling operators to adjust parameters quickly and maintain consistent quality. Constructed from food-grade stainless steel, the equipment meets international standards for safety and hygiene, including HACCP and ISO22000. CIP (clean-in-place) technology ensures simple sanitation and minimal downtime.

Flexibility and scalability are central to these production lines. Manufacturers can configure systems to match production capacity, from medium-sized facilities to large-scale industrial plants. Optional add-ons, such as automatic packaging machines, metal detectors, or quality inspection systems, allow seamless integration into turnkey solutions.

For pasta producers, investing in a fully automatic production line for short-cut pasta translates into higher efficiency, reduced labor costs, and consistent output. It enables businesses to respond to growing global demand while maintaining strict quality control and ensuring consumer satisfaction.

By combining automation, energy efficiency, and robust engineering, these production lines provide a long-term solution that enhances productivity, supports product diversification, and strengthens competitiveness in the international pasta market.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Production Line

Pasta Production Line Pasta Machine

Pasta Machine Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Multifunction Pasta Machine

Multifunction Pasta Machine High-Speed Twisting Machine

High-Speed Twisting Machine Gizzard Peeling Machine

Gizzard Peeling Machine Double-Door Sterilizer

Double-Door Sterilizer Flake Ice Machine

Flake Ice Machine Automatic Meatball Making Machine

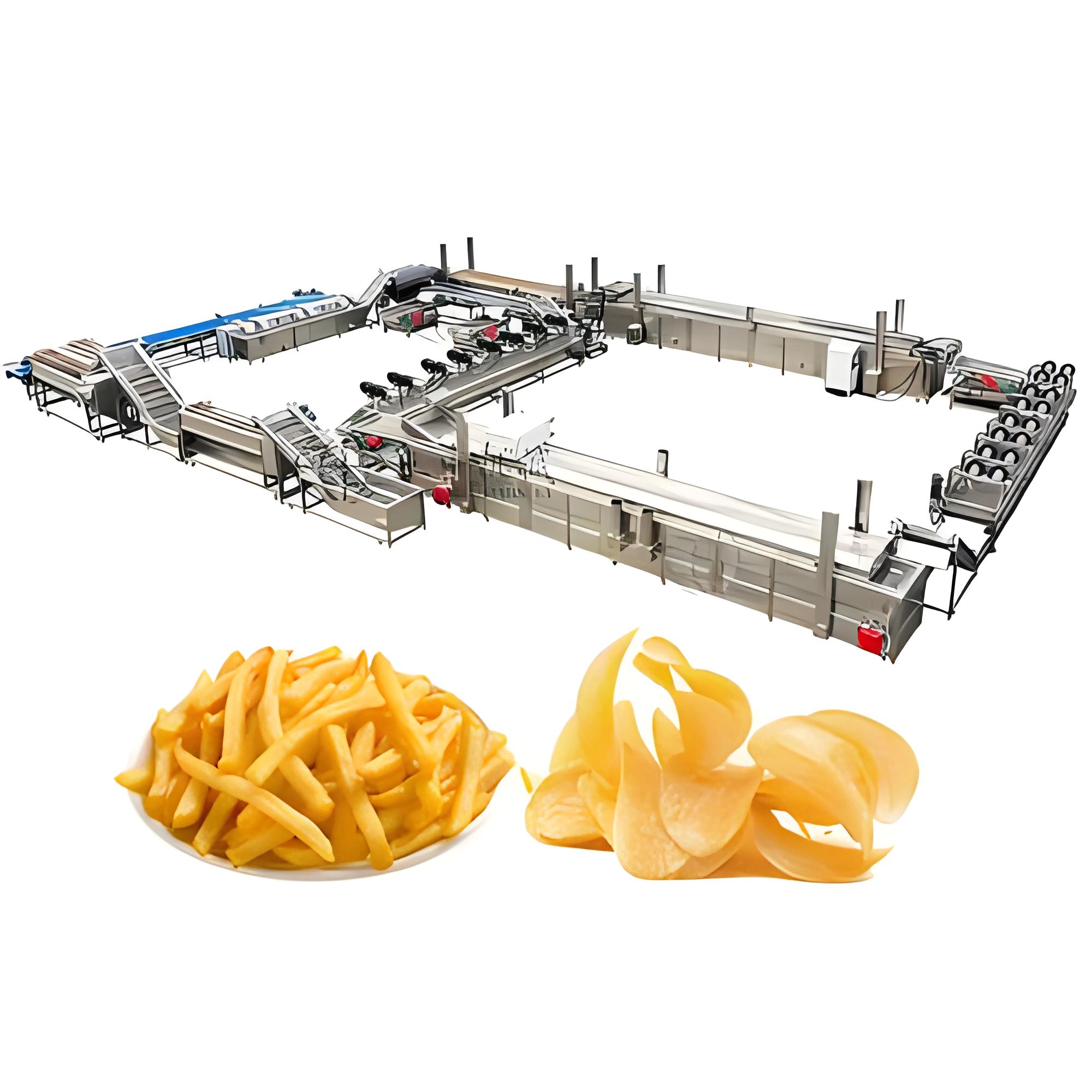

Automatic Meatball Making Machine French Fries Production Line

French Fries Production Line Dough Roller Machine

Dough Roller Machine Fish Food Processing Line

Fish Food Processing Line